Economically Selection

A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging.

Unrivaled Degassing

Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency.

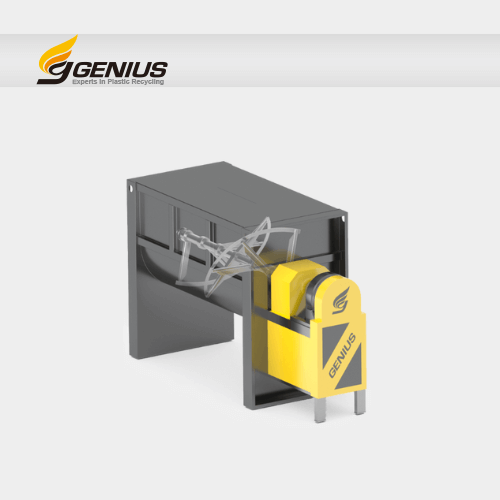

Exhaust-Free Construct

The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke.

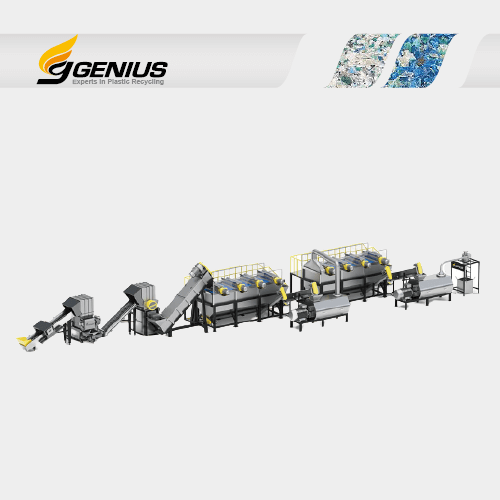

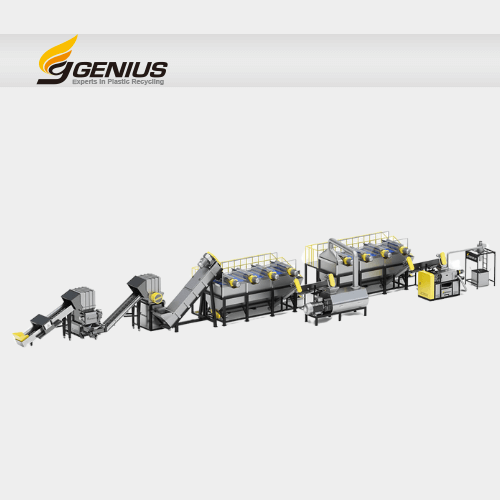

Better Flexibility

Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant.

Cost Saving

Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant.

| Model | H-DFC-100i | H-DFC-125i | H-DFC-150i | H-DFC-175i | |

| H-SPR-100i | H-SPR- 125i | H-SPR-150i | H-SPR-175i | ||

| Extrusion capacity | 200-300 kg/hr | 300-450kg/hr | 450-600 kg/hr | 700~900 kg/hr | |

| Main extruder | Screw diameter | Φ100 mm | Φ125 mm | Φ150 mm | Φ175 mm |

| Motor | 125HP | 150HP | 200HP | 350HP | |

| Sub extruder | Screw diameter | Φ115 mm | Φ135 mm | Φ165 mm | Φ185 mm |

| Motor | 50HP | 60HP | 75HP | 100HP | |

- Our screw is made of wear resistance materials. Ensure the longevity of product life.

- Extruder is equipped with pressure sensors. Pressure sensor will give notification of changing filter screen as necessary automatically. User-friendly.

- Bottle fragments, rigid and dried materials are preferable.

- Smooth running of the machine

Strand pelletizing

Mainly designed for high viscosity materials.

Individually extruded strands will be cooled down in a water cooling tank and then be cut by a pellet cutter.

Hot Die Face pelletizing

Compared to strand pelletizing, it saves labor cost of drawing strand.

Hot die face pelletizing system is a universal joint design. Dust-free.

Die face cutting makes perfect unity of plastic pellets.

PET, PP, PS, PE, ABS, HIPS, and more. Suitable for plastic rigid materials, including crushed bottles, crushed industrial waste.

|

|

|

| Industrial Waste | Rigid Waste | Washed Bottles |

|

|

|

| Washed Greenhouse Films | Washed Plastic Automotive Parts / ABS Recycling | Washed WEEE Waste Electrical Equipment |