Increasingly Feeding

The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%.

More Labor-saving

The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant.

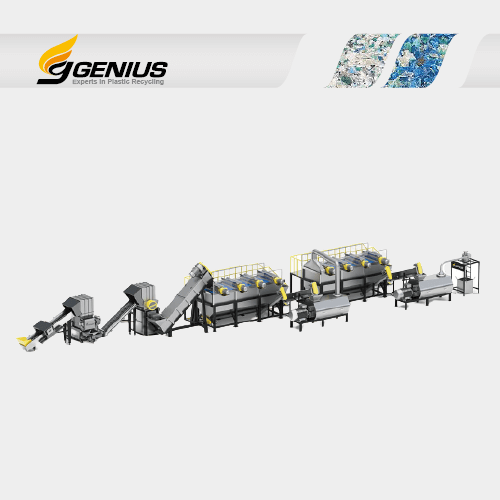

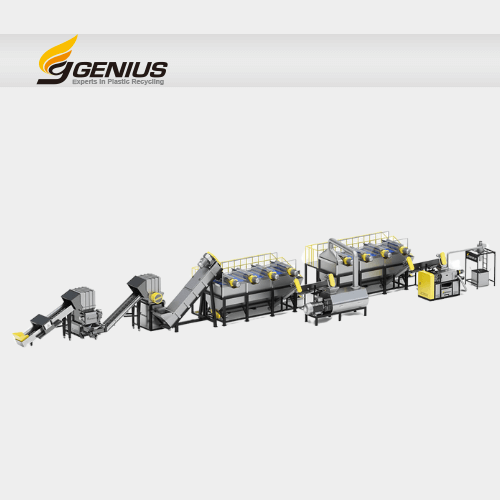

Better Flexibility

Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant.

OUTSTANDING PERFORMANCE

Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant.

| Model | RECO-85 | RECO-100 | RECO-125 | RECO-135 | RECO-150 | RECO-175 | |

| Screw diameter | Φ85 mm | Φ100 mm | Φ125 mm | Φ135 mm | Φ150 mm | Φ175 mm | |

| Main Drive | 75HP(56KW) | 125HP(94KW) | 175HP(131KW) | 200HP(150KW) | 200HP(150KW) | 300HP(262KW) | |

| Output | 200~300 ↑ kg/hr | 300~400 ↑ kg/hr | 450~600 ↑ kg/hr | 650~850 ↑ kg/hr | 700~800 ↑ kg/hr | 900~1100 ↑ kg/hr | |

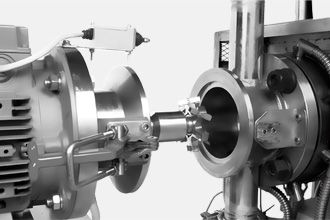

Hot Die Face pelletizing

Die-face pelletizing is expected to reduce manpower cost.

Pelletizing system is a universal joint design. Dust-free.

Die face cutting ensures the final plastic pellets in uniform size.

Underwater pelletizing

Uniquely designed for high viscosity materials.

Cutting and cooling at a time.

Strand pelletizing

High viscosity materials are preferable.

Individually extruded strands will be cooled down in a water cooling tank and then be cut by a pellet cutter.

- Durable material: wear-resistant screw

- Plastic films, clean and wet materials are preferable to single extruder.

- Low noise and steady operation.

PET, PP, PS, PE, ABS, HIPS and more. Suitable for plastic rigid materials, including crushed bottles, crushed industrial waste.

|

|

|

| Chemical Drums | HDPE Milk Bottles | Injection Mold Gate And Runner |

|

|

|

| PET Drink Bottles | PP Battery Case | WEEE Waste Electrical Equipment |

RECO-Y-150i / Force Side Feeding Plastic Recycling Machine / HDPE bottle / Taiwan

It’s time to kick out your old fashion equipment!

In late November, 2017, the fifth RECO series pelletizers started to be processed in Taichung.

The major material for this client to recycle is HDPE bottle. In the past, 175mm screw was used in the old type. The output capacity only could reach 500kg per hour. After the brand new RECO-Z-150i was installed, the screw diameter only 150mm measured. The output capacity can reach 1100kg per hour.

Comparing with old one, it only needs the same motors with the old type. And its screw is much smaller and lower energy consumption. The most important of all, the output capacity was doubled than the old style one.

How does it work?

RECO series-Force side feeding device: Its stable and continuous feeding measure assures the maximum efficiency.

Z type connection: The main and sub extruder are now connected which solves the overflow problem and prevents the material from getting stuck in the sub extruder’s hopper.

Triple Degassing: After washed HDPE bottle flakes usually remain an extent of moisture. Through the triple degassing device with special design, the pellets won’t have a cavity inside.

https://www.youtube.com/watch?v=rpC9iNN3tm4

RECO-Z-125i / Force Side Feeding Plastic Recycling Machine / Washed PE Film / Taiwan

Now, labor costs are more and more expensive. And the environmental awareness is rising. Genius always takes the customer’s perspective into consideration when developing machine and so we have launched our newest product - RECO-Z series two stage plastic recycling machine.

RECO-Z’s Four Top Features

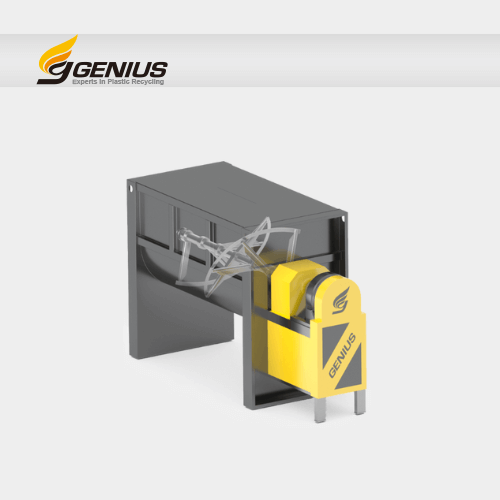

Feature 1: Force type side feeding system.

It has a smaller motor but has higher output capacity! For example, the one in the picture below has a 7.5Kw motor and the output capacity can reach up to 450 kg/hr.

Feature 2: Force type two-stage extruder.

This is a unique two stage recycling machine which is the first of its kind in the market. The main and sub extruder are now connected which solves the overflow problem and prevents the material from getting stuck in the sub extruder’s hopper.

In addition, melted plastics do not leak or contact the air anymore. No more excess gas is emitted, so therefore, NO MORE POLLUTION!

Feature 3: Z-type arrangement.

Effectively saves space and manpower! ONLY NEED 1 OR 2 WORKERS to operate the whole set of Z-series!

Feature 4: High precision compounding screw design.

It’s final product has good stretch quality and it reduces the loss of its chemical properties. The final product has many uses. It can be used to blow bags or to make raffia.

“The quality of the pellets from this machine is very good which significantly raises the price of recycled pellets. Furthermore, it saves lots of cost.” Mr. Chung, CEO of Donfung Plastic said, “I decided that all production lines in our second factory are going to install this type of machine.” Donfung Plastic is Taiwan’s biggest PE film recycler. Their production capacity per month is up to 2,500 tons. They installed 2 sets of recycling lines and ordered 2 more sets from Genius. The next 2 sets are going to be installed this April 2017.