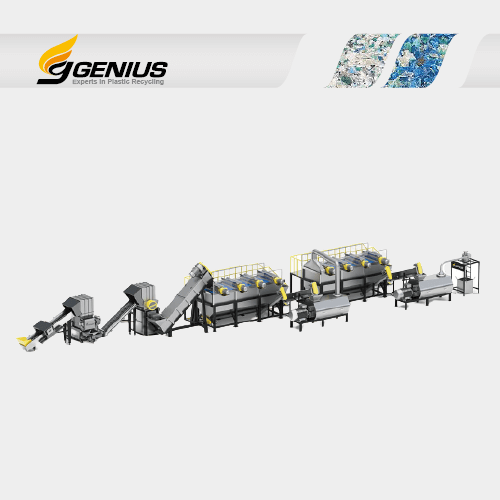

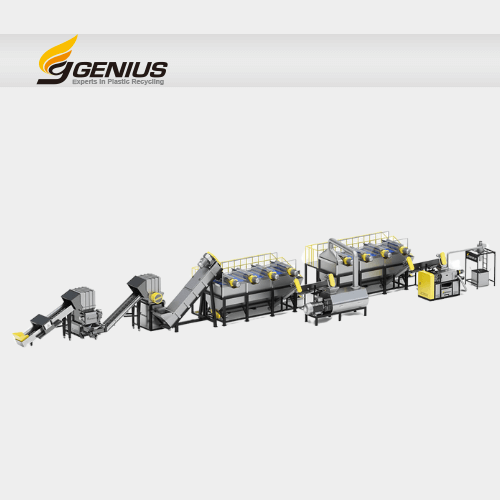

High-Efficiency Washing System

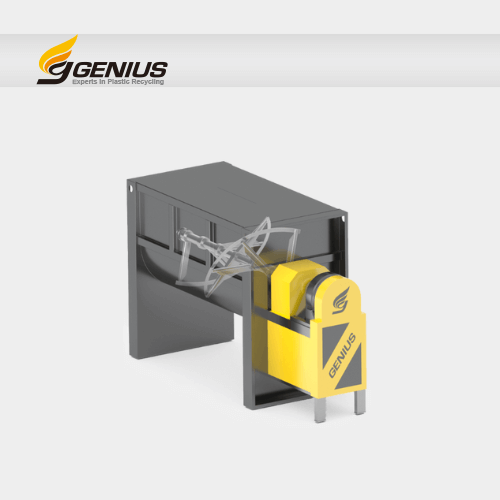

The rigid plastic wastes to be fed into automatic production systems. After shredding, crushing, washing, and drying. The finished product could be fed into pelletizing systems to produce plastic pellets and create a bigger profit.

The rigid washing plants are designed for recycling post-consumer hard materials like bottles, injection waste, or rigid materials. These systems produce uniform plastic flakes with high purity and low moisture level.

Bottles Plastic Drums Recycling

HDPE Milk Bottles Industrial Pipes

ABS Plastic Shredder For Automotive Parts Washed WEEE Plastic Recycling