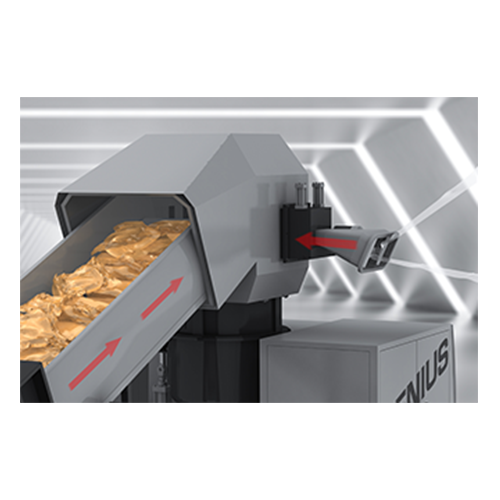

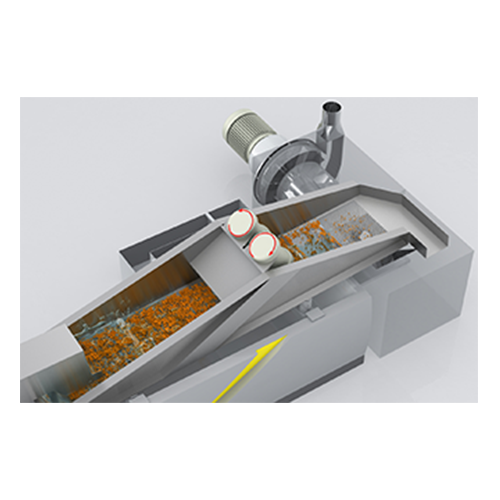

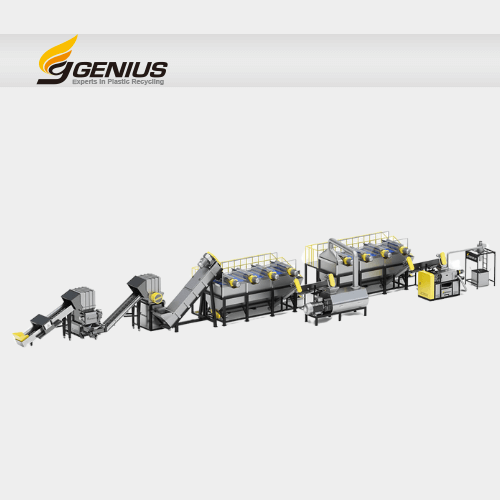

Compacting & feeding

The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity.

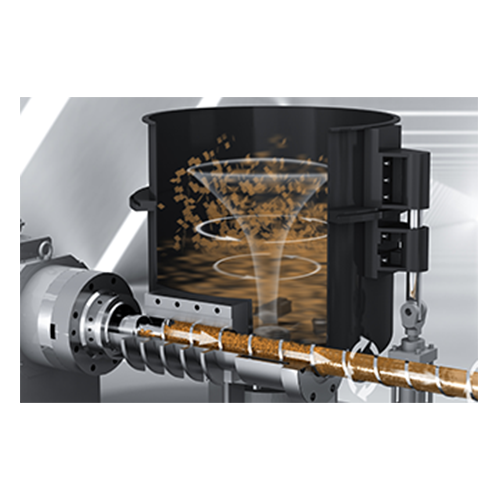

Multiple Cooling

Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

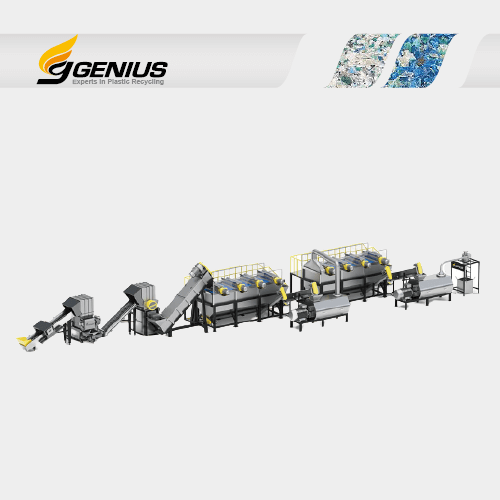

Better Flexibility

Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant.

Cost Saving

Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant.

| Model | KR-65 | KR-85 | KR-100 | KR-125 | KR-135 | KR-150 | KR-175 | |

| Screw | Ø65 mm | Ø85 mm | Ø100 mm | Ø125 mm | Ø135 mm | Ø150 mm | Ø175 mm | |

| Main drive |

40HP (30KW) |

75HP (56KW) |

125HP (94KW) |

175HP (131KW) |

200HP (150KW) |

250HP (188KW) |

350HP (262KW) |

|

| Compactor drive |

30HP (23KW) |

60HP (45KW) |

75HP (56KW) |

100HP (75KW) |

125HP (94KW) |

150HP (112KW) |

175HP (131KW) |

|

| Output (kg / hr) | 80 ~ 100 ↑ | 200 ~ 300 ↑ | 300 ~ 400 ↑ | 450 ~ 600 ↑ | 650 ~ 850 ↑ | 700 ~ 800 ↑ | 900 ~ 1100 ↑ | |

PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc. Especially for plastic films, foam, woven, raffia, wash & squeezed films, flakes, edge-trimmed, and cutting-edge materials

|

|

|

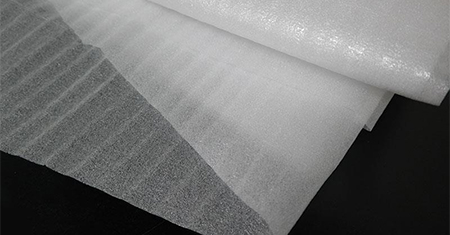

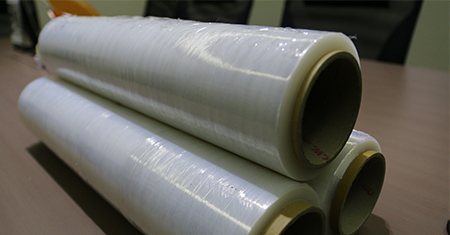

| EPE Foam Recycling Machine | Films | HDPE Bags Recycling |

|

|

|

| Non-Woven Fabric | Plastic Raffia | Zipper |

-

Energy Saving:

We use speed reducer motors from Germany. Statistics show that energy can be saved by 20%.

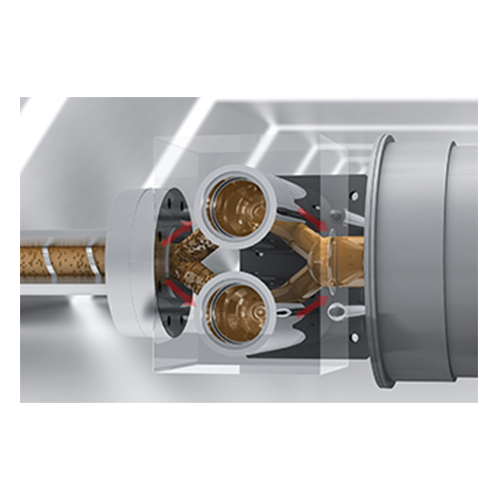

- Space Saving: 3 in 1 plastic recycling machine integrates shredding, extruding and pelletizing into one machine. Besides, the hot die-face pelletizing reduces the labor cost of drawing strands. Without water cooling bath, 3 in 1 plastic recycling machine takes less space.

-

Efficiency Improvement:

Dual pistons hydraulic screen changers keep the machine operating nonstop even when replacing the filter screen. It greatly increases overall throughput and minimizes the chance of waste.

-

Overall benefits of Our Machine:

Low operating cost

Easy operation

High output

KRIEGER-150 / CUTTER COMPACTOR PLASTIC RECYCLING MACHINE / BOPP FILM / KOREA

In the beginning of 2019, GENIUS installed a new Plastic Recycling machine in Korea.

The customer used to own a Korean machine with strand pelletizing system. However, its capacity only 300kg/hr. Year by year, the labor cost is becoming much higher. Due to above reasons, the customer decided to improve the efficiency of his production line.

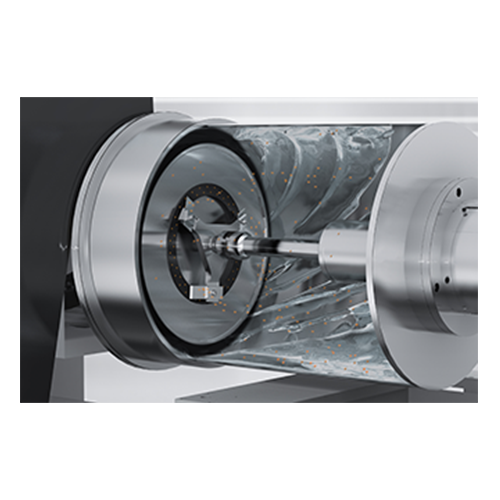

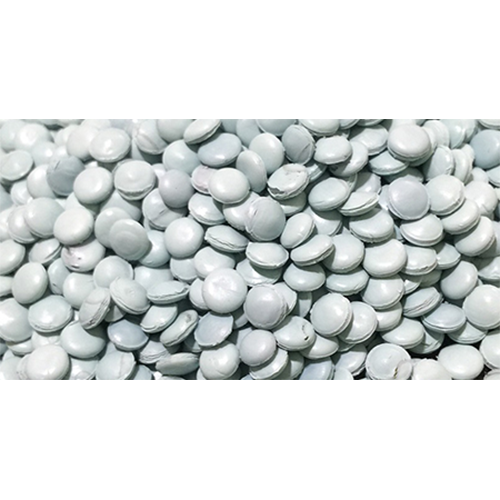

Generally, PP pellets were never been made by hot die cutting device in Korea. The customer thought it’s impossible. Therefore, the GENIUS team developed the special designed die face cutter which can pelletize sticky material.

The key point of cutting PP pellets is adjustment of cutter, but it is not easy to achieve.

With special designed universal-joint cutter, it can help to avoid the fault from manually adjustment of cutter. Compare with strand pelletizing system, the customer was surprised and satisfied that final product looks more uniform. Furthermore, not only the capacity is raised to 700kg/hr but also saved labor cost.

KRIEGER-Z-125i / Cutter Compactor Plastic Recycling Machine / PE Foam / Korea

KRIEGER-Z-125i

After the systematic and careful production, seven days for sending and four days for installation. Finally, KRIEGER-Z-125i have been installed successfully in Daegu, South Korea

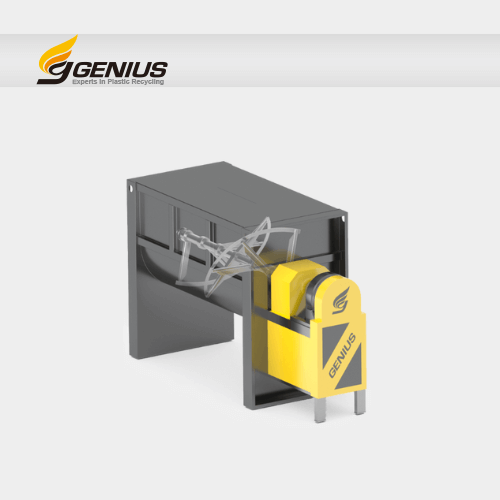

The new model of the two-stage extruder: type Z

We had seen the extruder with two stages in the past. During propelling the material from the main extruder to the sub extruder, if the rotation and speed aren’t in sync, it gets stuck in the hopper. It sometimes causes the overflow of material.

Moreover, all the material got stuck in the open type hopper. It discharged the gas and bad smell-burnt plastic smell.

In this new brand of an extruder with two stages: Z type, the main extruder and sub extruder are jointed. Therefore, it prevents the materials get stuck. Moreover, the gas/smoke that it releases is little. No MORE POLLUTION.

The set reserves efficiently space and labor force. ONLY NEEDS 2 or3 Workers to operate the whole machine/plant.

Now the machine is operating in South Korea, and it is processing PE foam and has a capacity of 400 kg per hour.

KRIEGER-100 / Cutter Compactor Plastic Recycling Machine / PE Film / Vietnam

This client is regarded as the biggest plastic bag making company in Southeast Asia which has five divisions and the place is around 300 hectare. The production line has 400 blow film machines running synchronously and the main product is LDPE plastic bag.

After KRIEGER’s installment in Vietnam, the daily productivity is around 13 tons equal to more than 500 KG per hour.

The Vietnamese client says: KRIEGER can process our redundant material to re-pelletize and the quality of pellets is excellent which can be used for the purpose of blow film. The advantages are saving costs, automatic design, and labor-saving. We just need to assign two people to take care of the machine then it will be fine.

The client placed a repeated order for the same machine due to KRIEGER’s extraordinary performance. The second machine installed in Vietnam on the estimated date of May, 2017.