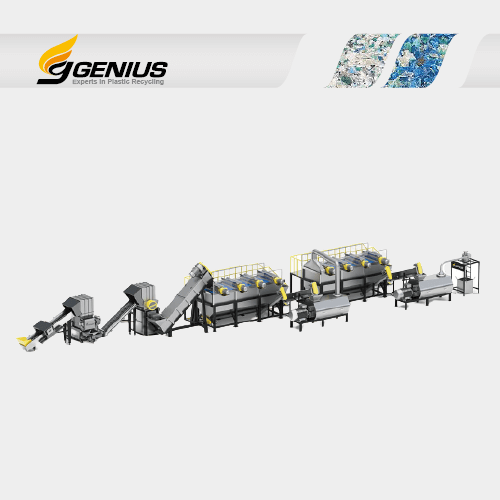

Classification : Plastic Recycling Machine

Country: Taiwan

Phone: 886-4-2630-1621

Fax: 886-4-2630-1716

Contact Person: Peter Tsai

| Model |

KR-100i |

KR-125i |

KR-135i |

KR-150i |

KR-175i |

|

| Main extruder | Screw | Φ100 mm | Φ125 mm | Φ135 mm | Φ150 mm | Φ175 mm |

| Drive |

125HP (94KW) |

175HP |

200HP (150KW) |

250HP (188KW) |

300HP (225KW) |

|

| Sub extruder | Screw | Φ125 mm | Φ155 mm | Φ155 mm | Φ165 mm | Φ200 mm |

| Drive |

40HP (30KW) |

75HP |

100HP (75KW) |

100HP (75KW) |

150HP (113KW) |

|

| Compactor drive |

75HP (56KW) |

100HP (75KW) |

125HP (94KW) |

150HP (113KW) |

175HP (131KW) |

|

| Output (kg / hr) | 300 ~ 400 ↑ | 450 ~ 600 ↑ | 650 ~ 850 ↑ | 700 ~ 800 ↑ | 900 ~ 1100 ↑ | |

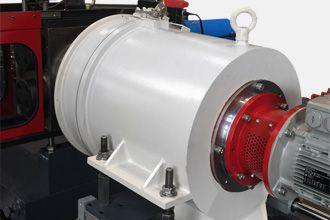

Compacting & feeding

The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity.

Multiple Cooling

Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

Unrivaled Degassing

Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency.

Exhaust-Free Construct

The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke.

Better Flexibility

The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity.

Multiple Cooling

Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

Unrivaled Degassing

Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency.

Exhaust-Free Construct

The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke.

Better Flexibility

Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant.

Cost Saving

Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant.

-

Durability

The screw is made of wear resistance materials ensuring the longevity of product life. -

Energy Saving

German compact motor gear saves energy up to 20%. -

High value product

Finished plastic pellets must be of uniform size. The pellets with high quality are more favorable for reusing in all kinds of extruders and injectors. -

Space Saving

Cutter compactor recycling machine integrates shredding, extruding and pelletizing into one machine. Without water cooling tank, the integrated recycling system takes less space. -

Efficiency Enhancement

The extruder is equipped with automatic pressure sensor. When pressure is excessive, warning light or buzzer will notify us of changing filter screen.

Genius uses dual hydraulic screen changers with dual pistons to keep the machine operating even when replacing the filter screen. It can efficiently increase overall throughput and reduce the happening of waste.

PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS and etc. Especially for plastic films, foam, woven, raffia, wash & squeezed films, flakes, materials with water content and post-consumer waste materials

|

|

|

|

Expanded Foaming Materials |

Films |

Non-Woven Fabric |

|

|

|

|

Post-consumer Bags |

Washed Films |

Washed Plastic Raffia |