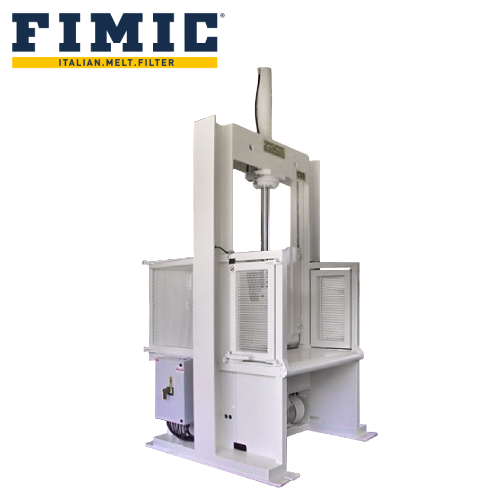

Guillotines Plastic Cutter

Categories : Rubber Cutting Machines

When FIMIC was born, our main line of production was the manufacturing of guillotines for the cutting of bales and rolls of industrial waste, and they still retain their place as our flagship produ...

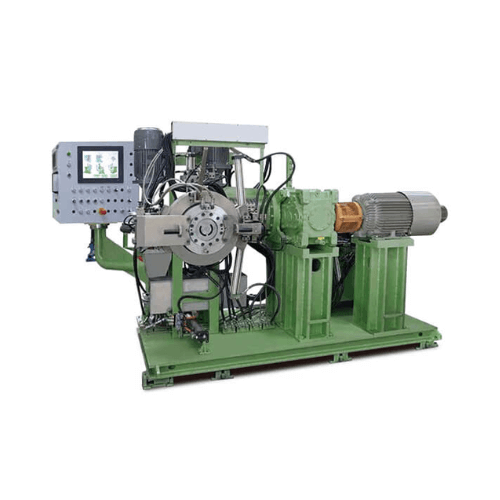

Round-Barrel Mixer CL-Z

Categories : Rubber Mixers

Suitable for many kinds of material. It is specially equipped with high speed motor & diffusion tool, which can mix material more evenly in a short time. No residual heat and no damage to the quali...

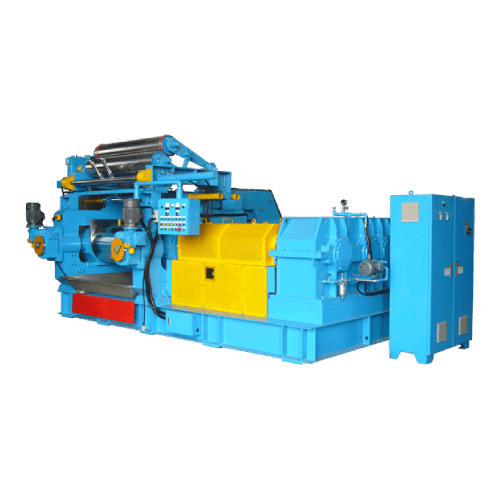

Mixing Mill / Sheeting Mill

Categories : Rubber Mixers

This machine is suitable for mixing rubber, synthetic rubber, E.V.A. or PVC and various kind chemical material or sheeting for Extruder, Calender, Hot Press or other processing machinery to make Ru...

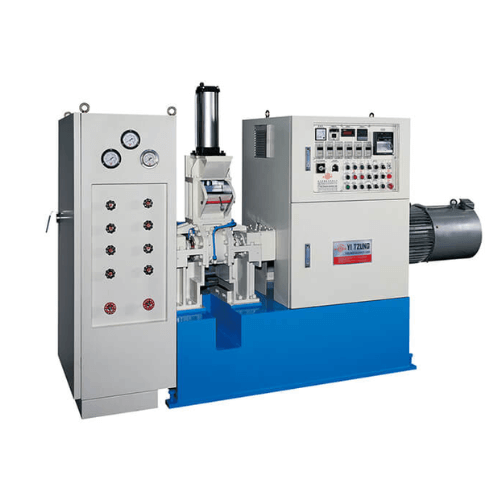

Thermosetting Injection Molding Machine (HN-U Series)

Categories : Bakelite Injection Molding Machine

It is thermosetting injection equipment, which is suitable for electrical parts, pistons, appliance handles, etc.

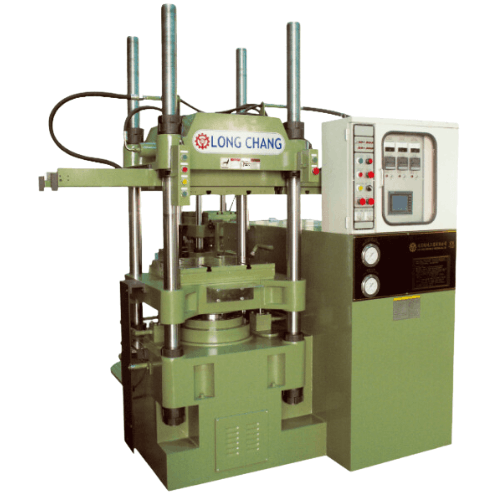

Injection Oil Hydraulic Compression Molding Machine FCT Series

Categories : Compression Molding Machines

Injection Oil Hydraulic Compression Molding Machine FCT Series

Laboratory Intensive Mixer

Categories : Dispersion Kneaders

The 1.8L Laboratory Intensive Mixer is designed for material research and develpment applications in the laboratory. The heating chamber (mixing chamber) and rotorsave built with water cir...

Rail Type Vacuum Compression Molding Machine

Categories : Compression Molding Machines

Mold plate turnover at 60°, custom design available.

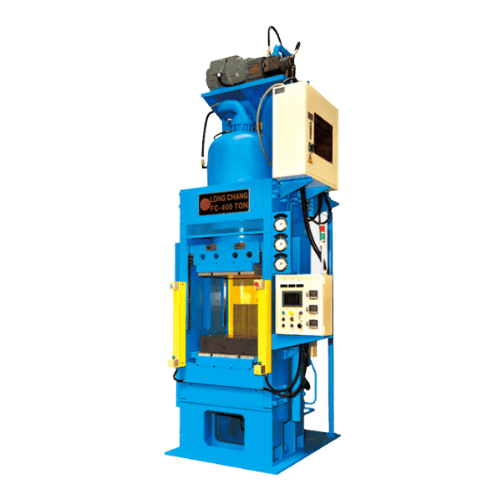

Single Body Oil Hydraulic Compression Molding Machine (Down Stroke Type) - FCT-X Series

Categories : Compression Molding Machines

APPLICATIONS: For automobile, motorcycle , truck, train any kind of butterfly and drum type of friction break lining products.

EVA Foam Tire Oil Hydraulic Compression Molding Machine - FBF Series

Categories : Compression Molding Machines

APPLICATIONS: Any kinds of EVA foam tires.

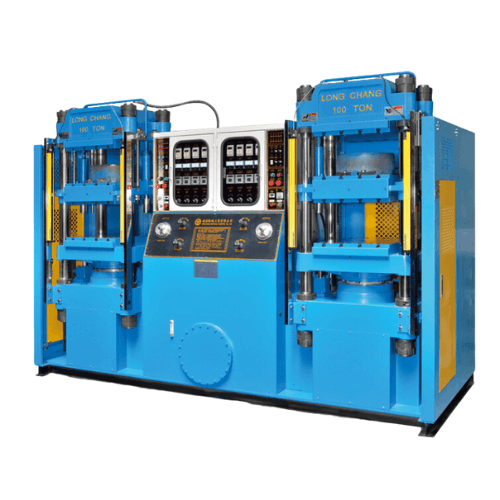

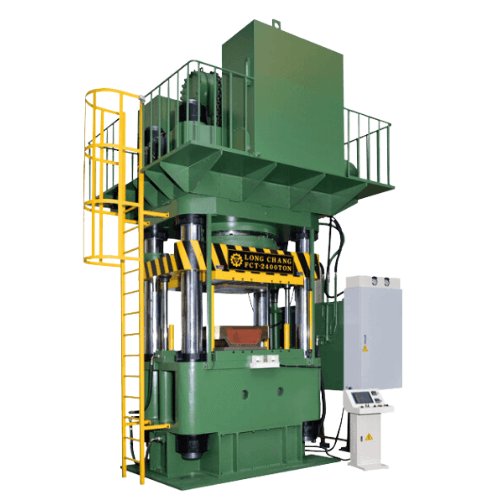

Four Columns Type Oil Hydraulic Press - FCT-L Series

Categories : Compression Molding Machines

Applications: It is suit produce magnesium components finished products, Notebook computer case, also can be formed with steel plate or stainless for making any parts such as kitchen appliance, ...

Clean Room Vacuum Rubber Compression Molding Machine

Categories : Compression Molding Machines

Specially designed for clean room to make all types of precision rubber products such as aeronautic O-rings, syringe inner pistons and so on.

Intermesh Model Dispersion Kneader

Categories : Dispersion Kneaders

Machine application various kinds of glaze, plastics and chemistry industrial mixer mixing and kneading. Occlusal fitting low low temperature mixing material. Special machinery and manufacture du...

Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine - FCE Series

Categories : Compression Molding Machines

APPLICATIONS: Suitable to be used in the molding process of double color of melamine、urea、bakelite、cup...etc.v

Multi-deck Cold / Hot Forming Machine

Categories : Compression Molding Machines

1. Capable of multi-layer production simultaneously to increase productivity and reduce the footprint and energy consumption. 2. Suitable for: rubber, composite parts, carbon fiber. 3. Multi-layer ...

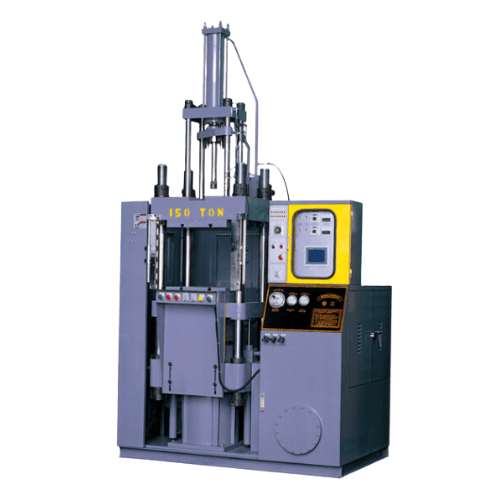

Double Decker Compression Forming Machine (Down Stroke)

Categories : Compression Molding Machines

Clamping force: 150 ton Max. surface pressure for product: 600 kg/cm2 Well mixed auto-feeding. Transparent window to check remaining material in the material barrel. Safety protection: light curtai...

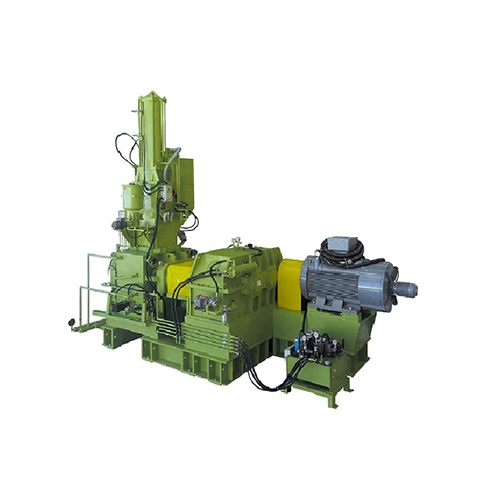

Dispersion Kneader (Hydraulic ram)

Categories : Dispersion Kneaders

This machine most suitable kneading application for all kind Rubber, Plastic and Chemical materials. This machine with following features: High quality processed products/Easy for color ...

C Type With Multi-ram Design

Categories : Rubber Curing/Vulcanizing Machines

Down stroke design with lower working height for ergonomic operating. The vulcanization press Equipped with safety catcher (optional) to prevent down stroking structure from free movement. Movable ...

Heavy Duty with Multi-ram Design Compression Molding Machine

Categories : Compression Molding Machines

Customized specification is available for molding various large dimension products.

All Electric Automation Composites Forming Machine

Categories : Compression Molding Machines

Designed with independent ceramic heating system for quick materials preheating. Equipped with heating and cooling system to meet the different forming process, the key to make TPC products with hi...

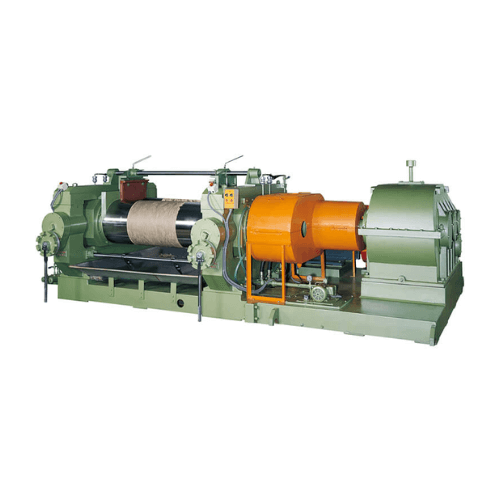

Mixing mill

Categories : Calendering Machines / Mixing Mills

Designed for mixing and kneading raw rubbers, synthetic rubbers, thermoplastics, E.V.A and chemicals, ensuring maximum uniformity of material. The processed materials are normally used on calenders...

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber:...

CE Energy efficiency Servo Press

Categories : Compression Molding Machines

CE Energy efficiency Servo Press :The servo motor system uses green electric power, which can save 80% of electricity usage, and precisely adjusts the pressure direction and position with high repe...

Rear Transfer Injection Type Rubber Compression Molding Machine

Categories : Compression Molding Machines

Special for nylon cord retread tire with high temperature or second curing for tire with low temperature. With loading and unloading platform to save labor handling.