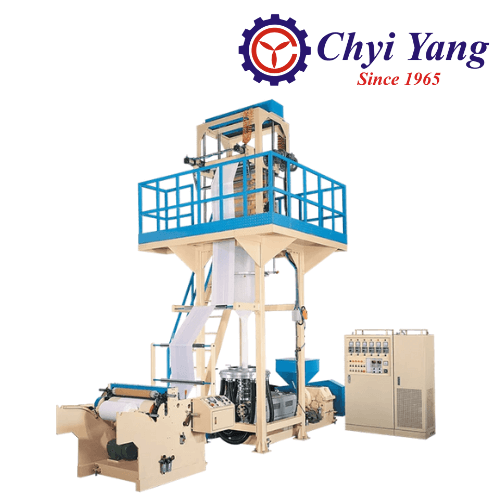

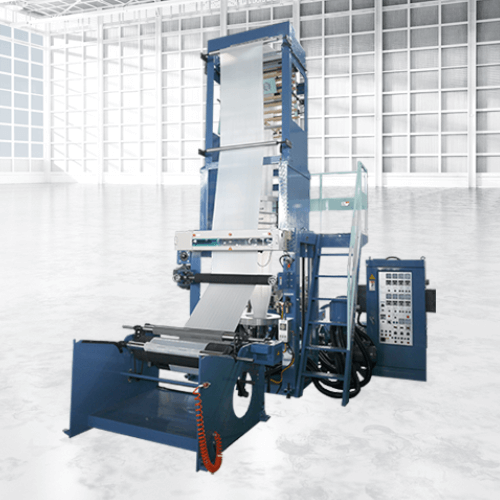

LDPE/LLDPE Blown Film Machine

Categories : Garment Bag Blown Film Machine

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and sh...

PVA Water Soluble Film Bag Machine - GF-AJ811

Categories : Garment Bag Blown Film Machine

PVA base water soluble, compostable and biodegradable eco-friendly material

Super High Speed HDPE/LDPE/LLDPE Blown Film Machine

Categories : Garment Bag Blown Film Machine

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less pla...

Blowing Film Line Making Machine

Categories : Garment Bag Blown Film Machine

The machine is applied to manufacture HDPE, LDPE, LLDPE plastic film, which is widely used in packaging film, agricultural covering film, textile packing, garment bag, shopping bag, plastic bag, ga...

GENERAL TYPE BLOWN FILM MACHINE

Categories : Garment Bag Blown Film Machine

Applicable raw materials: HDPE, LDPE, LLDPE, EVA High-efficiency machine with high capacity but low energy consumption High-class gear box with enforced lubrication system and oil cooler Well-desig...

PP BLOWN FILM MACHINE

Categories : Garment Bag Blown Film Machine

High Speed PP Blown Film Machine is suitable for producing PP bags and films. Special design of screw results in better mixing to ensure high output and good film quality. AC inverter control motor...

HEAVY-DUTY BLOWN FILM MACHINE WITH OSCILLATING HAUL-OFF UNIT

Categories : Garment Bag Blown Film Machine

Film width available from 2000 ~ 4000mm, excellent for heavy-duty bags. Unique die head and air ring design to achieve stable bubble and better even thickness film and bag. Gear box uses high torqu...