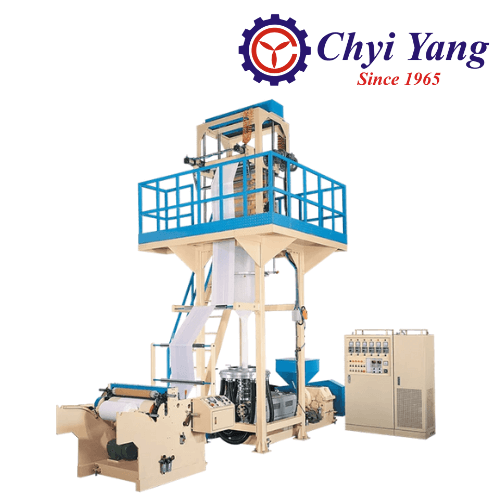

Classification : Blown Film Extrusion Machine

Country: Taiwan

Phone: 886-3-328-8686

Fax: 886-3-328-3737

Contact Person: Renee Kuo

- Barrel and Screw have special treatment and forced feeding for better output

- Easy installation & operation

- Adjusting thickness easily by screws of die, high capacity & less plastic waste

- Automatic flying cutter & manual change reels winder, flying cutter to match the

- machine speed, won’t be re-winded on the nip roller

- Main Motor is driven by inverter for better performance & less electricity

- Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film

- We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Specification

| MODEL NO. | HPE-45FH | HPE-50FH | HPE-55FH | HPE-65FH | HPE-75FH |

| Screw Diameter (mm) | 45 | 50 | 55 | 65 | 75 |

| Output (Kg/hr) * | 25-60 | 30-80 | 40-90 | 50-130 | 60-150 |

| Roller Width (mm) | 750 | 900 | 1000 | 1200 | 1500 |

| Power Required (Kw) | 27 | 35 | 42 | 52 | 65 |

| Drive Motor (HP) | 25 | 30 | 40 | 50 | 60 |

| Die Diameter (mm) | 70 & 90 | 80 & 100 | 90 & 120 | 120 & 200 | 180 & 250 |

| Machine Dimension (m) | 4.8 x 2.5 x 4.3 | 5.1 x 2.6 x 4.5 | 5.5 x 2.7 x 5.2 | 5.6 x 2.9 x 6.5 | 5.7 x 3.2 x 7.2 |

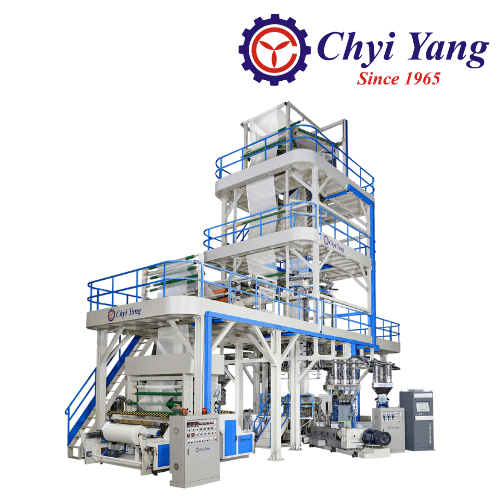

- Barrel and Screw have special treatment and forced feeding for better output

- Double lip air ring & better cooling system to support the high speed capacity

- Adjusting thickness easily by screws of die, high capacity & less plastic waste

- Automatic flying cutter & automatic change reels winder, automatic winder to match the machine speed, won’t be re-winded on the nip roller\

- Main Motor is driven by inverter for better performance & less electricity

- Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film

- We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Specification:

| MODEL NO. | HPE-45FS | HPE-50FS | HPE-55FS | HPE-65FS | HPE-75FS |

| Screw Diameter (mm) | 45 | 50 | 55 | 65 | 75 |

| Output (Kg/hr) * | 30-70 | 40-90 | 50-105 | 70-160 | 80-180 |

| Roller Width (mm) | 750 | 900 | 1000 | 1200 | 1500 |

| Power Required (Kw) | 27 | 30 | 32 | 45 | 52 |

| Drive Motor (HP) | 25 | 30 | 40 | 50 | 60 |

| Die Diameter (mm) | 70 & 90 | 80 & 100 | 90 & 120 | 120 & 200 | 180 & 250 |

| Machine Dimension (m) | 4.8 x 2.5 x 4.3 | 5.1 x 2.6 x 4.5 | 5.5 x 2.7 x 5.2 | 5.6 x 2.9 x 6.4 | 5.7 x 3.2 x 7.2 |

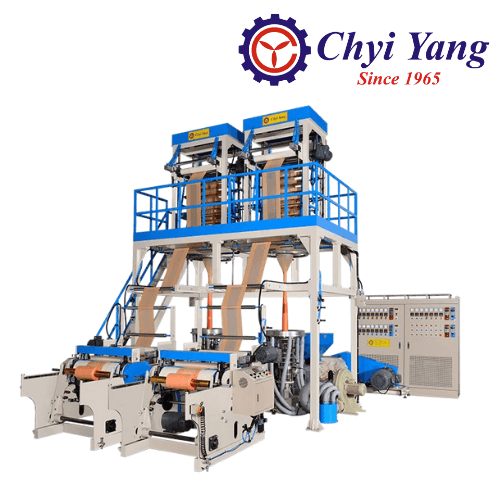

- Barrel and Screw have special treatment and forced feeding for better output

- Double lip air ring & better cooling system to support the high speed capacity

- Full automatic non-tension winder to ensure the film won’t tight the shaft

- Main motor is driven by inverter controller for better performance

- Easy installation & operation

- Adjusting thickness by die easily, high capacity & less waste plastic film

- This machine is equipped with fully automatic cut & change reel winder, front cutter type

- Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film

- We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Specification:

| MODEL NO. | HPE-45FT | HPE-50FT | HPE-55FT | HPE-65FT | HPE-75FT |

| Screw Diameter (mm) | 45 | 50 | 55 | 65 | 75 |

| Output (Kg/hr) * | 30-70 | 40-90 | 50-105 | 70-160 | 80-180 |

| Roller Width (mm) | 750 | 900 | 1000 | 1200 | 1500 |

| Power Required (Kw) | 27 | 35 | 42 | 52 | 65 |

| Drive Motor (HP) | 25 | 30 | 40 | 50 | 60 |

| Die Diameter (mm) | 70 & 90 | 80 & 100 | 90 & 120 | 120 & 200 | 180 & 250 |

| Machine Dimension (m) | 4.8 x 2.5 x 4.3 | 5.1 x 2.6 x 4.5 | 5.5 x 2.7 x 5.2 | 5.6 x 2.9 x 6.4 | 5.7 x 3.2 x 7.2 |