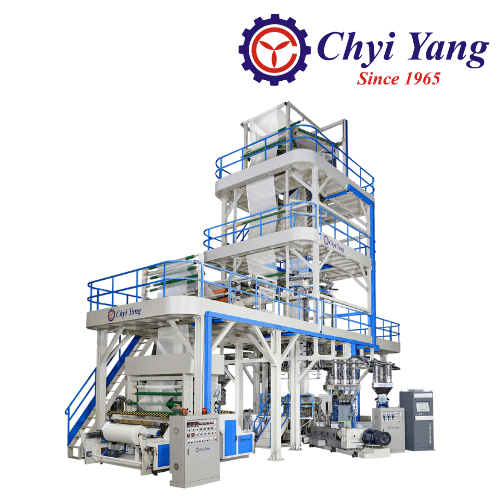

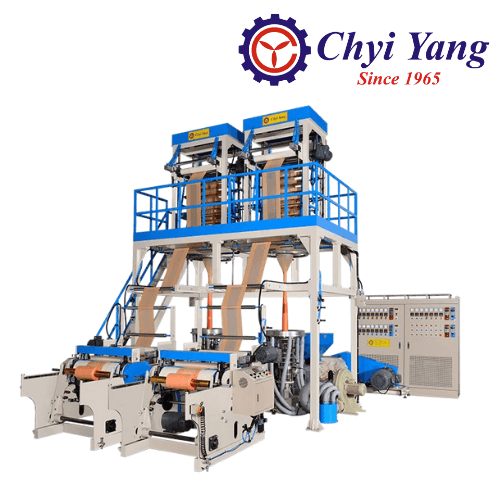

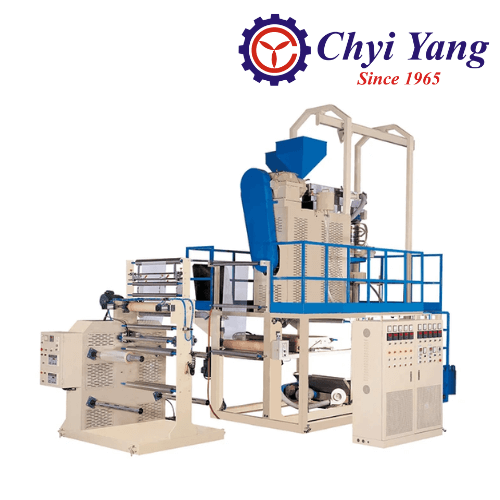

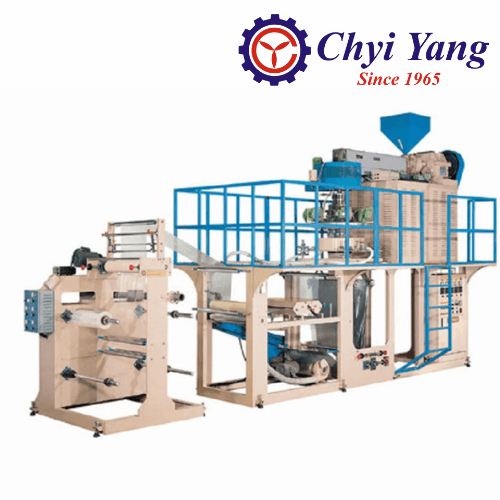

Classification : Blown Film Extrusion Machine

Country: Taiwan

Phone: 886-3-328-8686

Fax: 886-3-328-3737

Contact Person: Renee Kuo

- Under 65mm extruders are suitable for producing T-shirt bags, shopping bags, flat bags, garbage bags etc.

- 85mm & 90mm extruders can produce onion bags if customers required

- Easy installation and operation

- Precise adjustment of die to produce smooth film, more output and less waste

- Purcahsing fully automatic cut & change reel winder makes machine more automatically & saves time of operators

- Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film

- We didn’t show all our models, please don't hesitate to contact us for bigger extruders.

| MODEL NO. | HPE-35SE | HPE-45SE | HPE-55SE | HPE-65SE | HPE-75SE |

| Screw Diameter (mm) | 35 | 45 | 55 | 65 | 75 |

| Output (Kg/hr) * | 10-30 | 15-48 | 20-70 | 30-90 | 40-110 |

| Roller Width (mm) | 600 | 750 | 900 | 1200 | 1500 |

| Power Required (Kw) | 18 | 27 | 32 | 45 | 52 |

| Drive Motor (HP) | 10 | 15 | 30 | 40 | 50 |

| Die Diameter (mm) | 40 & 60 | 75 & 90 | 80 & 100 | 100 & 150 | 150 & 200 |

| Machine Dimension (m) | 3.9 x 2.3 x 4.2 | 4.2 x 2.5 x 4.5 | 4.8 x 2.7 x 4.5 | 4.9 x 2.9 x 5.2 | 4.9 x 2.9 x 6.5 |

* Output depending on film width, thickness, die size, raw material.

★ For more details specification, special requirements & quotation, please kindly contact us.