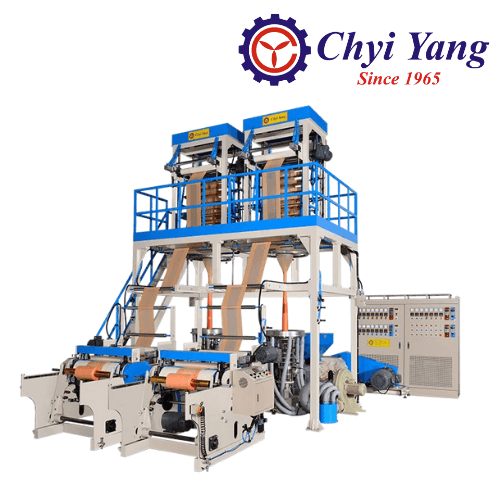

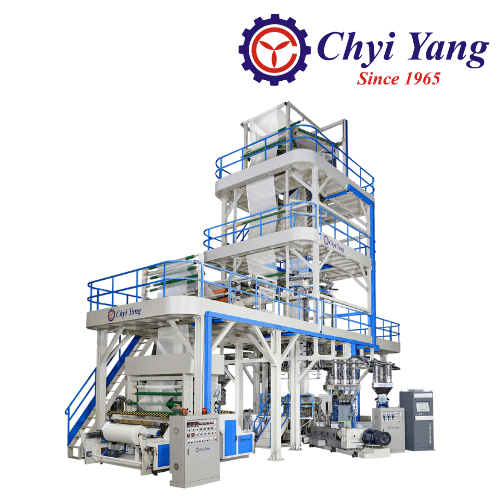

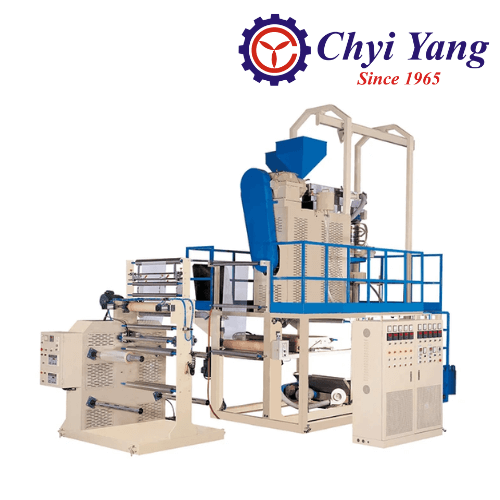

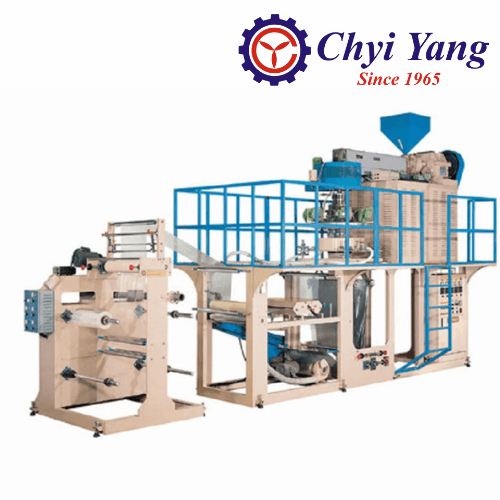

Classification : ABA/2/3/4/5/7-LAYER CO-EXTRUSION

Country: Taiwan

Phone: 886-3-328-8686

Fax: 886-3-328-3737

Contact Person: Renee Kuo

- Model ABA is equipped with two extruders to supply A+B+A die. ABA-TD series is equipped with standard screws to provide two dies. ABA-FD series is equipped with forced feeding screws to provide two dies in order to have more capacity.

- The ABA structure can be used HDPE in out-layer, and added carbonate & recycled resin in in-layer. The film will get the similar stretch & touch feeling of HDPE single layer film. The physical structure of HDPE single layer bags will be destroyed because of adding carbonate & recycled resin, but ABA bags will be totally improved in physical structure and save resin cost.

- Purchasing extra 2-layer co-extrusion die can produce normal A+B 2-layer film.

| MODEL NO. | ABA-TD35TE2 | ABA-TD45TE2 | ABA-TD55TE2 | ABA-FD45TE2 | ABA-FD55TE2 |

| Screw Diameter (mm) | 35 x 2 sets | 45 x 2 sets | 55 x 2 sets | 45 x 2 sets | 55 x 2 sets |

| Roller Width (mm) | 400 x 2 sets | 600 x 2 sets | 750 x 2 sets | 600 x 2 sets | 750 x 2 sets |

| Output * (kg/hr.) | 25-50 | 40-90 | 50-100 | 60-140 | 80-180 |

| Film Thickness (mm) | HDPE: 0.008-0.06mm | ||||

| Drive Motor (HP) | 15 x 2 set | 20 x 2 sets | 30 x 2 sets | 25 x 2 sets | 40 x 2 sets |

| Die Diameter (mm) | 40 & 65 x 2 sets | 50 & 75 x 2 sets | 80 & 100 x 2 sets | 70 & 90 x 2 sets | 90 & 120 x 2 sets |

| Heating Zone | 15 zones | 17 zones | 19 zones | 19 zones | 19 zones |

For more details specification, special requirements & quotation, please kindly contact us.

The above specifications are for reference, the correct specifications are subject to official quotation.