Industrial Lamination Machines

Industrial lamination machines bond two or more layers of materials such as plastic films, aluminum foil, paper, and nonwoven fabric using dry, wet, solvent-based, or solventless techniques. These machines support various coating and adhesive methods, making them ideal for food packaging, pharmaceutical wrappers, paper bags, textiles, and construction materials.

PRM-Taiwan features a wide range of lamination solutions including Dry Laminating Machines, Wet Laminating Machines, Dry/Wet Lamination Machines, Solvent and Solventless Laminators, Inline Coating and Lamination, and Woven Sack / Paper Lamination Machines, tailored to different materials and production needs.

Alu-Foil HSL Coating Machine (WAC Series)

Categories : Coating & Laminating Machine

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension contr...

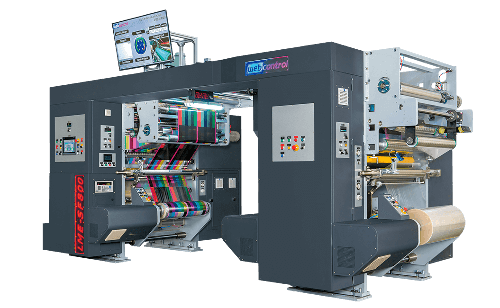

Solventless Laminating Machine LME-SF1300

Categories : Solventless Lamination Machines

- Five roller coating system - Three roller laminating system - Easy &quick cleaning coating station - Accurate adhesive width & dosing control - Closed loop tension control via dancer roller

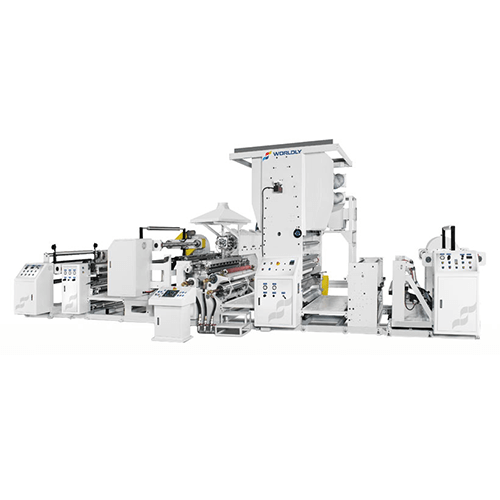

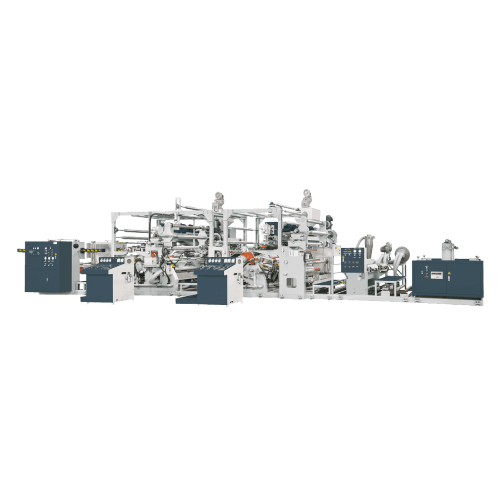

Mono Extrusion Coating & Laminating Machine (WEL Series)

Categories : Coating & Laminating Machine

Worldly extrusion coating lamination machine is well-known in the flexible converting machinery from Taiwan. To cater most of low-waste packaging market our mono extrusion coating & lamination ...

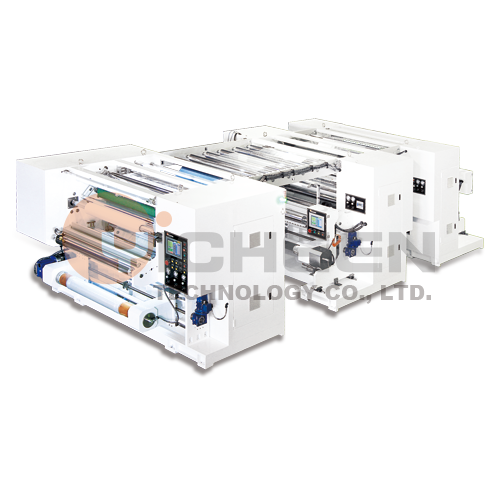

Laminating Machine

Categories : Dry / Wet Lamination Machine

Application:Optical film, Composite film material...etc yicheen

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and...

Solvent-less Laminating Machine (WSL Series)

Categories : Solventless Lamination Machines

For the solvent-free lamination, WORLDLY launches solvent-less laminating machine WSL series. The manipulation is much easier and simple with the PLC digital control system and touchable human-mach...

Solventless Laminating Machines LME-SF800/1000/1300

Categories : Solventless Lamination Machines

The solventless laminating process is using two-component adhesive. Without solvent involved, this process makes the production more eco-friendly. Precise and proportional speed control on coati...

Wet Laminating Machine - FLM-WET

Categories : Dry / Wet Lamination Machine

Wet Laminating Machine Suitable for laminating all types of paper, film, and aluminum foil, such as, cigarette box wrapping, lunch and cake boxes, and etc..

Tandem Extruder Machine (YSJ)

Categories : Woven Sack / Paper Lamination Machine

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

Triple Extruder Machine (YSJ)

Categories : Woven Sack / Paper Lamination Machine

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

Feed Block Type Co-Extrusion Coating Machine (YSJ)

Categories : Woven Sack / Paper Lamination Machine

Our extrusion coating lamination machine is designed for high precision multi-layer laminated film to provide high quality flexible packaging material and other purpose materials.

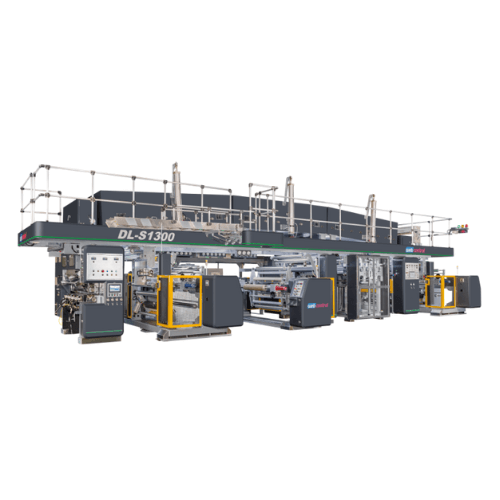

Shaftless Type Dry Laminating Machine DL- S1000/S1300

Categories : Dry / Wet Lamination Machine

Purpose of Machine: - For Plastic Laminating. - For flexible Packaging Converting.

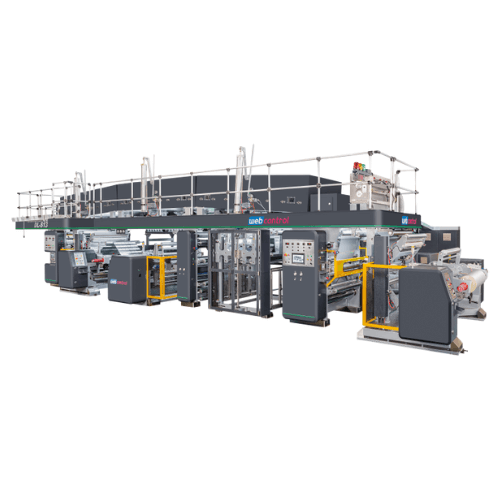

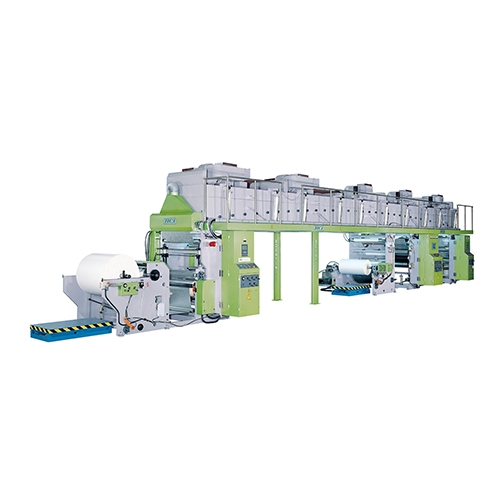

Dry Laminating Machine (WDL Series)

Categories : Dry / Wet Lamination Machine

In response to the mass demand of various materials and multiple methods in flexible packing markets, WORLDLY provides the WDL multiple functional drying laminating machineries as the ultimate solu...

Extrusion Lamination Machines FML-EXL

Categories : Solventless Lamination Machines

PLC STATION 1 - Laminating speed control - Extruding speed setting - Laminating parameter setting - Operation temperature setting - Driver status monitoring - Production additives saving - Malfunct...

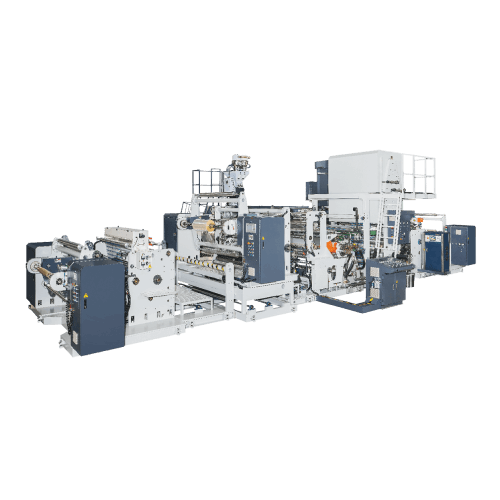

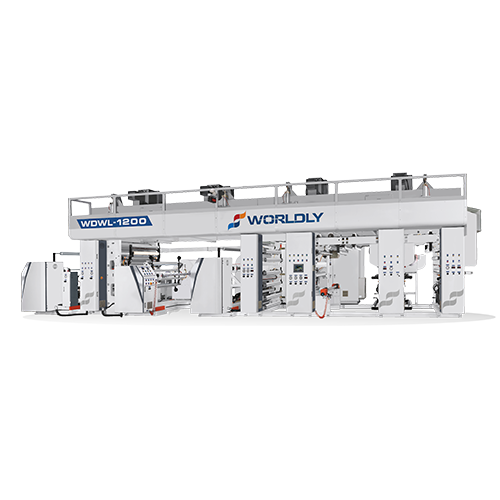

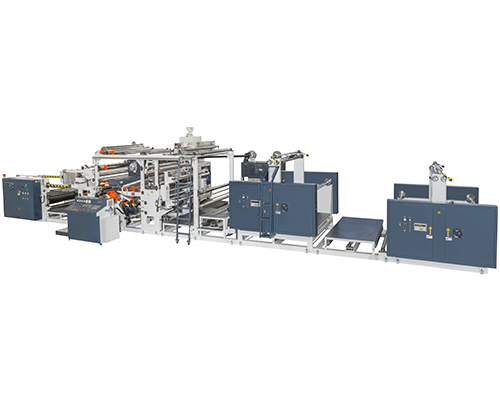

Dry / Wet Laminating Machine (WDWL Series)

Categories : Dry / Wet Lamination Machine

New model of Laminating Machine. Worldly multi-function and high efficient dry & wet laminating machine can apply to working on various materials. Especially the design of two-in-one functio...

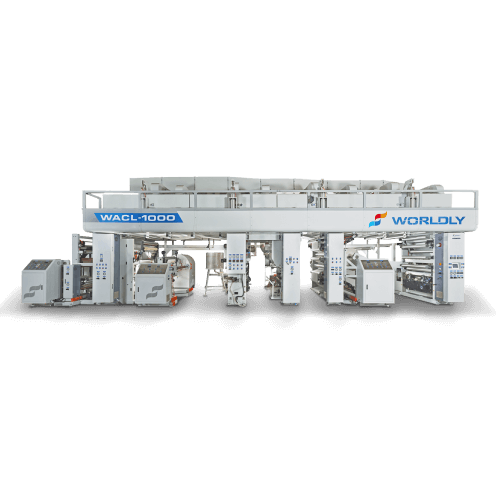

Aluminum Foil Coating & Laminating Machine (WACL Series)

Categories : Coating & Laminating Machine

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension contr...

Tandem Extrusion Lamination Machine (YSL-T)

Categories : Coating & Laminating Machine

This series of machines are available for tubular woven bag, other working materials to do double side lamination process.

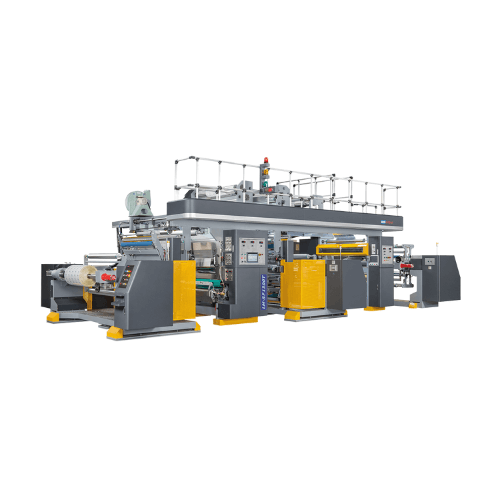

Turret Type Solventless Laminating Machine LM-SF1300T

Categories : Solventless Lamination Machines

- SHAFTLESS-INSERT TYPE BUSHING - Turret Type Shaftless Unwind & Rewind - Coating Head Consists of 5 rollers with 3 independent motor drives for doctoring roller, dosing roller sleeved transfer...

Aluminum Foil Coating Machine Tandem Type (WAC-DT Series)

Categories : Coating & Laminating Machine

For its strong characters of odor free, lightproof, antioxidant, and flavor preservation, aluminum foil has become one of the most popular solutions for soft packing industries. Laminated aluminum ...

Aluminum Foil Coating & Laminating Machine (WACL-1300)

Categories : Coating & Laminating Machine

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension contr...

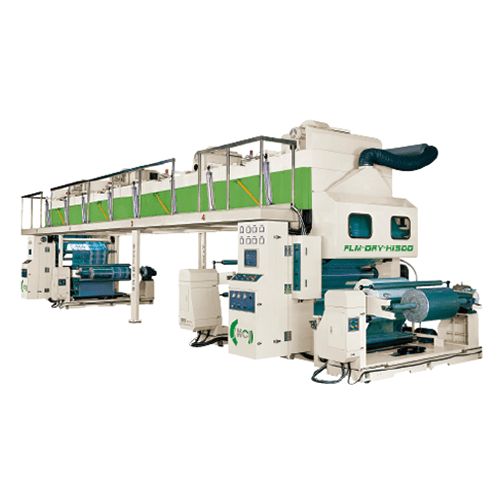

Dry Laminating Machine-FLM-DRY

Categories : Dry / Wet Lamination Machine

The FLM Dry Laminating Machine is specially designed for roll laminating operations of flexible packaging materials such as BOPP, CPP, PET, PE, Nylon, Aluminum Foil, and a variety of multi-layer fi...

Mono Extrusion Coating Machine (YSJ)

Categories : Coating & Laminating Machine

Machine is equipped with an automatic control system so the operator can control it easily. The human machine interface panel displays operational status and information. Through the control panel,...

Sandwich Extrusion Lamination Machine (YSL-U)

Categories : Woven Sack / Paper Lamination Machine

This series of machines are available for cement bag, compound materials, sandwich lamination process…etc.

Solvent-less & Solvent-base Combi Laminating Machine(WDSL Series)

Categories : Solventless Lamination Machines

For the solvent-free lamination, WORLDLY launches solvent-less & solvent-base combi laminating machine WDSL series. The unwinder and rewinder are adopted with a double shaft turret type with au...