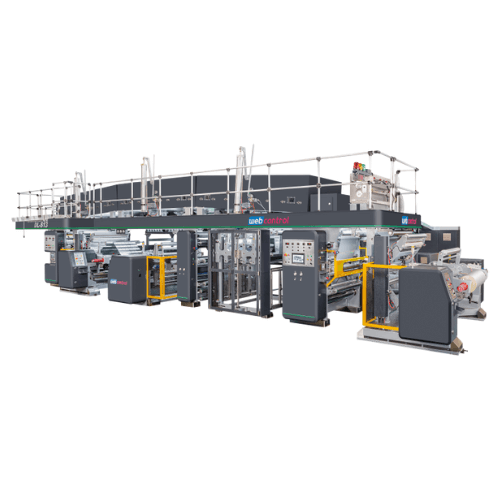

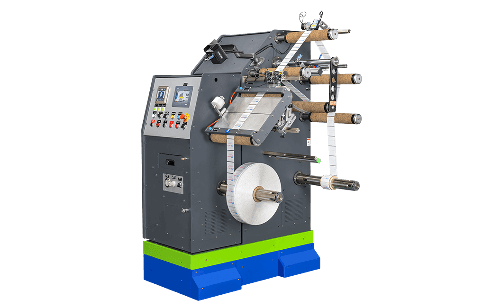

Classification : Converting Machines

Country: Taiwan

Phone: 886-4-23587272

Fax: 886-4-23580882

Contact Person: Vicky Chen

PURPOSE OF MACHINE

- This machine is for the Laminating process that using solvent-based adhesive.

- Reliable tension control with mature lamination process able to make high-end product such as retort, sterilize and medical pouches.

- The gravure coating station allows high precision and consistency on coating weight.

- Efficient drying tunnel has high performance on vaporizing solvent completely to keep the product safely.

- Various options of heating solution for drying tunnel are available.

- Energy-saving system is an option to help decreasing carbon footprint and the cost on production.

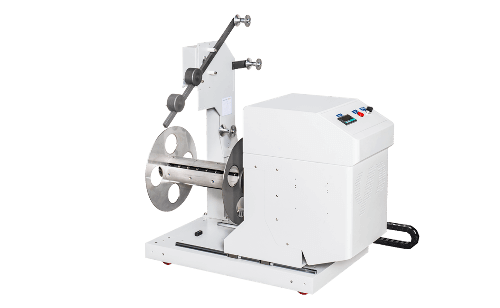

Shafted-air Shaft Type Rewinder

- Air expandable shaft, lock by pneumatic on right side.

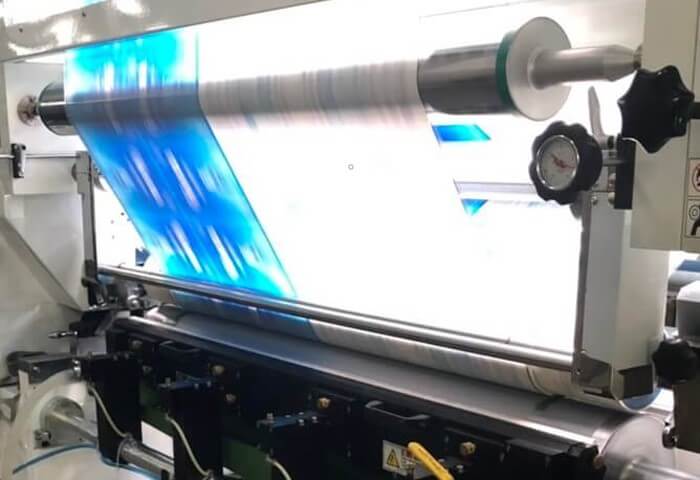

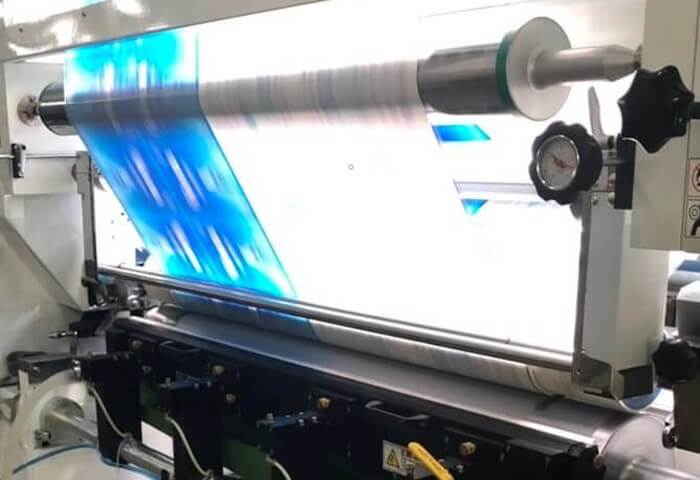

Smoothing Roll

- The smoothing roll is operated by air cylinder.

- An indexing handle provides micrometric adjustment of contact. Contact position is displayed easily.

- Smoothing roll features synchronized motion with pressure roll rising and is separated by material.

Chamber Doctor Blade System

- No glue splashing during high speed operation.

- Minimum solvent odor.

- Easy to install and clean.

- Minimum variation of liquid viscosity.

- Long service life of doctor blade.

Open Doctor Blade System

- Could be adjusted forward, backward, up, down, left and right.

Shafted-air Shaft Type Rewinder

- Air expandable shaft, lock by pneumatic on right side.

Smoothing Roll

- The smoothing roll is operated by air cylinder.

- An indexing handle provides micrometric adjustment of contact. Contact position is displayed easily.

- Smoothing roll features synchronized motion with pressure roll rising and is separated by material.

Chamber Doctor Blade System

- No glue splashing during high speed operation.

- Minimum solvent odor.

- Easy to install and clean.

- Minimum variation of liquid viscosity.

- Long service life of doctor blade.

Open Doctor Blade System

- Could be adjusted forward, backward, up, down, left and right.

Double-layer Adhesive Pan

- The outer layer is equipped with an air suction device for sucking the solvent smell, which avoids odor splashing.

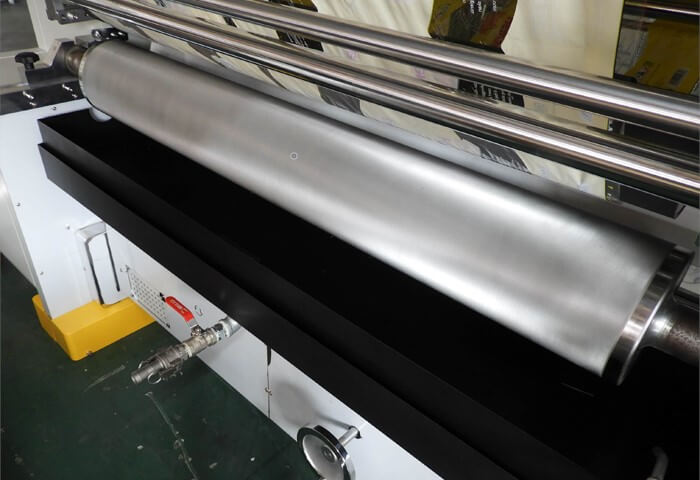

Sleeved Impression Roller

- Quick changeover

Individual Motor Drive

- The coating rubber roller and the glue-coating mesh roller are driven by individual motors which avoids uneven coating resulting from slipping between the gluing roller and the material.

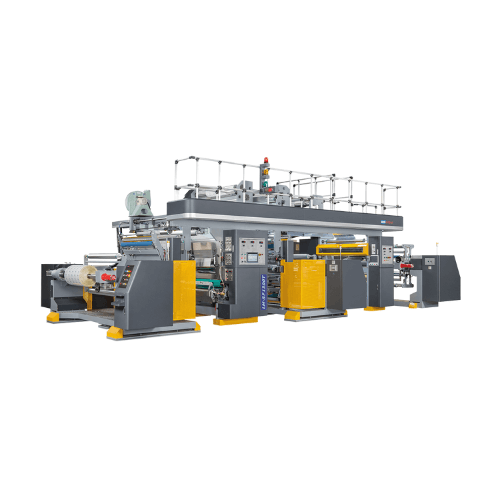

| Model | DL-1000 | DL-1300 |

| Machine speed | 200, 250 M/min | 200, 250 M/min |

|---|---|---|

| Working speed | 180 M/min | 180 M/min |

| Laminating material | All kinds of web | All kinds of web |

| Drying system | Electric heater (Gas, steam or thermal oil as optional) | Electric heater (Gas, steam or thermal oil as optional) |

| Drying tunnel length | 2.7M x3 zones (8.1M) / 3.6M x 3 zones (10.8M) | 2.7M x3 zones (8.1M) / 3.6M x 3 zones (10.8M) |

| Guide roller for drying tunnel | Ø90 mm, surface chrome plated. Driven by timing belt. | Ø90 mm, surface chrome plated. Driven by timing belt. |

| Coating system | Gravure type, individual motor drive | Gravure type, individual motor drive |

| Adhesive pan | Stainless steel double-layer type (outer layer can absorb solvent smell) | Stainless steel double-layer type (outer layer can absorb solvent smell) |

| Laminating roller | Mirror-effect treated, hot oil circulation | Mirror-effect treated, hot oil circulation |

| Drying tunnel tension range | 2-15 Kg | 2-15 Kg |

| 1st substrate tension range | 4-25 Kg | 4-25 Kg |

| 2nd substrate tension range | 3-25 Kg | 3-25 Kg |

| Finished products tension range | 4-25 Kg | 4-25 Kg |

| Max. unwind diameter | 800 mm | 800 mm |

| Max. rewind diameter | 800 mm | 800 mm |

| Unwind material fixed method | Air shaft | Air shaft |

| Rewind material fixed method | Air shaft | Air shaft |

| Preheating roller | Optional | Optional |

| Guide roller type | Ø120mm., center type, Hard chrome coating | Ø120mm., center type, Hard chrome coating |

| Ladder | Fixed type | Fixed type |

| Max. material width | 1000 mm | 1300 mm |

| Coating roller width | 1200 mm | 1400 mm |

| Coating width range | 600-1000 mm | 600-1300 mm |

| Drying blower | 5HP x 3 sets | 5HP x 3 sets |

| Exhaust blower as optional | 15HP | 15HP |

| Memory data | Optional | Optional |

| Auto. Splicing system | ● | ● |

| Upper cutter on rewinder | ● | ● |

| Lower cutter on unwinder | Optional | Optional |

| Upper cutter on unwinder 1 | ● | ● |

| Lower cutter on unwinder 1 | Optional | Optional |

| Upper cutter on unwinder 2 | Optional | Optional |

| Lower cutter on unwinder 2 | ● | ● |

| Web guide system on unwinder 1 | ● | ● |

| Web guide system on unwinder 2 | ● | ● |

| Web guide system on drying tunnel outlet | ● | ● |

| Adjustable smoothing roller | ● | ● |

| Dancing roller tension control | ● | ● |

| Chamber doctor system | Optional | Optional |

| Sleeve-type impression roller | Optional | Optional |

| Induction type laminating roller | Optional | Optional |

| Preheating roller | Optional | Optional |

| Corona treatment device | Optional | Optional |

| This is the detailed information for DL-1000/1300, Dry Laminating Machine, including model, name, description and specification. All specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice. Please contact us for further details. Related Keywords : Dry Laminating Machine, Lamination Machine, Laminator Machine, Plastic Lamination Machine, flexible Packaging Converting |

||