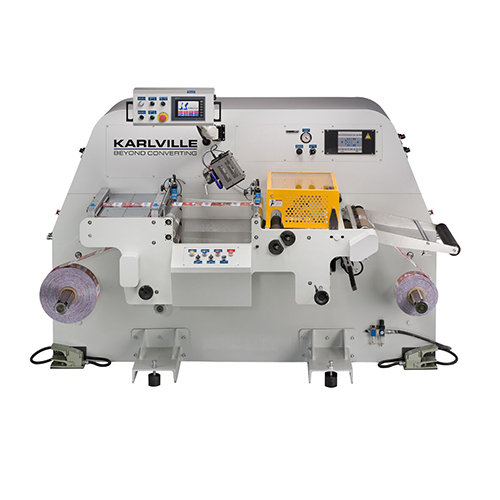

– Film Accumulation

– Unilux Strobe & Operator View Table

– Razor & Shear Knifes

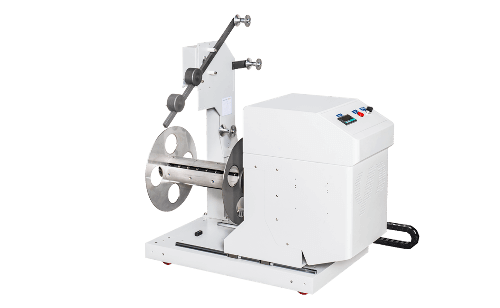

– Twin Differential Rewinds

– Digital Edge Guide

– Unwind & Splice Tables

– Foot Pedals

– Touch Screen

– Web Gripper

|

Model |

ProCombi |

|

Materials |

Unsupported film structures & self adhesive label stock |

|

Available widths |

450mm/650mm |

|

Speed |

300 meters per minute |

|

Unwind diameter |

800mm / 1000mm |

|

Rewind diameter |

600mm |

|

Core sizes |

1- 6” standard 3” (76”mm) |

|

Unwind splice table |

Standard |

|

Unwind tension system |

Auto control by load cell |

|

Unwind shaft |

Cantilever air shaft |

|

Unwind tension control |

Driven AC vector motor |

|

Unwind edge guide |

E+L Germany – ultra sonic edge; Line & edge optional |

|

Separate unwind for 1000mm diameter unwind rolls |

Optional |

|

Nip design |

Driven ac vector motor, pneumatically actuated |

|

Rewind operator view table |

Standard; synchronized strobe |

|

Rewind shafts |

Twin shaft – bi directional |

|

Rewind standard shafts |

Quick change air shaft |

|

Rewind differential shaft option |

Camlock design – width 20 & 25mm |

|

Rewind tension system |

Auto control by independent load cell for each shaft |

|

Rewind tension control |

Independent twin driven AC vector motors |

|

Lay-on roller for rewind shafts |

N Standard |

|

Web clamps for rewinds |

Standard |

|

Waste & trim removal |

Optional |

|

Splice table |

Standard |

|

Razor Slitting |

Standard – 3 knives |

|

Shear slitting |

Standard – 3 knives - cartridge |

|

Smart label counter management system – two systems available |

The LC1 smart counter uses advanced technology complemented by advanced inspection algorithms for precise label count. |

|

The LC2 smart counter uses advanced technology for precise label count, multi-lane missing label detection, matrix remains detections and automatic fault positioning/management system. |

|

|

Flag detection |

Optional |

|

Missing label sensors |

8 Channel optional |

|

Capacitive sensor |

Optional |

|

Reflective sensor |

Optional |

|

Vision system for 100% inspection separate stand for vision system installation |

.Accumulation included for fault position, fault will stop at operator viewing table. |