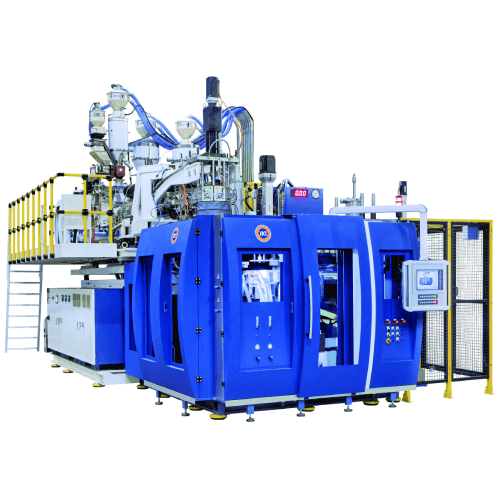

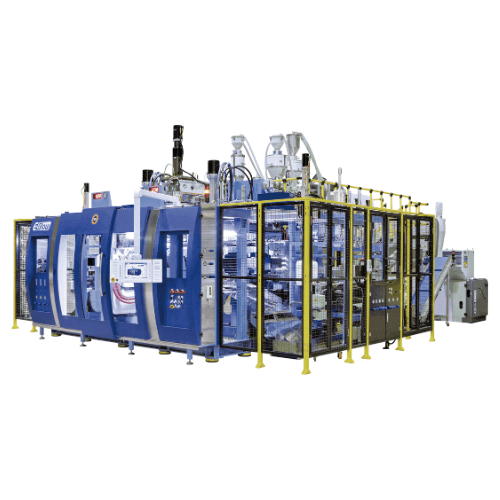

Electric Blow Molding Machines

Electric blow molding machines offer energy-efficient, clean, and precise operation for the production of plastic bottles, containers, and technical parts. These machines use servo-driven systems to reduce noise, improve repeatability, and lower maintenance costs.

PRM-Taiwan features a complete range of electric solutions including Continuous Extrusion Blow Molding Machines, Electric Stretch Blow Molding Machines, Fully Electric Blow Molding Machines, and Hybrid Blow Molding Machines—tailored for high-speed and cleanroom applications.

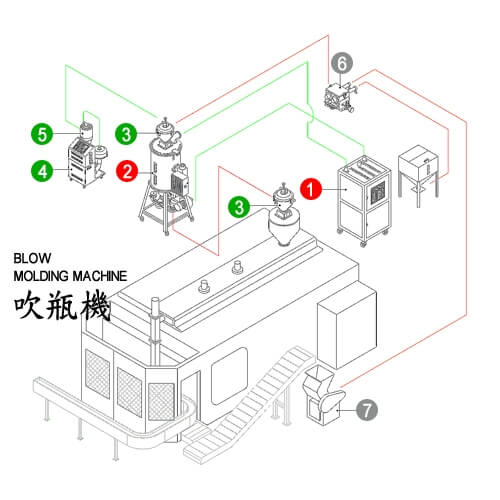

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Continuous Extrusion Blow Molding Machine

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

Continuous Extrusion Blow Molding Machine with Visi-Strip function

Categories : Continuous Extrusion Blow Molding Machine

This series is excellent for producing containers such as engine oil bottles, machine oil bottles, gasoline bottles, and similar containers. A small screw can be specially installed to indicate the...

All Electric Single Station Blow Moulding Machine For 20lt Jerry Can, 3 Layer

Categories : Continuous Extrusion Blow Molding Machine

All Electric Blow Moulding Machine with a single head single station model was exhibited. In compliance to today’s global topic for a friendly environment, low energy consumption, less plasti...

All Electric Blow Moulding Machine for 800ml Bottle with view stripe

Categories : Electric Blow Molding Machines

All Electric Blow Moulding Machine for 800ml Bottle with view stripe

Blow Moulding Machine for Jerrycan, Plastic Bottle, L-ring Drum

Categories : Continuous Extrusion Blow Molding Machine

Blow Moulding Machine for Jerrycan Plastic Bottle, L-ring Drum

Blow Molding Machine PBS-605~705 Series

Categories : Electric Stretch Blow Molding Machine

Durable and horizontal traveling mold carriage combined with German linear motion guides for maximum stability. The series is excellent for producing medium and large sized containers. Available to...

Blow Molding Machine PBS 905 Series

Categories : Continuous Extrusion Blow Molding Machine

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

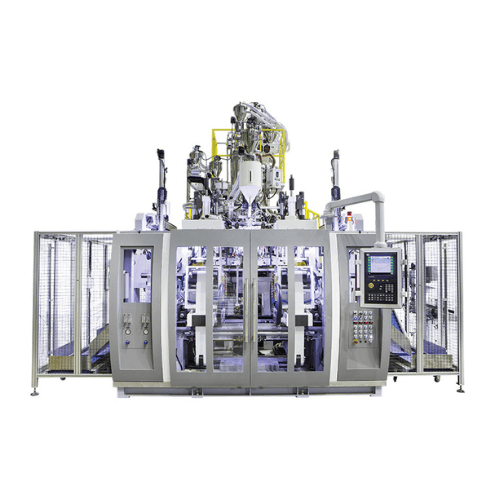

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making

Categories : Electric Stretch Blow Molding Machine

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no po...

Continuous Extrusion Blow Molding Machine for Large Containers

Categories : Continuous Extrusion Blow Molding Machine

This series is single station extrusion blow molding machine for containers from 10L to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer re...

Blow Molding Machine PBS-305~505 Series

Categories : Electric Stretch Blow Molding Machine

Custom design is avaiable to suit various plastic materials such as PE, PP, PVC, PS, PC and nylon. Designed for producing medium and small sized containers.

Continuous Extrusion Blow Molding Machine with In Mold Labeling

Categories : Continuous Extrusion Blow Molding Machine

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer...

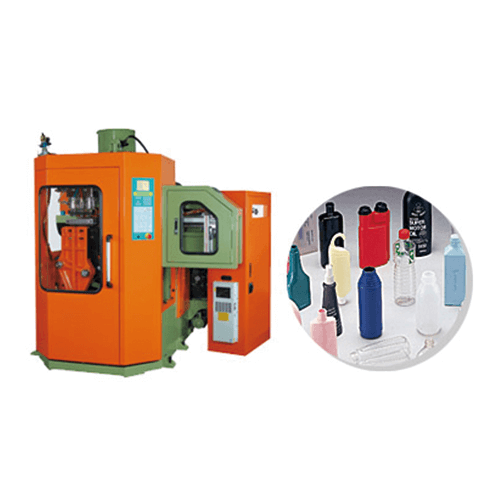

Continuous Extrusion Blow Molding Machine for Small Bottles

Categories : Continuous Extrusion Blow Molding Machine

This model is a blow molding machine for high speed production of high quality small bottles. This machine offers PLC control, and linear guide in blowing unit for shorter cycle times and much high...

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Electric Stretch Blow Molding Machine

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is ...

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot

Categories : Continuous Extrusion Blow Molding Machine

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle

Categories : Continuous Extrusion Blow Molding Machine

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle Double Head, Double Station HDPE bottle blow moulding machine

Blow Molding Machine PBSS - 905 O/1005 O

Categories : Electric Stretch Blow Molding Machine

It is designed for small containers Mouth-to-Mouth design. Mouth-to-Mouth design can improve two-time production for double-station machines. It creates a unique and new mold design and auto cuttin...

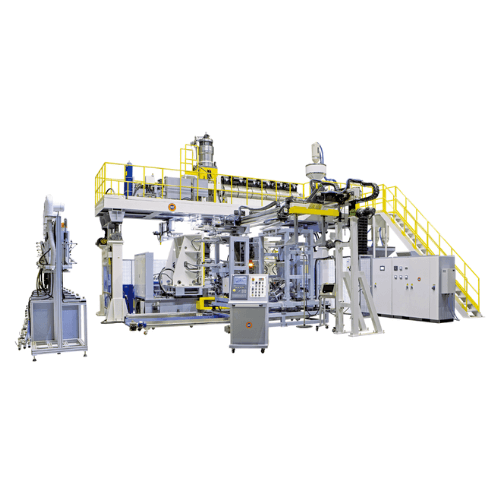

Accumulative Extrusion Blow Molding Machine for Medium to Large Containers

Categories : Continuous Extrusion Blow Molding Machine

The entire extruder can be adjusted automatically in an upward/downward direction through hydraulic power.

Success Story - PET Blow Molding Machines - Thailand

Categories : Electric Blow Molding Machines

CPSB-LSS6 high-speed blow molding machine

PET Fully Electric Stretch Blow Molding Machine

Categories : Electric Stretch Blow Molding Machine

A handle bottle makes it easier to carry and pour from a container to container. CMS series stretch blow molding machine equipped with a robot device is the choice of making bottle with handle. The...

PET Fully Electricity Stretch Blow Molding Machine for Jar and Large Containers

Categories : Electric Stretch Blow Molding Machine

-Servo-motor technology (preform transfer system – preform stretching – press clamping). -Energy savings. -Quiet. -Faster cycle times. -Reduced downtime and labor. -Optional jar preform...

Blow Molding Machine PBSS SERIES - 905 / 1005 (S / D / T / Q)

Categories : Continuous Extrusion Blow Molding Machine

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production requirement...

5 Gallon Bottles PET Fully Electric Stretch Blow Molding Machine

Categories : Electric Stretch Blow Molding Machine

CMSQ1 PET all electric stretch blow molding machines are suited for 3 gallon to 5 gallon water bottles.

PET Fully Electric & High Speed Stretch Blow Molding Machine

Categories : Electric Stretch Blow Molding Machine

12 Cavity fully automatic fully servo PET stretch blow molding machine For Bottle Volumes Less Than 600ml

Continuous Extrusion Blow Molding Machine -Double Station

Categories : Continuous Extrusion Blow Molding Machine

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer...