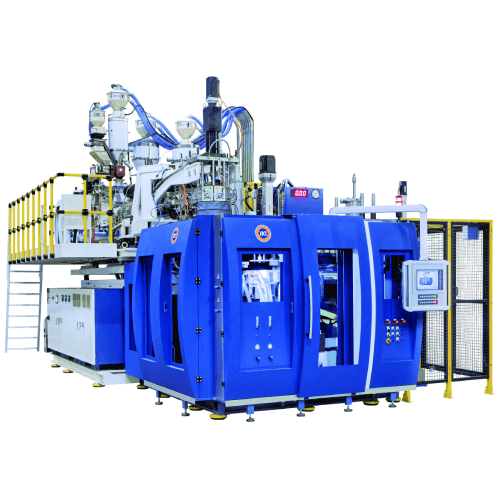

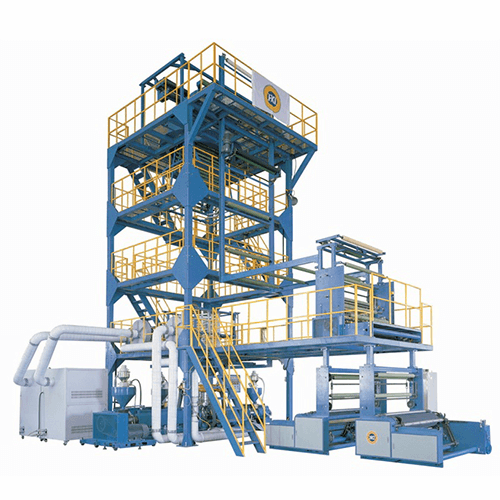

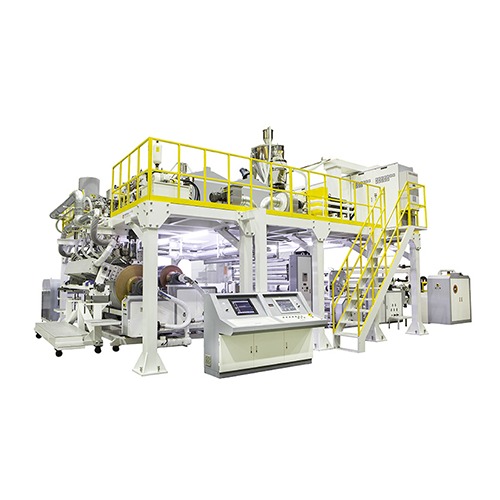

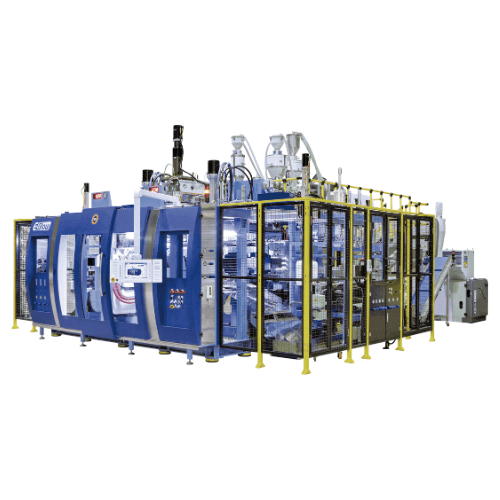

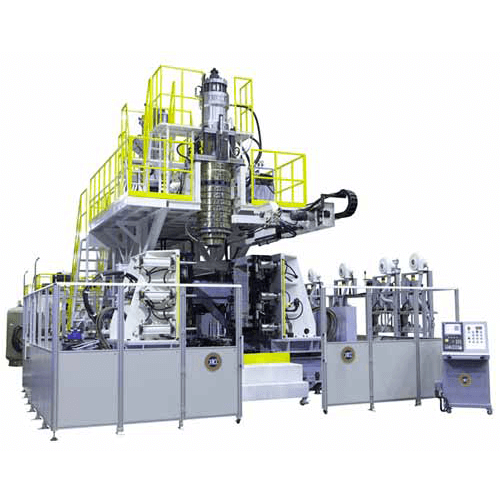

Classification : Continuous Extrusion Blow Molding Machines

Country:

Phone: 886-6-2532157

Fax: 886-6-2533079

Contact Person: Susan Wei

All Electric Blow Moulding Machine with a single head single station model was exhibited. In compliance to today's global topic for a friendly environment, low energy consumption, less plastic in use, low carbon footprint.

- Low energy consumption, less carbon footprint, no pollution, less maintenance cost 25% - 30% less energy can be saved by All Electric machine compared to traditional hydraulic one.

- Reduce, Reuse, Recycle in Plastic Capable to process more recycled grade or PCR in the middle layer of a 3 layer canister. 30% weight reduction can be achieved without compromising the quality from the drop test and stacking stability with an improved design on the shape. With 3 layer structure the use of master batch can be saves around 60-80%. The total saving of plastic in a year is tremendous. In addition, when less plastic being used per canister, with less heat, fast cooling cycle can increase the production rate.

- Industry 4.0 Smart Manufacturing control system All production data can be collected and recorded for analysis to improve the production control in many ways: * Plastic consumption in virgin grade, regrind grade, master batch

- Energy consumption data in hour/month/year, Processing condition with alarm signals Preventive maintenance instructions to keep machine always at high working efficiency.

- Entire system in use is digital communication protocol to deliver accurate readings, also by Oracle MySQL with no size limitation and use Client/Server version can link to 5 users remote at same time.

| Machine Model | FK/EHB-55/65G/55T20SS |

| Product | 20lt Jerrycan |

| Production Rate | 120bph |

| Extruder | 55/65/55mm |

| Max. Extrusion Output | 180 kg/hr |

| Head Design | 3Layer, Single Head |

| Clamp Force | 25tons |

| Platen Size | 680 x 540mm(HxW) |

20lt Jerrycan