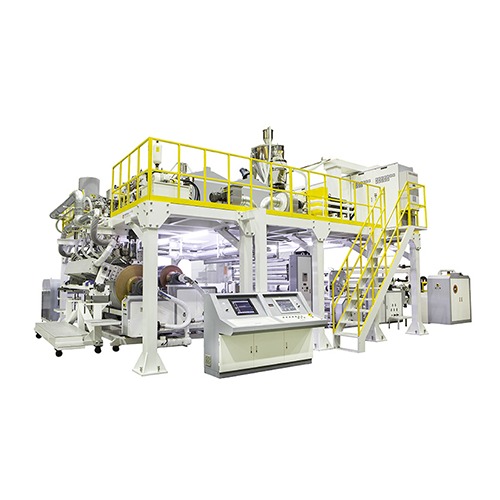

Classification : Multi-layer Co-extrusion Cast Film Machines

Country:

Phone: 886-6-2532157

Fax: 886-6-2533079

Contact Person: Susan Wei

| Resin | PP, homo-polymer & copolymer grades |

| Film width | 2200mm (max.) |

| Film thickness | 20 - 80 micron |

| Layer structure |

A layer, Co-polymer PP B layer, Homo-polymer PP C layer, Co-polymer PP |

| Line speed | 300M/Min. (Max. Mechanical design) |

| Production output | 630 KG/HR |

| Extruder A & C | 90 mm dia. Screw L/D=32:1 |

| Drive for Extruder A & C | 125 HP AC motor with vector inverter control |

| Extruder B | 125mm dia. Screw L/D=32:1 |

| Drive for Extruder B | 250 HP AC motor with vector inverter control |

| 3 layer feedblock | 1 set, EDI brand, ex USA |

| Co-extrusion Auto T-die | 1 set, EDI brand, ex USA |

| Vacuum Air Chamber | Dual Chamber design |

| Soft box | Angle & height adjustable |

| Take-off unit | 300 M/min. (Max.) |

| Oscillating unit | 1 set |

| Winder with 1000mm winding diameter | 1 set |

| Electric control panel | With air conditioner |

| PLC control system | Allen Bradley PLC system |