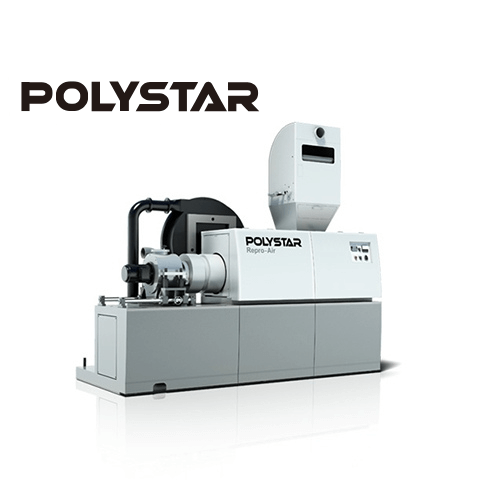

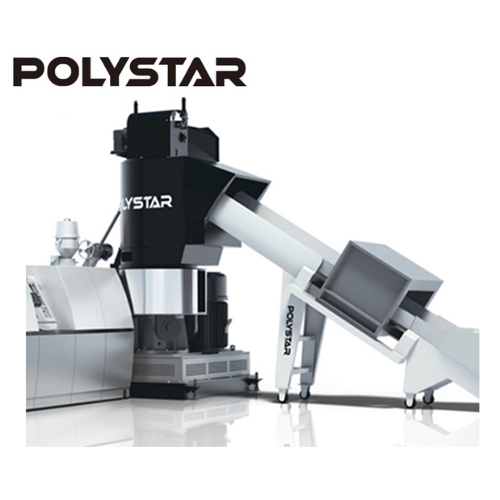

Air Cooled Plastic Recycling Machine: Repro-Air

Categories : Plastic Pellet Making Machine

● Air cooled type designed for HDPE, and LDPE in-house film waste ● Most suitable for small and mid-sized blown film manufacturers and factories to recycle their own plastic waste.

PLASTIC WOOD COMPOSITE MATERIAL PELLETIZER

Categories : Plastic Pellet Making Machine

Our Plastic Wood Composite Material Pelletizer is a state-of-the-art WPC pelletizing machine designed to deliver consistent, high-quality pellet production for wood-plastic composites. This WPC...

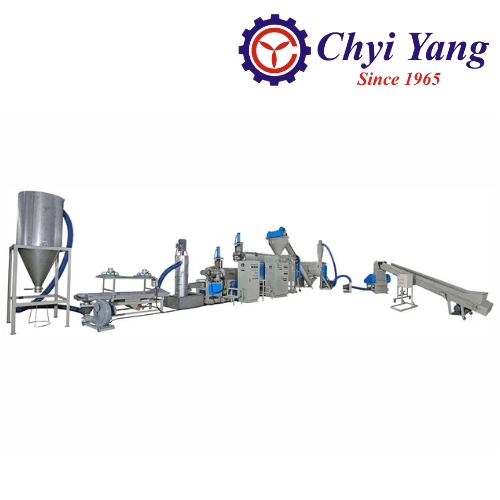

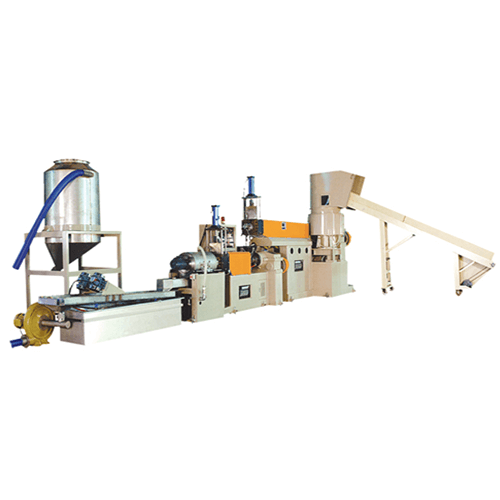

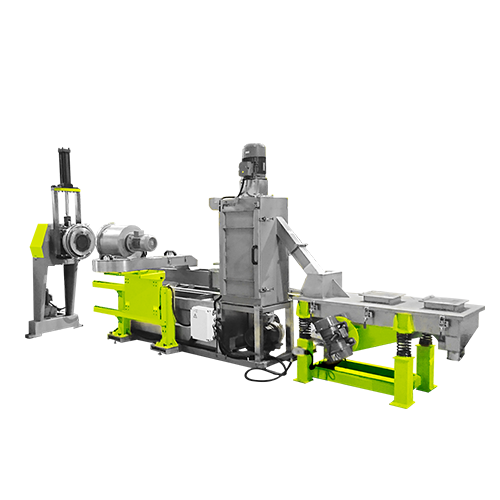

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Plastic Pellet Making Machine

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatme...

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pellet Making Machine

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force fe...

WASTE PLASTIC RECYCLING & PELLETIZING MACHINE (DIE CUT TYPE)

Categories : Plastic Pellet Making Machine

Pelletizing Machine Available for PE material Simple operation & high capacity Plastic Recycling machine Application for HDPE, LDPE, LLDPE The motor & screw length ratio ...

HF-FTO 3 In 1 Series:3 in 1 Pelletizing Extrusion / Extruder Pelletizer

Categories : Plastic Pellet Making Machine

Produced by experienced plastic recycling extruder machine manufacturer. Suitable for handling differences of materials. Suitable for processing most of the thermoplastic materials. Applicable mate...

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pellet Making Machine

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. ...

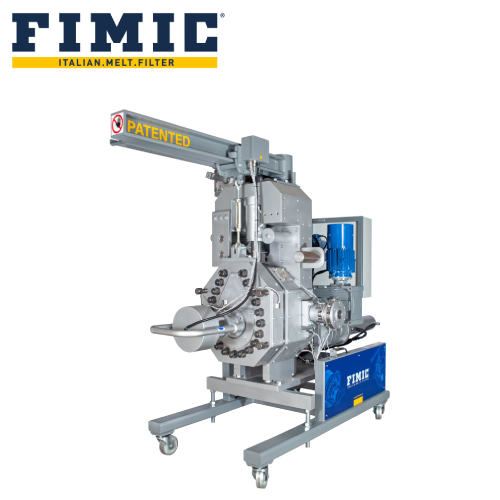

Automatic Melt Filter - RAS+REF

Categories : Plastic Pellet Making Machine

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in sc...

Two Stage Recycling Machine: Repro-FlexPlus

Categories : Plastic Pellet Making Machine

Two Stage Recycling Machine with integrated cutter compactor. Improved degassing and filtration.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pellet Making Machine

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for ...

Recycling Machine - Film, Raffia, Regrind (PE/PP): Repro-Flex

Categories : Plastic Pellet Making Machine

● High efficiency recycling line for post-industrial packaging film ● With cutter compactor integrated which eliminates the need to pre-cut material

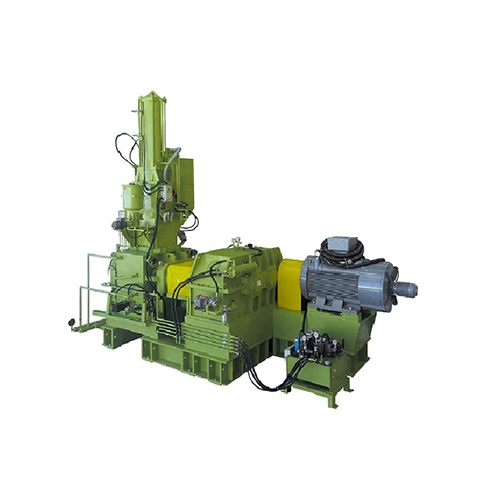

Intensive Mixer

Categories : Plastic Pellet Making Machine

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber:...

HF-TS SERIES: Plastic Pellet Extruder ( Twin Screw )

Categories : Plastic Pellet Making Machine

This pelletizing equipment (Twin screw pelletizing extrusion) is mainly applied to the thermal polymer compounding field, and we offer customized compounding solutions for any requests. We supply t...

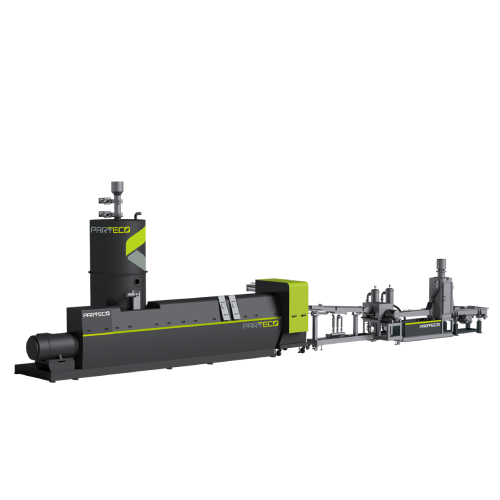

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pellet Making Machine

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly ...

Three In One Cooling Pelletizing Machine

Categories : Plastic Pellet Making Machine

Three In One Cooling Pelletizing Machine

Granulating System: Underwater Pelletizer

Categories : Plastic Pellet Making Machine

Underwater pelletizer with advanced water cooling technology. Energy saving, Easy Operation Underwater Pelletizing System. Mainly used for plastic materials such as PP、TPU、TPR、TPE etc.

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Pellet Making Machine

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

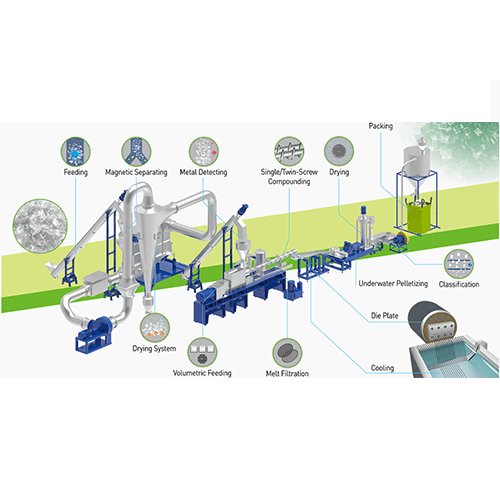

Pelletizing & Recycling System

Categories : Plastic Pellet Making Machine

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

AUTOMATIC MELT FILTER- TEN

Categories : Plastic Pellet Making Machine

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the req...

Granulating System: Water Ring Pelletizer System

Categories : Plastic Pellet Making Machine

Structure and function of our plastic water ring pelletizer system and machine. Features and advantages of our plastic water ring pelletizing machine line. Applicable plastic materials of our plast...

Water Cooling Pelletizer Line (Vertical Force Type)

Categories : Plastic Pellet Making Machine

WATER COOLING PELLETIZER LINE(VERTICAL FORCE TYPE)

3 IN 1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pellet Making Machine

INTEGRATES SHREDDING, EXTRUDING AND PELLETIZING INTO, Smash and mix well, heat, dry

Twin-Cone High Speed Pelletizing Machine-Underwater Cutting

Categories : Plastic Pellet Making Machine

Suitable for high viscosity raw materials, such as PP, PMMA, TPU, PU, PLA, PET, TPU, PU, PLA and etc. High viscosity raw material. High Capacity, Low electricity usage, Easy to clean and chang...