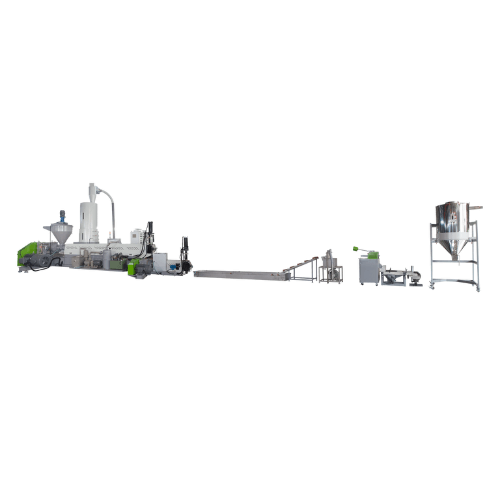

Big material storage barrel sustains stability during material input.

- User-friendly machine enables to reach high productivity standards.

- Feeding production is more stable than traditional force feeding.

- Able to open a input hole on top of barrel to conduct feeding formula and master batch pellets. It's a useful and productive type.

- Crusher is optional.

- With forced feeding hopper allows the machine to input two kind of material.

|

Model |

GD-85SE-2SP |

GD-100SE-2SP |

GD-120SE-2SP |

GD-150SE-2SP |

GD-175SE-2SP |

|

|

Main Extruder |

||||||

|

Screw Diameter L/D Ratio |

32 |

36 |

36 |

36 |

36 |

|

|

Main Power |

40~60HP |

50~100HP |

100~150HP |

150~200HP |

200~300HP |

|

|

Temp. Control |

5 zones |

7 zones |

8 zones |

9 zones |

10 zones |

|

|

Heating Capacity |

36KW |

42KW |

75KW |

90KW |

125KW |

|

|

Side Entrance Power |

5HP |

10HP |

10HP |

15HP |

15HP |

|

|

Storage Barrel Capacity |

1500L |

2500L |

2500L |

2500L |

2500L |

|

|

Storage Barrel Power |

5HP |

5HP |

5HP |

7.5HP |

10HP |

|

|

Hydraulic Power |

3HP |

5HP |

5HP |

7.5HP |

7.5HP |

|

|

Max. Outpou/Hr |

120~180kg |

200~300kg |

300~400kg |

400~650kg |

600~800kg |

|

|

Sub-extruder |

||||||

|

Screw Diameter L/D Ratio |

8 |

8 |

8 |

8 |

8 |

|

|

Power |

15HP |

30HP |

40HP |

50HP |

60HP |

|

|

Temp. Control |

3 zones |

4 zones |

4 zones |

5 zones |

6 zones |

|

|

Heating Capacity |

19KW |

22KW |

25KW |

38KW |

58KW |

|

|

Cooling tunnel |

||||||

|

Size(mm) |

3050*280*250 |

3050*280*250 |

3050*280*250 |

5000*500*280 |

5000*500*280 |

|

|

Pellet cutter |

||||||

|

Power |

3HP |

5HP |

7.5HP |

10HP |

10HP |

|

|

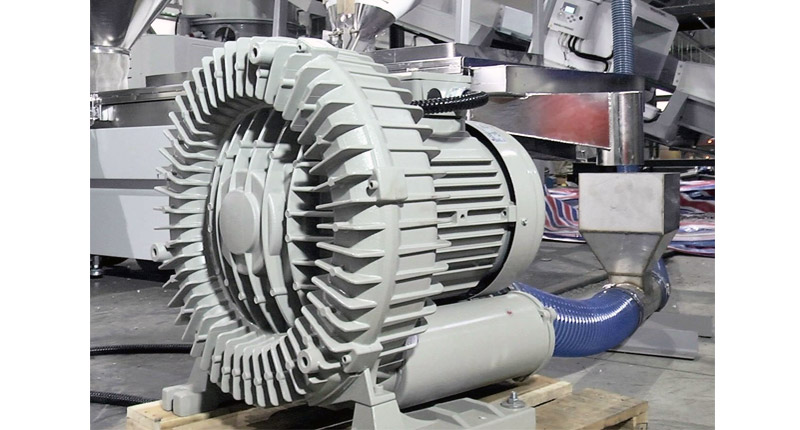

Blower |

||||||

|

Power |

3HP |

5HP |

5HP |

7.5HP |

10HP |

|

|

Storage Barrel |

||||||

|

Capacity |

1000L |

1000L |

1000L |

1000L |

1000L |

|

*Equipment specifications are also constanly updated. You are welcomed to contact us for details.

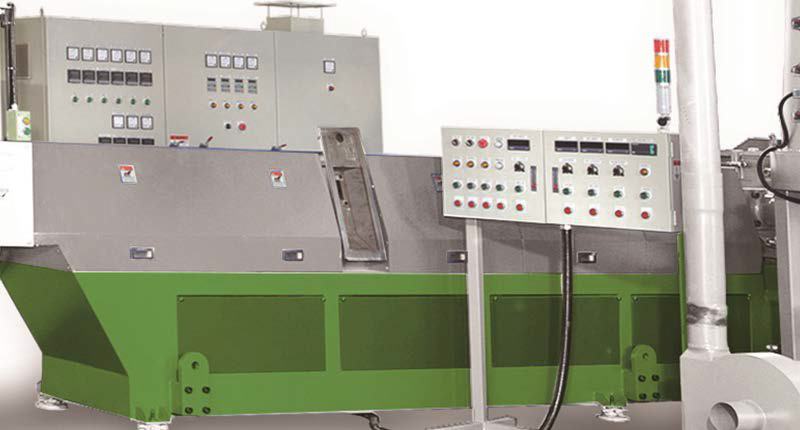

Side feeding barrel is better for storage and steady material input at same time.

Main Extruder can extrude the material whose moisture below 7%.

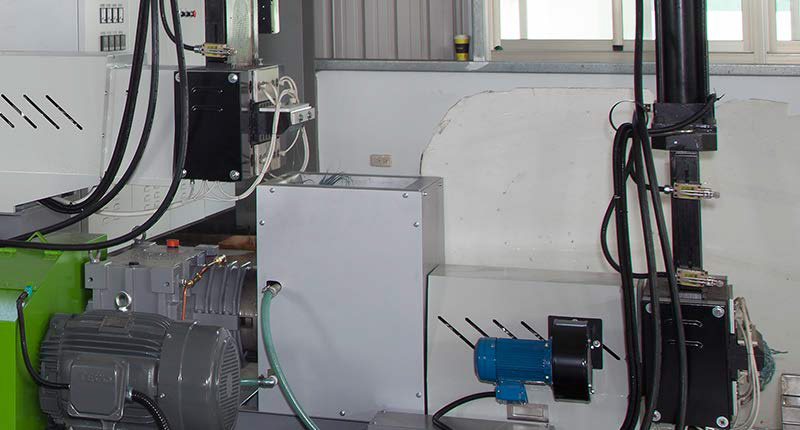

Sub extruder conducts second time filtering and ventilating for dirtier materials.

User-friendly spaghetti cutting system is suitable for high melting index material.

Blower with noiseless design.

Venting hole for main extruder provides best ventilation.

With forced feeding hopper allows the machine to input two kind of material.

PP, BOPP, OPP

Crushed PP woven bag

PP Woven Bag