MIB 85-C Handled PC Water Bottle Special Machine

Categories : Injection Stretch Blow Molding Machines

It is a handled PC water bottle, and it only needs one machine to finish the process of injection and blowing. It is an integrated, one-step, and multi-function machine. Handle and bottle belong to...

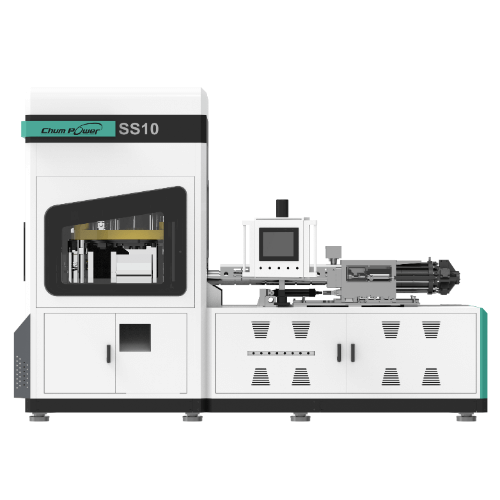

One Stage Injection Stretch Blow Molding Machine - SS10

Categories : Injection Stretch Blow Molding Machines

One-stop production machine. Specially designed and developed for small volume diversified production and special bottle designs. Finished products with glossy, complete, and untarnished appearance...

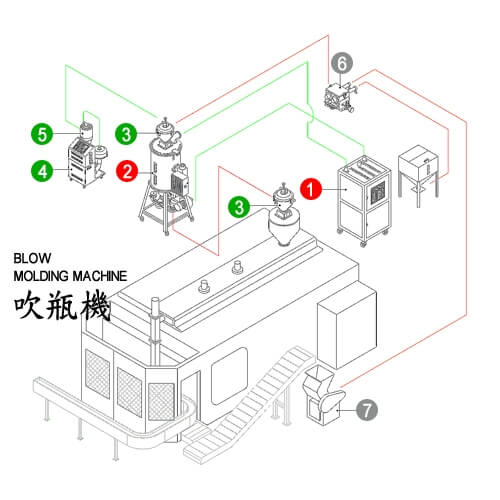

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Injection Stretch Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

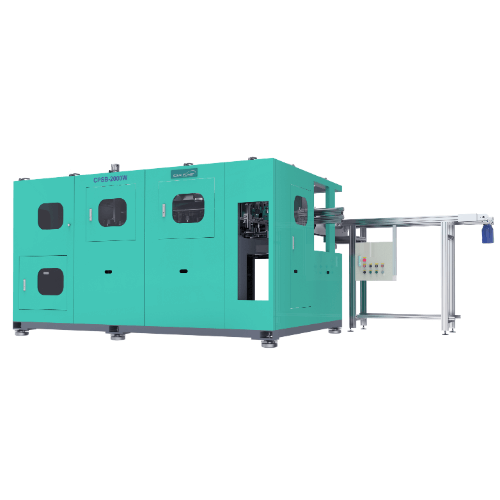

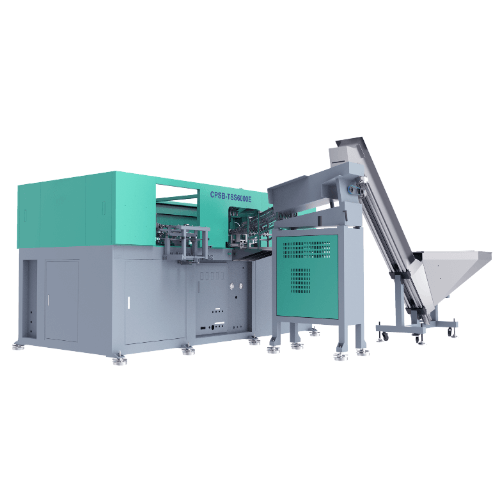

Large Volume PET Blow Molding Machine-W/L Series

Categories : Injection Stretch Blow Molding Machines

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structu...

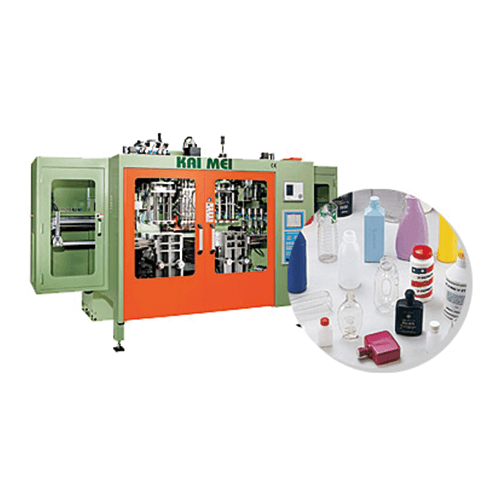

Stretch Blow Molding Machine MIB-SERIES

Categories : Injection Stretch Blow Molding Machines

This model of one-stage, three station in ection stretch blow molding machine is made by KAI MEI plastic machinery co. Itd. It has the possibility to economically produce high quality contain ...

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Stretch Blow Molding Machines

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-p...

PET Stretch Blow Molding Machine-Phoenix Series

Categories : Injection Stretch Blow Molding Machines

PET Stretch Blow Molding Machine-Phoenix Series Reliable and cost effective

Single-Stage Injection Stretch Blow Molding Machine - ISB Series

Categories : Injection Stretch Blow Molding Machines

GF/ISB series adopts the world's most advanced single-stage injection stretch blow molding machine technology. One single machine is able to achieve high quality and efficient productivity. Com...

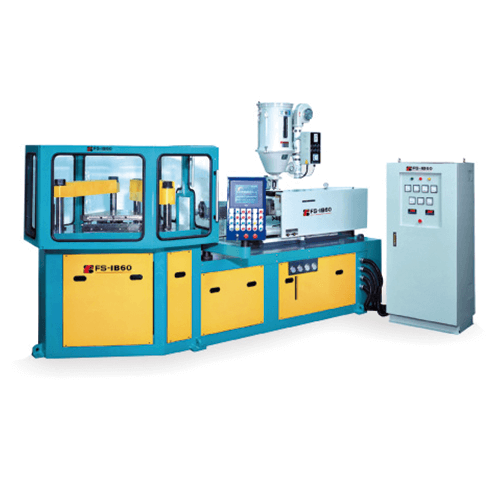

One Step Injection Blow Molding Machine-FS-IB60

Categories : Injection Stretch Blow Molding Machines

Full Shine's Injection Blow Molding Machine is the advanced machine, combining injection molding mechanism with blow molding mechanism together. This machine is suitable for processing PP, PE, ...

PET/PC One Stage Injection Blow Molding Machine FS-BT

Categories : Injection Stretch Blow Molding Machines

FS-BT-S is equipped with 2-station servo table and side-blow system. After preform injection, the servo table rotates 180 degrees, a servo screw then transfers a neck plate with PETIPC preforms to ...

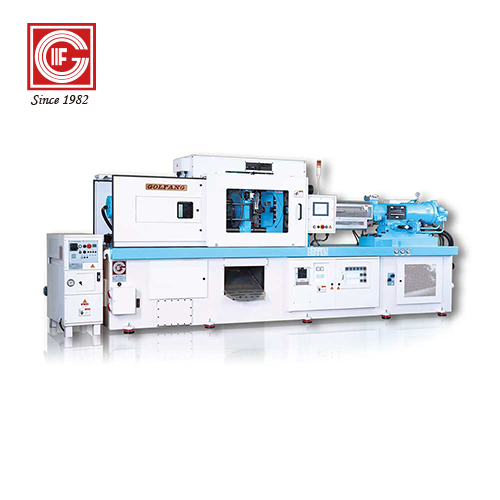

Single-Stage Injection Blow Molding Machine - IB Series

Categories : Injection Stretch Blow Molding Machines

Advanced Single Stage Blow Molding Machine Commonly used in the production of pet bottle, the mechanical design of Golfang Single Stage Blow Molding Machine is based on the blueprint of the world&#...

Semi-auto Stretching Blow Molding Machine

Categories : Injection Stretch Blow Molding Machines

Semi-Auto Stretching - Blow Molding Machine The semi-auto reheat stretch blow molding machine includes a rotary heater and blowing unit for a 2-step process: The rotary heater unit for softeni...