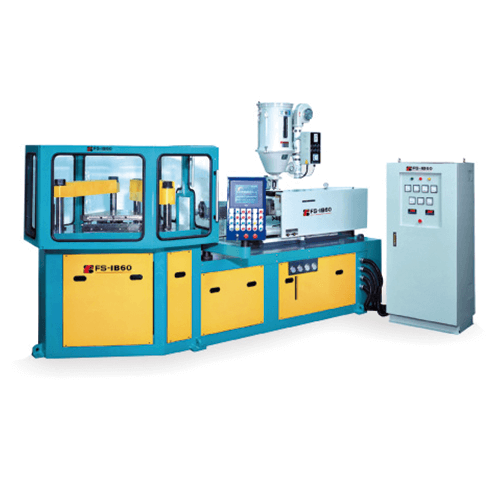

Classification : One Step Injection Blow Molding Machine

Country: Taiwan

Phone: 886-4-22765071

Fax: 886-4-22765070

Contact Person: Ms. Huang

Full Shine's Injection Blow Molding Machine is the advanced machine, combining injection molding mechanism with blow molding mechanism together.

This machine is suitable for processing PP, PE, PC, PS, PETG, & PMMA resins.

- Vertical / Front View | Flowchart

- High-Speed and Precise Quality, Suitable For Processing PP, PE, PC, PS Materials.

- Fully Computerized Design With Self-Diagnostics System, Display Erroneous Message On Touch Screen, Easy For Trouble-Shooting!

- Quickly Molds Changing System, Saving Cost and Productive Cycle Time.

- All Function Control-On-Board Design, Easy for Operator Changing Data and Modifying Setting Directly On Touch Screen.

- The Feature Of Injection Blow Molding Machine, Not Only Bottle Surface Shining, But Also Bottle Body Seamless, Excellent For Production Smaller Bottle.

- Hydraulic Is Close Loop System, Controlled By Proportion Pressure and Flow Rate Precisely.

- Mold Seat Is Turret-Typed Design, Adopt Angular Index Device To Ensure Accurate Orientation.

| Model | FS-IB 60 | FS-IB 80 | ||

| Screw Diameter(mm) | 45 | 63 | ||

| Screw L/D ratio(L/D) | 20/1 | 20/1 | ||

| Screw-Speed Range (PRM) | 0-180 | 0-180 | ||

| *Figures and data are subject to change without notice due to constant research and development. | ||||

| EXPOSITION OF FULL SHINE'S MACHINE MODEL | |||||

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| Model | FS-IB 60 | FS-IB 80 | ||

|---|---|---|---|---|

| 1 | Injection | |||

| 2 | Screw diameter | mm | 45 | 63 |

| 3 | Screw L/D ratio | L/D | 20/1 | 20/1 |

| 4 | Screw-speed range | PRM | 0-180 | 0-180 |

| 5 | Screw- stroke | mm | 127 | 250 |

| 6 | Max.shot-weight | GRAM | 264 | 740 |

| 7 | Mold clamping(injection unit) | |||

| 8 | Injection mold Opening stroke | mm | 127 | 150 |

| 9 | Injection mold clamping force | ton | 60 | 80 |

| 10 | Trigger bar length | mm | 670 | 780 |

| 11 | Max swing radius | mm | 460 | 570 |

| 12 | Mold clamping(Blowing) | |||

| 13 | Blow mold opening stroke | mm | 127 | 150 |

| 14 | Blow mold clamping force | ton | 10 | 15 |

| 15 | Power system | |||

| 16 | Pump motor | hp | 30/20 | 30/30 |

| 17 | Pump pressure | kg/cm2 | 170 | 180 |

| 18 | Heating capacity | kw | 7 | 10 |

| 19 | Heating zone | point | 4 | 6 |

| 20 | Air consumption(Approx) | m3/hr | 35 | 40 |

| 21 | Air pressure | bar | 6-10 | 10-15 |

| 22 | Oil tank capacity | L | 300 | 1000 |

| 23 | Total power consumption | kw | 50 | 60 |

| 24 | Machine dimension | m | 4x1.6x1.9 | 5.5x1.9x2.5 |

| 25 | Machine weight | ton | 6 | 8.5 |

|

Sample bottles |

Sample bottles |

Operation Panel |

Turret-Typed Mold Seat |

|

Mold |

|