CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles.

Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome.

Co-extrusion application is the advanced technology by the leading brand: Full Shine.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | FS-40 PSSD | FS-45 PSSD | FS-55 PSSD | FS-65 PSSD | FS-75 PSSD | FS-55 PSSC | FS-65 PSSC | FS-75 PSSC | ||

| Style | Double/single die head/single die holder | Double color/single head single mold frame | ||||||||

| 1 | Use plastic | PE | PE | PE | PE | PE | PE | PE | PE | |

| 2 | Screw diameter | m/m | 40/25 | 45/25 | 55/25 | 65/25 | 75/25 | 55/55 | 65/65 | 75/75 |

| 3 | Screw ratio | L/D | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| 4 | Screw speed | r.p.m. | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 | 15-60 | 15-60 | 15-58 |

| 5 | Inverter motor | HP | 5/2 | 7.5/2 | 10/2 | 15/2 | 25/2 | 10/10 | 15/15 | 25/25 |

| 6 | Pump drive horsepower | HP | 5 | 7.5 | 10 | 10 | 15 | 10 | 10 | 15 |

| 7 | Air compressor with horsepower | HP | 5 | 5 | 7.5 | 7.5 | 10 | 7.5 | 7.5 | 10 |

| 8 | air pressure | Kg/cm2 | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 |

| 9 | Clamping pressure | Ton | 2.8 | 3.9 | 4.4 | 6.9 | 10 | 4.4 | 6.9 | 10 |

| 10 | Fuel tank capacity | Gallon | 38 | 55 | 60 | 80 | 120 | 60 | 80 | 120 |

| 11 | Heating points | ZONE | 6 | 6 | 6 | 7 | 7 | 6 | 6 | 7 |

| 12 | Heating capacity | KW | 9.5 | 12 | 15 | 19.5 | 22 | 19 | 24.5 | 26 |

| 13 | Total power | KW | 19 | 25 | 32 | 40.5 | 44 | 43 | 56 | 77 |

| 14 | Extrusion amount | Kg/hr | 15 | 24 | 42 | 55 | 75 | 42 | 55 | 75 |

| 15 | Empty cycle per hour | time/hr | 1285 | 1030 | 880 | 720 | 650 | 880 | 720 | 600 |

| 16 | Product capacity | c.c./L | 15-500 | 60-1000 | 150-2500 | 1L-5L | 1L-10L | 150-2500 | 1L-5L | 1L-10L |

| 17 | product weight | g. | 5-40 | 10-100 | 20-170 | 40-280 | 80-500 | 20-170 | 40-280 | 80-500 |

| 18 | Maximum and minimum product diameter | m/m | 10-75 | 20-100 | 30-140 | 50-200 | 80-260 | 30-140 | 50-200 | 80-260 |

| 19 | Die mouth diameter | m/m | 50 | 56 | 80 | 150 | 200 | 80 | 150 | 200 |

| 20 | Mold center distance | m/m | * | * | * | * | * | * | * | * |

| 21 | Open and close mold limit | m/m | 50-320 | 50-410 | 140-540 | 160-670 | 50-410 | 140-540 | 160-670 | 160-670 |

| 22 | Die length | m/m | 146-266 | 155-290 | 160-380 | 223-426 | 155-290 | 160-380 | 223-426 | 240-460 |

| 23 | Die width | m/m | 300 | 320 | 360 | 430 | 320 | 360 | 430 | 430 |

| 24 | Machine net weight | Kg | 3300 | 3800 | 4700 | 7600 | 3800 | 4700 | 7600 | 7300 |

| 25 | Machine size | m | 2.6*1.85*2.7 | 3*1.9*2.8 | 3.1*2*2.8 | 3.6*1.6*3.1 | 4.2*1.7*3.2 | 3.1*2*2.8 | 3.6*1.6*3.1 | 4.2*1.7*3.2 |

|

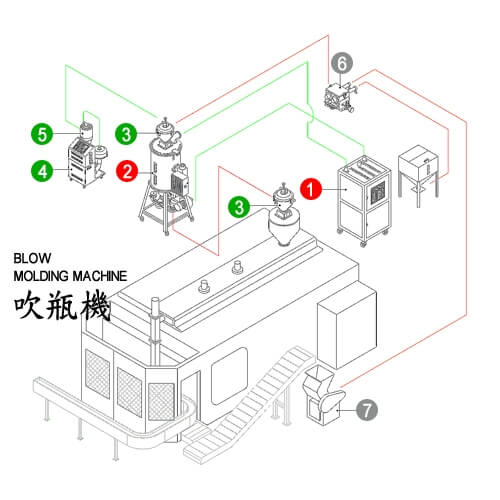

Top view side of co-extrusion 2 layers blow molding machine |

2 layers co extrusion bottles with view stripe line |

Machine photo co-extrusion 2 layers blow molding machine |

2 layers co-extrusion double die head |

|

Blow pin unit |

Barrel and screw set with fans |

2 layers co-extrusion double die head |

Top view side of co-extrusion 2 layers blow molding machine |

|

3 layers co-extrusion double die head |

3 layers co-extrusion double die head with hot cutter |

|

Mask/Closed Wound Drainage Systems |

Household/Cosmetics |

Household/Cleaning product bottle |

|

Household/Cosmetics |

Household/Cosmetics |

Closed Wound Drainage Systems |

|

Toys |

Automotive |

Household/Cosmetics |

|

Outdoor supplies/Bird balls |

Household/Cleaning product bottle |

Agro/ Chemical bottle |

|

Pesticide bottle |

Household/Cosmetics |

Jerry Can Making Machine |

|

Mascara bottle |