Related Industries

Products

View More :

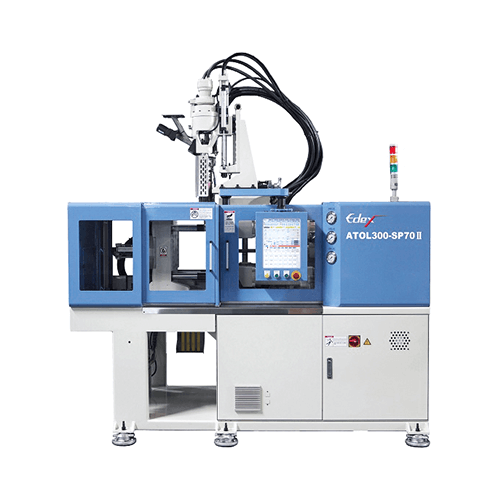

Double injection molding machine – HDC series

Categories : Two Color Injection Molding Machine

The standard HDC series has two parallel horizontal injection unit to be able to produce a 2-color and 2 plastic material in a time to save time and increase the productivity. To equip Huarong&rsqu...

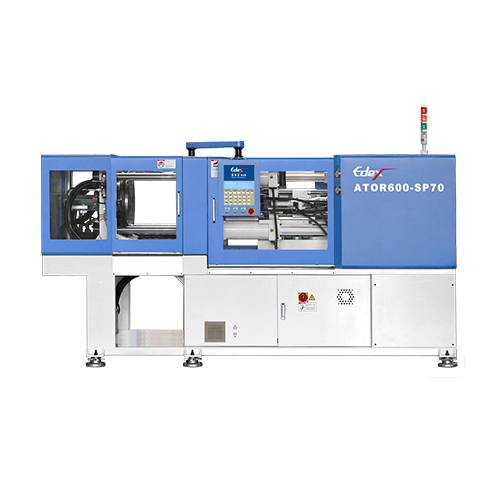

ATOL- Horizontal Multi-color/resin Injection Molding Machine

Categories : Two Color Injection Molding Machine

● Single, dual, triple color/resin in one machine. ● Suits for Plunger type injection or screw type injection system. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial plat...

Dual / Two Color Injection Molding Machine DNT Series

Categories : Two Color Injection Molding Machine

Dual color injection molding machines are dual color demand with two injection units that enable to perform two color at one time and spare second processing time.