Plastic Injection Molding Machine - TX Series

Categories : Double Toggle Injection Molding Machine

A performance-proven plastic injection molding machine with a faster injection speed

Two Platen Injection Molding Machine (LM Series)

Categories : Double Toggle Injection Molding Machine

It is medium and large scale injection molding machine. It is applicable to automotive industry such as bumper and

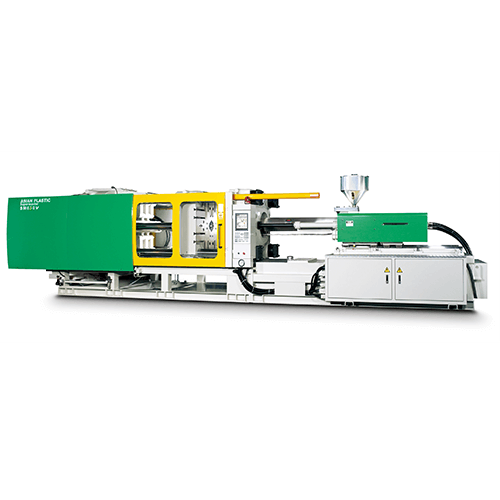

Double Toggle Injection Molding Machine (SMV Series)

Categories : Double Toggle Injection Molding Machine

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Mul...

Heavy Duty Double Toggle Injection Molding Machine

Categories : Double Toggle Injection Molding Machine

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision...