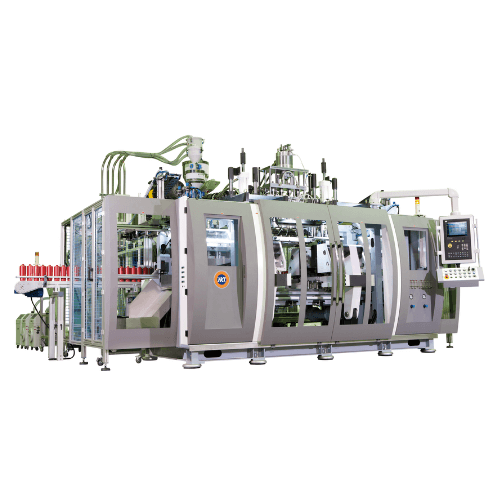

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle

Categories : Continuous Extrusion Blow Molding Machine

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle Double Head, Double Station HDPE bottle blow moulding machine

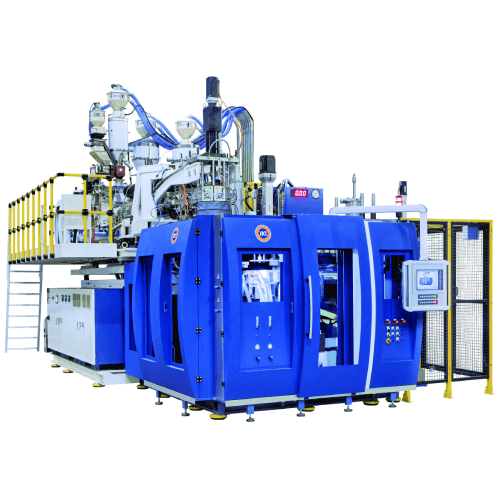

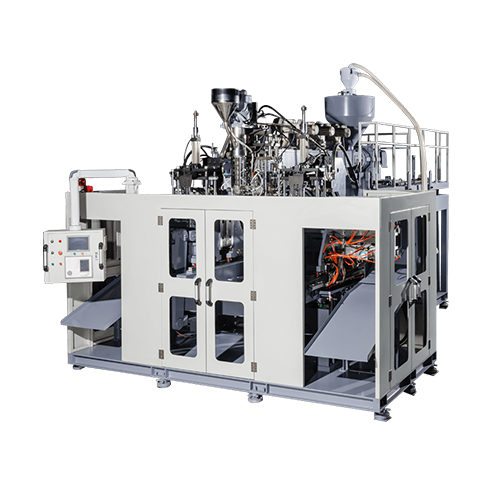

Blow Molding Machine PBSS SERIES - 905 / 1005 (S / D / T / Q)

Categories : Continuous Extrusion Blow Molding Machine

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production requirement...

Blow Moulding Machine for Jerrycan, Plastic Bottle, L-ring Drum

Categories : Continuous Extrusion Blow Molding Machine

Blow Moulding Machine for Jerrycan Plastic Bottle, L-ring Drum

Blow Molding Machine PBS 905 Series

Categories : Continuous Extrusion Blow Molding Machine

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

All Electric Single Station Blow Moulding Machine For 20lt Jerry Can, 3 Layer

Categories : Continuous Extrusion Blow Molding Machine

All Electric Blow Moulding Machine with a single head single station model was exhibited. In compliance to today’s global topic for a friendly environment, low energy consumption, less plasti...

Continuous Extrusion Blow Molding Machine with In Mold Labeling

Categories : Continuous Extrusion Blow Molding Machine

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer...

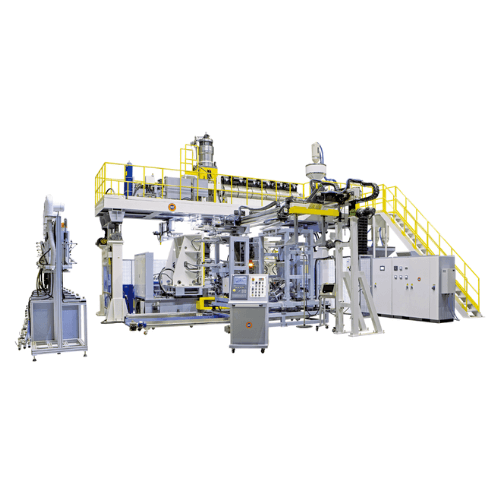

Accumulative Extrusion Blow Molding Machine for Medium to Large Containers

Categories : Continuous Extrusion Blow Molding Machine

The entire extruder can be adjusted automatically in an upward/downward direction through hydraulic power.

Continuous Extrusion Blow Molding Machine-Single Station

Categories : Continuous Extrusion Blow Molding Machine

Energy Saving. Using one hybrid servo motor to control all machine actions. Power consumption is less than a general hydraulic machine by 20~45%, easy to reach energy saving and carbon reduction go...

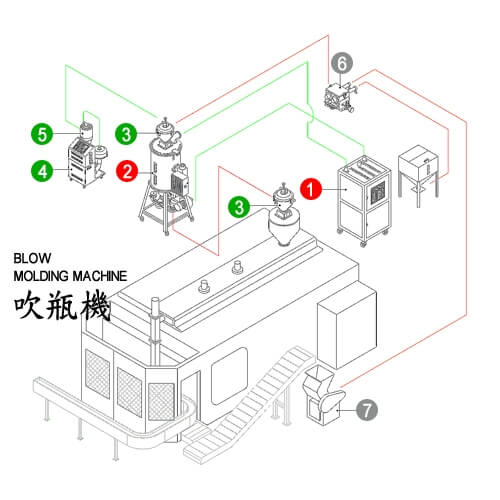

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Continuous Extrusion Blow Molding Machine

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

Continuous Extrusion Blow Molding Machine with Visi-Strip function

Categories : Continuous Extrusion Blow Molding Machine

This series is excellent for producing containers such as engine oil bottles, machine oil bottles, gasoline bottles, and similar containers. A small screw can be specially installed to indicate the...

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot

Categories : Continuous Extrusion Blow Molding Machine

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot

Continuous Extrusion Blow Molding Machine for Large Containers

Categories : Continuous Extrusion Blow Molding Machine

This series is single station extrusion blow molding machine for containers from 10L to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer re...

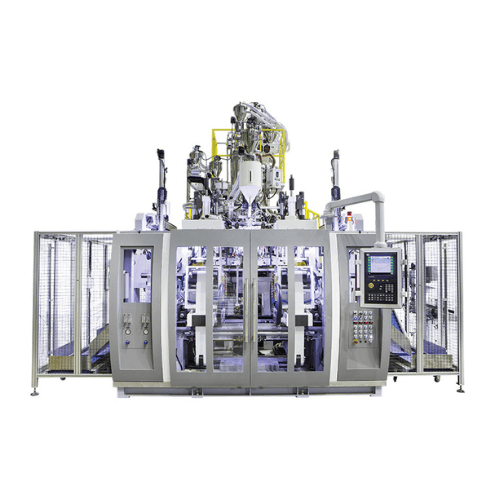

Fully Electric Extrusion Blow Molding Machine - Dual Diehead & Single Station

Categories : Continuous Extrusion Blow Molding Machine

Full electric movement, energy saving 15%~40%. Fully Electric Extrusion Blow Molding Machine - Dual Diehead & Single Station

Blow Molding Machine Multi Layer Series

Categories : Continuous Extrusion Blow Molding Machine

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottl...

Continuous Extrusion Blow Molding Machine -Double Station

Categories : Continuous Extrusion Blow Molding Machine

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer...

2 Layer Co-Extrusion Blow Moulding Machine for 200ml, 400ml Shampoo Bottle

Categories : Continuous Extrusion Blow Molding Machine

2 Layer Co-Extrusion Blow Moulding Machine for 200ml, 400ml Shampoo Bottle Quad Head, Double Station

Continuous Extrusion Blow Molding Machine for Small Bottles

Categories : Continuous Extrusion Blow Molding Machine

This model is a blow molding machine for high speed production of high quality small bottles. This machine offers PLC control, and linear guide in blowing unit for shorter cycle times and much high...

Medium Co-extrusion Blow Molding Machine – Double Station

Categories : Continuous Extrusion Blow Molding Machine

Medium Co Extrusion - Continuous Type Blow Molding Machine Chen Way Machinery is well-known for its 20L three-layer blow molding machines. Three-layer co extrusion blow molding machines are the mo...

Medium Co-extrusion Blow Molding Machine

Categories : Continuous Extrusion Blow Molding Machine

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C...

Small Blow Molding Machine

Categories : Continuous Extrusion Blow Molding Machine

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical us...

Medium Blow Molding Machine - Double Station

Categories : Continuous Extrusion Blow Molding Machine

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapt...