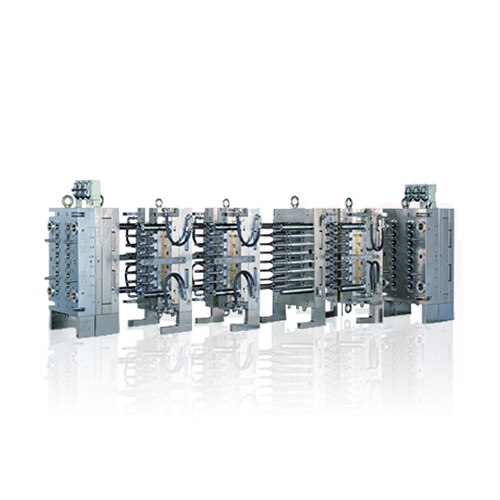

(1) The label is taken into the reach of the mold by means of a handling unit.

(2) The label is transferred and fixed in place (vacuum, static charge) within the cavity range.

(3) The label inserted is rear blow molding inside the mold .

(4) The finished part is removed while a new label is inserted at the same time.

- Provides superior performance and enhanced efficiency.

- Labels are impermeable to moisture to minimize chances of peels and cracks.

- Printed labels are smooth and unblemished.

- Anti-counterfeit function.

|

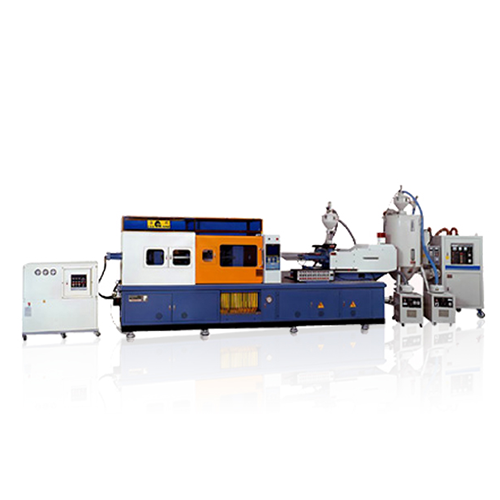

Model |

CM-65DH-IML |

||

|

Model |

Material to be Used |

|

PE/PP |

|

Screw Diameter |

mm |

Ø65 |

|

|

L/D Ratio |

|

24/1 |

|

|

Screw Speed Range (PE)/rpm |

rpm |

15-65 |

|

|

Inverter Motor |

HP |

20 |

|

|

Max. Extrusive Capacity/Hour |

kgs |

60 |

|

|

Heating Zone (Barrel) |

zone |

3 |

|

|

Heating Capacity (Barrel) |

kw |

10.8 |

|

|

Die head |

Heating Zone (Diehead) |

zone |

3 |

|

Heating Capacity (Diehead) |

kw |

11.9 |

|

|

Double Mold Center Distance |

mm |

140 |

|

|

Mold Plate |

Max. Opening Stroke |

mm |

550 |

|

Min. Close Stroke |

mm |

172 |

|

|

Mold Clamping Force |

ton |

7.5 |

|

|

Hydraulic System |

Hydraulic Pump Motor |

HP |

15 |

|

Hydraulic Oil Pressure |

kg/cm2 |

100 |

|

|

Oil Tank Capacity |

gallon |

85 |

|

|

Product |

Product Weight (Max.) |

g |

140 |

|

Product Dia. (Min./Max.) |

mm |

50-110 |

|

|

Product Capacity (Min./Max.) |

ml |

500-2000 |

|

|

Total Power Consumption |

kw |

52.6 |

|

|

Weight of Machine |

ton |

6 |

|

* All models can be upgraded to hybrid or fully electric type by servo motor control.

Plastic containers for detergents

Shampoo

Cleaners

Lotions