Automatic Blow Molding Machines

Automatic blow molding machines are used to produce hollow plastic products efficiently and consistently. These machines are essential in packaging, automotive, medical, and consumer goods industries for forming containers, bottles, tanks, and other shapes.

PRM-Taiwan showcases various automatic blow molding technologies, including Co Extrusion Blow Molding Machines, Full Automatic Blow Molding Machines, Pneumatic Extrusion Blow Molding Machines, Roll on Hollow Ball Making Machines, Semi Automatic Blow Molding Machines, and Stretch Blow Molding Machines—ideal for meeting diverse production needs.

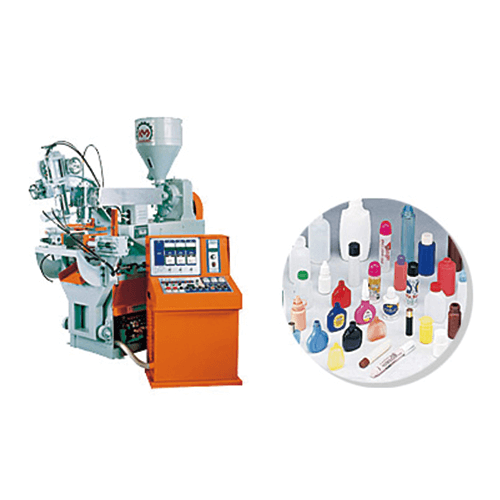

Pneumatic Extrusion Blow Molding Machine

Categories : Pneumatic Extrusion Blow Molding Machine

This series machine with special features which is designed especially for producing the drug bottle, toy, popsicle and etc. This type of machine can produce various material such as PP, PE, PVC. T...

PET Stretch Blow Molding Machine for Wide Mouth / Large Containers

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideal...

PET Automatic Stretch Blow Molding Machine for Small Mouth Jar/Container

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideal...

PP Stretch Blow Molding Machine

Categories : Stretch Blow Molding Machine

This PP bottle blow machine is dedicated to the production of pharmaceutical packaging and high temperature hot filling heat resistant bottles. Today the chemical resistance and suitability for ste...

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and fo...

Blow Molding Machine PBA Series

Categories : Pneumatic Extrusion Blow Molding Machine

These machines are high cycle pneumatic blow-molding machines, suitable for popsicles & wide variety small size bottles.

Blow Molding Machine PBS 905PC SERIERS

Categories : Stretch Blow Molding Machine

The PBS-905PC Special Purpose Blow Molding Machine is specially designed with an advance German type die head, featuring "first-in, first-out" performance. It is ideal for producing high ...

Double Layer Accumulator Head Blow Moulding Machines

Categories : Automatic Blow Molding Machines

Double Layer Accumulator Head Blow Molding Machines

Semi-Automatic Stretch Blow Molding Machine

Categories : Semi Automatic Blow Molding Machines

Application:Wide-neck jar, large volume bottle, vase, Oval, Off center, Petaloid, Square, Flat, Round bottles yicheen Suitable for High-priced and irregular shape bottle’ vase LCD sc...

Accumulator Double Head Blow Moulding Machines

Categories : Automatic Blow Molding Machines

Accumulator Double Head Blow Molding Machines Mono Layer and Multi-layer Accumulator Head Type Blow Moulding Machine. For producing 20 liter to 1000 liter volume, all kinds of jerry can, contai...

Continuous Co-Extrusion Blow Molding Machine (Multi Layer)

Categories : Co Extrusion Blow Molding Machine

This series is specified for producing particular containers that are fully sealed, light resistant, heat resistant, anti-bacterial, durable, anti-static, corrosion resistant, non-toxic…etc.

Pneumatic Extrusion Blow Molding Machine - Rotary Type

Categories : Pneumatic Extrusion Blow Molding Machine

This machine is mainly suitable for plastic package with being blow up from side. Such as the plastic bottles for ice lolly, popsicle, or frozen bar. The main character of this machine is its simpl...

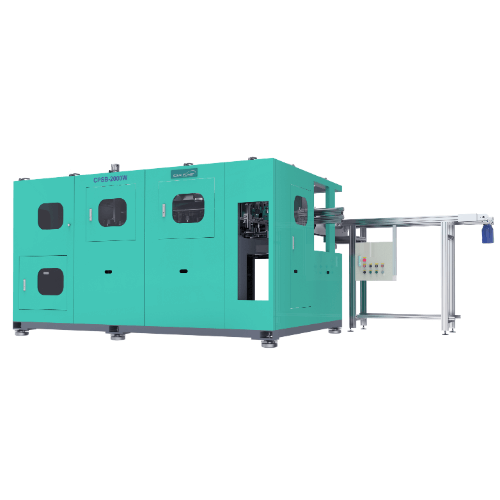

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Co Extrusion Blow Molding Machine

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is ...

PET Semi-Auto Stretch Blow Molding Machine

Categories : Semi Automatic Blow Molding Machines

This semi-auto stretch blow molding machine is the most cost effective solution for low level production of bottles, containers, and jars in small to large sizes.

Accumulator Head Blow Moulding Machines-40 Liter Float

Categories : Automatic Blow Molding Machines

Accumulator Head Blow Molding Machines-40 Liter Float

Accumulator Head Blow Moulding Machine for 400-600lt Fuel Tank

Categories : Automatic Blow Molding Machines

Accumulator Head Blow Moulding Machine for 400-600lt Fuel Tank

All Electric Blow Moulding Machine for 200ml, 500ml Shampoo Bottle

Categories : Automatic Blow Molding Machines

All Electric Blow Moulding Machine for 800ml Bottle with view stripe High Efficiency and Eco-Friendly Design The FKI All-Electric HDPE Bottle Making Machine is specifically engineered for pro...

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and fo...

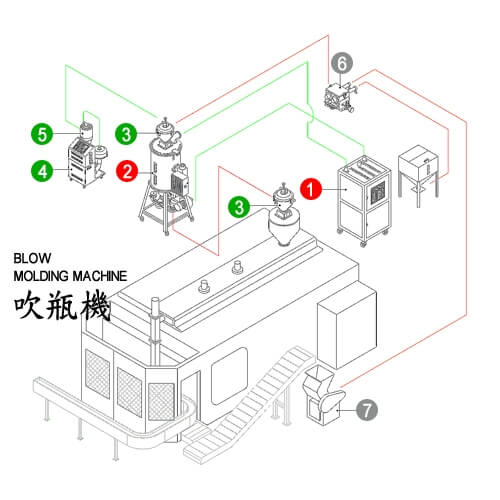

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Semi Automatic Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

Large Volume PET Blow Molding Machine-W/L Series

Categories : Stretch Blow Molding Machine

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structu...

5 Gallon Bottles PET Fully Electric Stretch Blow Molding Machine

Categories : Pneumatic Extrusion Blow Molding Machine

CMSQ1 PET all electric stretch blow molding machines are suited for 3 gallon to 5 gallon water bottles.

PET Automatic Stretch Blow Molding Machine for Hot Filling Bottles

Categories : Stretch Blow Molding Machine

The CMA (H) series stretch blow molding machines produce hot filling bottles for products such as fruit juices, isotonic drinks and RTD tea. These machines have a unique design according to the eff...

Extrusion Blow Molding Machine PK-CS/CD/CS3/CS4/CS8/CS12

Categories : Automatic Blow Molding Machines

Single Station Single/Double/Triple/Quadruple..12 Head Horizontal Operated Clamping System Production Volume:2ml~35L Multi layers: Co-Extrusion 1-6 Layers Multi cavities: 1~12 cav...

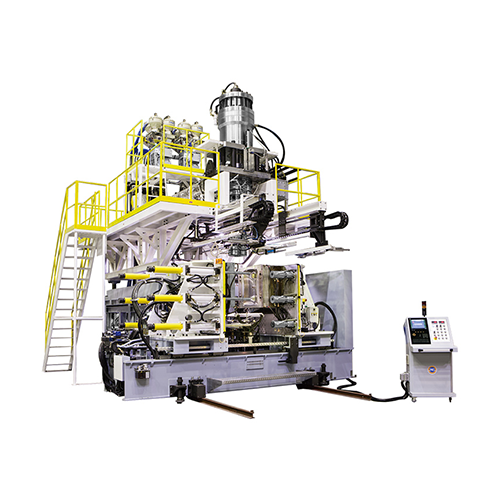

ENS Series-Accumulator type

Categories : Automatic Blow Molding Machines

Accumulator type - Design for big size products, something like automotive parts, hospital bed, mobile toilet...etc. Taking out robot is optional.