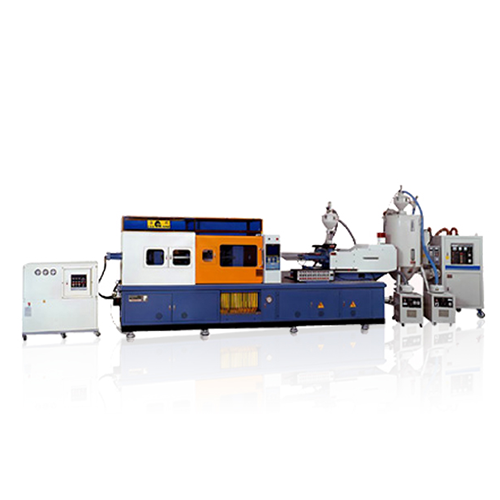

Classification : Extrusion Blow Molding

Country: Taiwan

Phone: 886-4-22332281

Fax: 886-4-22306247

Contact Person: Sales Department

This series machine with special features which is designed especially for producing the drug bottle, toy, popsicle and etc. This type of machine can produce various material such as PP, PE, PVC. This is the most economical and high performance machinery nowadays.

- It is the most economical and high performance machinery for producing small bottles and containers. Such as drug bottle, toy, popsicle / frozen bar, etc.

- Screw can be designed upon customer's request; the screw & barrel are made of special steel and processed by nitriding.

- Water cooling system controls feeding zone temperature.

- It also can work with hydraulic power pack for clamping.

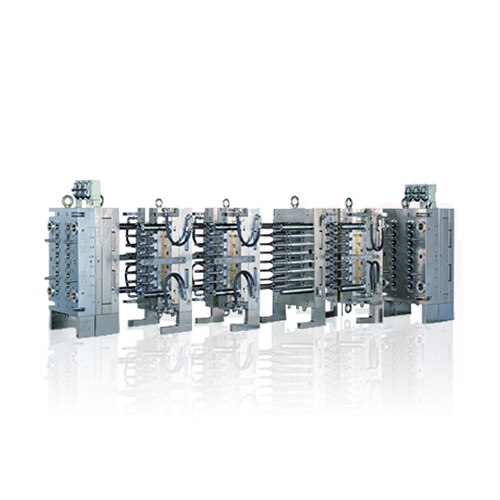

| Model | CM-40P | CM-40E | ||

| Model | Material to be Used | PE | PE | |

| Screw Diameter | mm | Ø40 | Ø40 | |

| L/D Ratio | 22/1 | 22/1 | ||

| Screw Speed (PE)/min | rpm | 15-85 | 15-85 | |

| Inverter Motor | HP | 3 | 5 | |

| Max. Extrusive Capacity/Hour | kgs | 13 | 13 | |

| Heating Zone (Barrel) | zone | 2 | 2 | |

| Heating Capacity (Barrel) | kw | 3.2 | 3.2 | |

| Die head | Heating Zone (Diehead) | zone | 2 | 2 |

| Heating Capacity (Diehead) | kw | 2.8 | 2.8 | |

| Double Mold Center Distance | mm | - | - | |

| Mold Plate | Max. Opening Stroke | mm | 230 | 230 |

| Min. Close Stroke | mm | 93 | 93 | |

| Mold Clamping Force | ton | |||

| Hydraulic System | Hydraulic Pump Motor | HP | - | - |

| Hydraulic Oil Pressure | kg/cm2 | - | - | |

| Oil Tank Capacity | gallon | - | - | |

| Product | Product Weight (Max.) | g | 35 | 35 |

| Product Dia. (Min./Max.) | mm | 10-80 | 10-80 | |

| Product Capacity (Min./Max.) | ml | 20-300 | 20-300 | |

| Total Power Consumption | kw | 8.2 | 10 | |

| Weight of Machine | ton | 0.55 | 0.65 | |

* All models can be upgraded to hybrid or fully electric type by servo motor control.