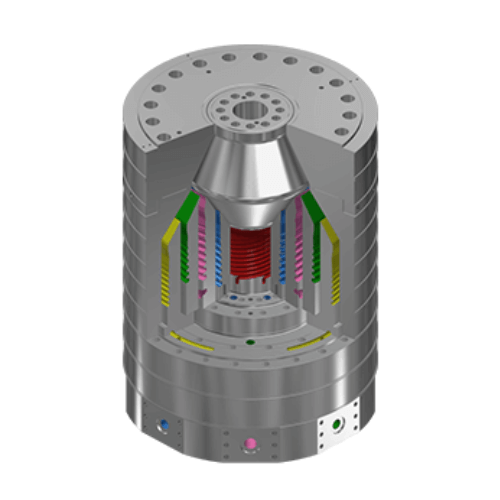

5 Layer Die Head

Categories : Multi Layer Extrusion Die Head

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted po...

Single Layer Die Head

Categories : Multi Layer Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

ABA Double Die Head

Categories : Multi Layer Extrusion Die Head

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted po...

Two Layer / ABA Die Head

Categories : Multi Layer Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

7 Layer Die Head

Categories : Multi Layer Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

Two Color And Multi-Color Die Head

Categories : Multi Layer Extrusion Die Head

•Die head can be manufactured to meet customer’s specific extruding capacity and bag width. •Precision construction throughout assures maximum uniformity of film thickness. •Di...

Stacked & Multilayer Type Die Heads

Categories : Multi Layer Extrusion Die Head

+For all kinds of blown film machines and it is suitable for multi-layer products. +The stacked design provides high stability & good quality.

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

Categories : Multi Layer Extrusion Die Head

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

Single Layer Die Head for HDPE or LDPE or PP

Categories : Multi Layer Extrusion Die Head

+Suitable for HDPE, LDPE & LLDPE Blown Film Machine. +Low pressure and spiral design provide high stability & high production. +All steel is made of Japanese SCM-440 through strict &...

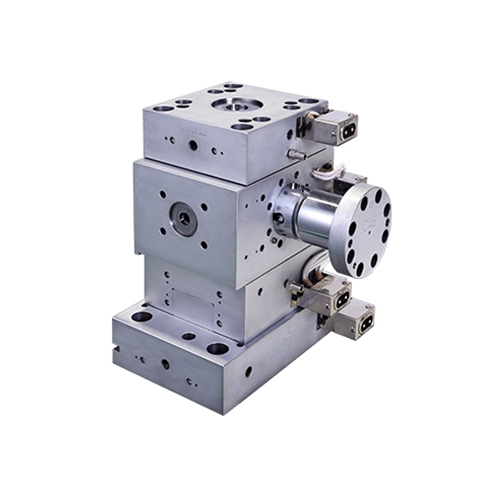

Fix / Variable / Rapid Geometry Feedblock

Categories : Multi Layer Extrusion Die Head

FIX GEOMETRY Simple manifold structure, few retention points Customized manifold design, 2 or 4 inlets, for different Extrusion Die inlet as required by the customer Precision internal manifold des...