Classification : EXTRUSION PERIPHERALS

Country: Taiwan

Phone: 886-4-2630-3228

Fax: 886-4-2630-3208

Contact Person: Rose Wang #110 /Emma Liao #126

-

2-layer

Layer structure: AB.

Extrusion capacity: 100 ~ 600 kg. -

3-layer

Layer structure: ABC / ABA.

Extrusion capacity: 100 ~ 600 kg. -

4-layer

Layer structure: DABC.

Extrusion capacity: 100 ~ 600 kg. -

5-layer

Layer structure: ABCDE ABCBA.

Extrusion capacity: 100 ~ 600 kg. -

7-layer

Layer structure: ABCDCBA.

Extrusion capacity: 100 ~ 600 kg. -

10-layer

Layer structure: ABCBAABCBD.

Extrusion capacity: 100 ~ 600 kg. -

Note:

1. Customization according to customer requirements, upon request.

2. Work with Extrusion Dies by third partied is acceptable except PVC.

3. Applicable polymers: General polymers.

-

2-layer

Layer structure: AB.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

3-layer

Layer structure: ABC / ABA.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

5-layer

Layer structure: ABCDE ABCBA.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

7-layer

Layer structure: ABCDCBA.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

11-layer

Layer structure: KABCBDEFGHK.

Extrusion capacity: 100 ~ 800 kg.

Rate adjustment in individual layer: Up to 5%. -

Note:

1. Customization according to customer requirements, upon request.

2. Work with Extrusion Dies by third partied is acceptable except PVC.

3. Applicable polymers: General polymers.

-

2-layer

Layer structure: AB.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

3-layer

Layer structure: ABC / ABA.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

5-layer

Layer structure: ABCDE ABCBA.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

7-layer

Layer structure: ABCDCBA.

Extrusion capacity: 100 ~ 600 kg.

Rate adjustment in individual layer: Up to 5%. -

11-layer

Layer structure: KABCBDEFGHK.

Extrusion capacity: 100 ~ 800 kg.

Rate adjustment in individual layer: Up to 5%. -

Note:

1. Customization according to customer requirements, upon request.

2. Work with Extrusion Dies by third partied is acceptable except PVC.

3. Applicable polymers: General polymers.

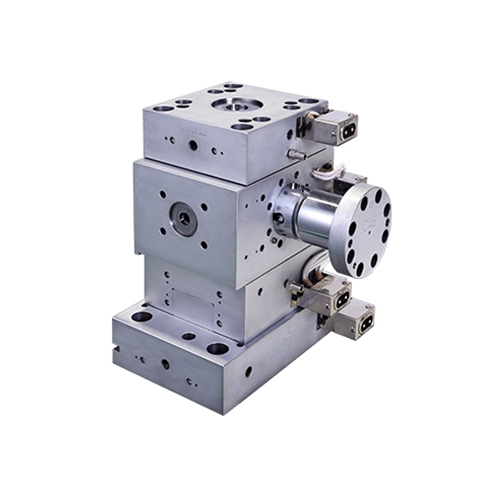

FIX GEOMETRY

- Simple manifold structure, few retention points

- Customized manifold design, 2 or 4 inlets, for different Extrusion Die inlet as required by the customer

- Precision internal manifold design along with special surface treatment

- Corrosion, heat and wear resistant design

- Manifold design varies with rheology property of polymer material to adapt to features and strength of rheology of melted polymers

- Applicable with multi-layer composite production requirements of different materials

SUITABLE AVAILABLE FOR HEAT SENSITIVE POLYMERS INCLUDING

ABS, PA, PC

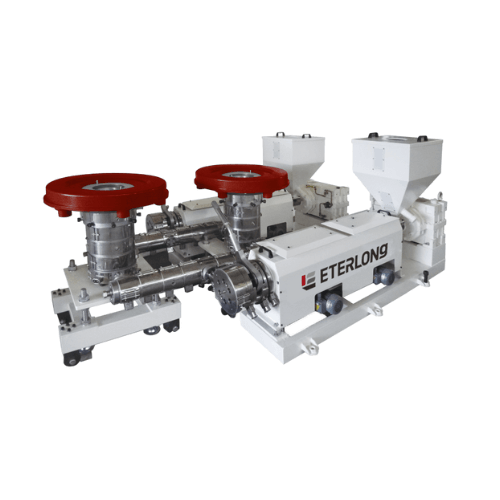

VARIABLE GEOMETRY

- Direct changing thickness of individual layers during production Easy operation, production costs reduction.

- Multi-layer space design according to product requirements.

- Interchangeable selector as required by customer to adapt to different products and changing layers required by the customer.

- Precision internal manifold design along with special surface treatment.

- Corrosion, heat, and wear resistant design.

- Adaptive to features and strength of rheology of melted polymers.

- Applicable with multi-layer composite production requirements of different materials.

SUITABLE APPLICABLE WITH GENERAL POLYMERS SUCH AS

PP/PE/PS

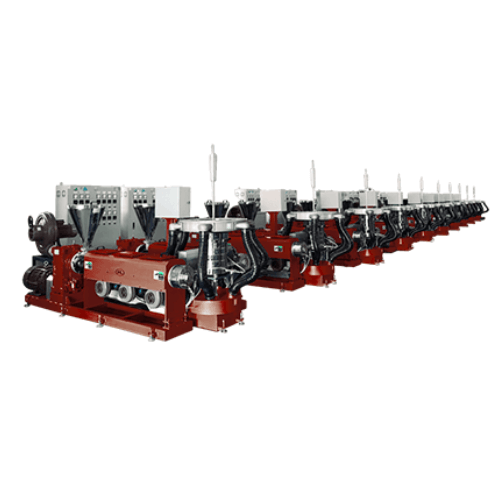

RAPID VARIABLE GEOMETRY

- Direct changing thickness of individual layers during production Easy operation, production costs reduction.

- Multi-layer space design according to product requirements.

- Interchangeable selector as required by customer to adapt to different products and changing layers required by the customer.

- Precision internal manifold design along with special surface treatment.

- Corrosion, heat, and wear resistant design.

- Adaptive to features and strength of rheology of melted polymers.

- Applicable with multi-layer composite production requirements of different materials.

SUITABLE APPLICABLE WITH GENERAL POLYMERS SUCH AS

PP/PE/PS