Automatic Blow Molding machine- A Series

Categories : Automatic Blow Molding Machines

This type is the pneumatic-clamping blow-molding machine, suitable for making popsicle (ice-lolly) & various small-size bottles. Extrusion is driven by the inverter motor with pulley-drive gear...

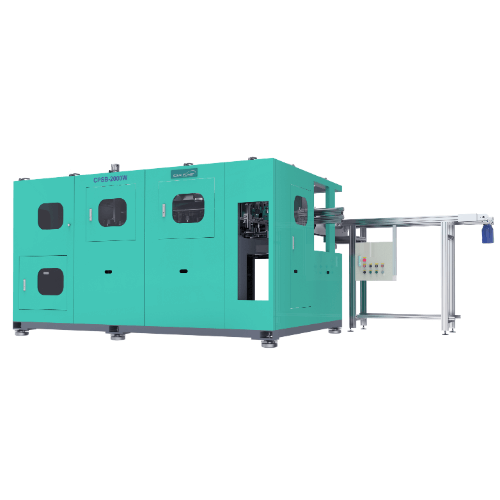

PET Fully Electric Stretch Blow Molding Machine

Categories : Electric Blow Molding Machines

A handle bottle makes it easier to carry and pour from a container to container. CMS series stretch blow molding machine equipped with a robot device is the choice of making bottle with handle. The...

Large Volume PET Blow Molding Machine-W/L Series

Categories : Automatic Blow Molding Machines

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structu...

5 Gallon Bottles PET Fully Electric Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

CMSQ1 PET all electric stretch blow molding machines are suited for 3 gallon to 5 gallon water bottles.

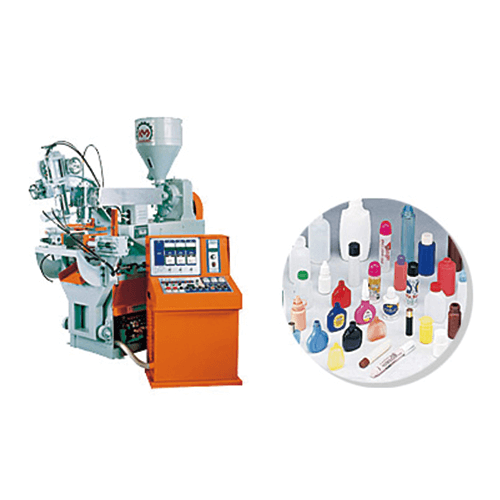

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical us...

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and fo...

PET Fully Electricity Stretch Blow Molding Machine for Jar and Large Containers

Categories : Electric Blow Molding Machines

-Servo-motor technology (preform transfer system – preform stretching – press clamping). -Energy savings. -Quiet. -Faster cycle times. -Reduced downtime and labor. -Optional jar preform...

Semi-Automatic Pet Stretch Blow Molding Machine FS-1000HD2

Categories : Automatic Blow Molding Machines

One Heating Machine One Stretching Machine. Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. Semi-auto PET Stretch Blow Molding Machin...

Blow Molding Machine PBS-605~705 Series

Categories : Horizontal Blow Molding Machines

Durable and horizontal traveling mold carriage combined with German linear motion guides for maximum stability. The series is excellent for producing medium and large sized containers. Available to...

Blow Molding Machine PBI SERIES

Categories : Extrusion Blow Molding Machines

Screw type with first-in and first-out accumulation type die head provide fast color change. 4 tie-bars for mold platens ensure uniform mold clamping.

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and fo...

Pneumatic Extrusion Blow Molding Machine - Rotary Type

Categories : Automatic Blow Molding Machines

This machine is mainly suitable for plastic package with being blow up from side. Such as the plastic bottles for ice lolly, popsicle, or frozen bar. The main character of this machine is its simpl...

PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

Categories : Electric Blow Molding Machines

PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

Continuous Extrusion Blow Molding Machine -Double Station

Categories : Horizontal Blow Molding Machines

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer...

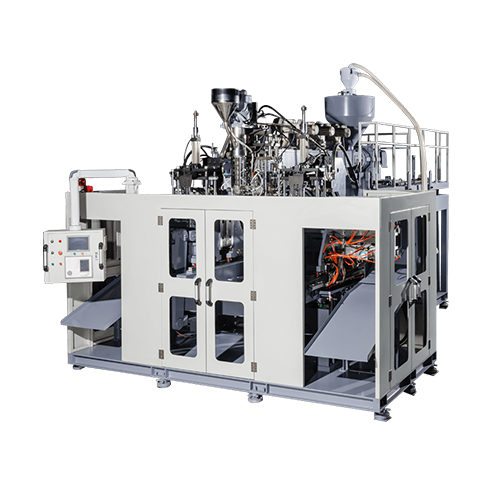

Medium Blow Molding Machine - Double Station

Categories : Electric Blow Molding Machines

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapt...

Blow Molding Machine Multi Layer Series

Categories : Electric Blow Molding Machines

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottl...

Blow Molding Machine PBA Series

Categories : Horizontal Blow Molding Machines

These machines are high cycle pneumatic blow-molding machines, suitable for popsicles & wide variety small size bottles.

Semi-Automatic PET Stretch Blow Molding Machine - FS 1000HD

Categories : Automatic Blow Molding Machines

One Heating Machine Two Stretching Machine. -Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. -Semi-auto PET Stretch Blow Molding Mach...

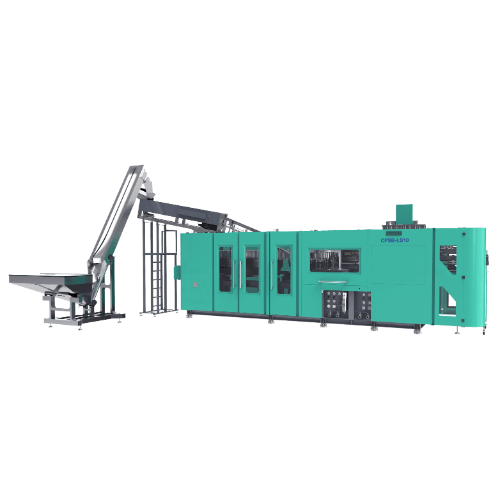

High Productivity PET Blow Molding Machine L Series

Categories : Horizontal Blow Molding Machines

High Productivity PET Blow Molding Machine