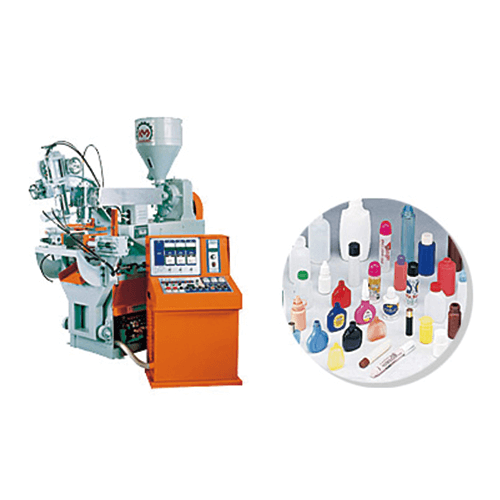

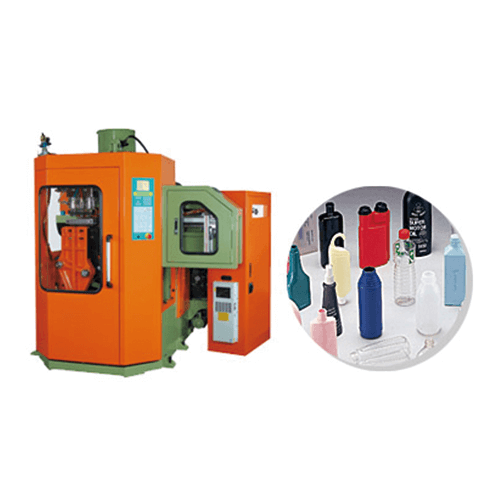

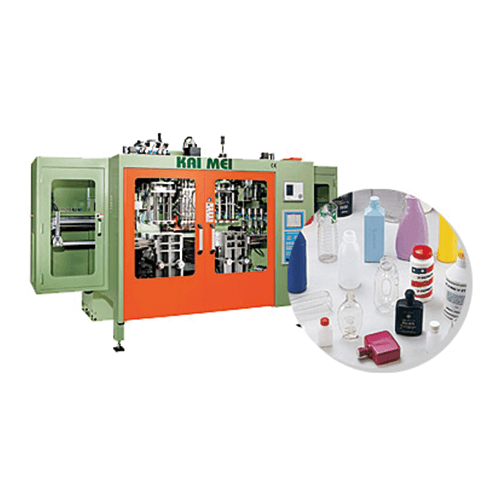

Classification : Blow Molding Machine

Country: Taiwan

Phone: 886-4-22777457

Fax: 886-4-22777455

Contact Person: Jean Lin

- Durable and horizontal traveling mold carriage combined with German linear motion guides for maximum stability. The series is excellent for producing medium and large sized containers.

- Available to equip with an auto deflashing device and take-out robot to achieve fully automatic and highly efficient production.

- 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

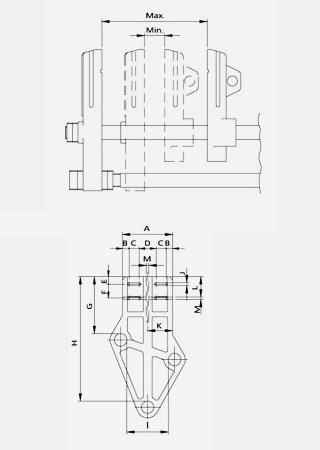

| NO. | PBS-605 | PBS-705 | NO. | PBS-605 | PBS-705 |

| Max. | 540 | 650 | F | 100 | 180 |

| Min. | 140 | 200 | G | 410 | 430 |

| A | 390 | 440 | H | 715 | 740 |

| B | 60 | 80 | I | 280 | 330 |

| C | 65 | 60 | J | 18 | 18 |

| D | 140 | 160 | K | 190 | 215 |

| E | 60 | 60 | L | 105 | 105 |

*All specifications and designs are subject to change without notice.

| Model No. | UNIT | PBS-605S | PBS-605D | PBS-605T | PBS-605Q |

| Max. product capacity | C.C. | 1,000-5,000 | 450-1,800 | 200-1,000 | 50-500 |

| Min. / Max. dia. of product | mm | 75-200 | 50-120 | 30-100 | 20-80 |

| Screw diameter | mm | 65 | 65 | 65 | 65 |

| Screw L/D ratio | L/D | 24/1 | 24/1 | 24/1 | 24/1 |

| Inverter motor | HP | 20 | 20 | 20 | 20 |

| Screw rotating speed | r.p.m. | 15-65 | 15-65 | 15-65 | 15-65 |

| Extruding capacity | kg/hr | 55 | 55 | 55 | 55 |

| Outer diameter of die mouth | mm | 150 | 65 | 50 | 40 |

| Mould center distance | mm | ~ | 140 | 120 | 100 |

| Clamping force | ton | 8.8 | 8.8 | 8.8 | 8.8 |

| Oil hydraulic drive motor | HP | 15 | 15 | 15 | 15 |

| Dry cycle | sec. | 4.2 | 4.2 | 5 | 5 |

| Air pressure | kg/cm2 | 6-8 | 6-8 | 6-8 | 6-8 |

| Air consumption | L/min | 750 | 750 | 750 | 750 |

| Total power consumption | kw/h | 38 | 40.5 | 42 | 46.7 |

| Machine net weight | kg | 4,800 | 4,800 | 4,800 | 4,800 |

| Gross weight | kg | 5,500 | 5,500 | 5,500 | 5,500 |

| Gross weight | m | 3.7x2.5x2.5 | 3.7x2.5x2.5 | 3.8x2.7x2.5 | 3.8x2.7x2.5 |

| Model No. | UNIT | PBS-705S | PBS-705D | PBS-705T | PBS-705Q |

| Max. product capacity | C.C. | 2,500-10,000 | 600-2,700 | 450-1,800 | 200-1,000 |

| Min. / Max. dia. of product | mm | 100-250 | 60-140 | 50-120 | 30-100 |

| Screw diameter | mm | 75 | 75 | 75 | 75 |

| Screw L/D ratio | L/D | 24/1 | 24/1 | 24/1 | 24/1 |

| Inverter motor | HP | 40 | 40 | 40 | 40 |

| Screw rotating speed | r.p.m. | 15-65 | 15-65 | 15-65 | 15-65 |

| Extruding capacity | kg/hr | 75 | 75 | 75 | 75 |

| Outer diameter of die mouth | mm | 200 | 80 | 65 | 50 |

| Mould center distance | mm | ~ | 160 | 140 | 120 |

| Clamping force | ton | 13 | 13 | 13 | 13 |

| Oil hydraulic drive motor | HP | 25 | 25 | 25 | 25 |

| Dry cycle | sec. | 5 | 5 | 5.2 | 5.2 |

| Air pressure | kg/cm2 | 6-8 | 6-8 | 6-8 | 6-8 |

| Air consumption | L/min | 1200 | 1200 | 1,200 | 1,200 |

| Total power consumption | kw/h | 64.9 | 66.4 | 67.3 | 75 |

| Machine net weight | kg | 5,000 | 5,000 | 6,500 | 6,500 |

| Gross weight | kg | 6,000 | 6,000 | 7,000 | 7,000 |

| Gross weight | m | 4.3x2.7x2.6 | 4.3x2.7x2.6 | 4.3x2.7x2.8 | 4.3x2.7x2.8 |

*All specifications and designs are subject to change without notice.