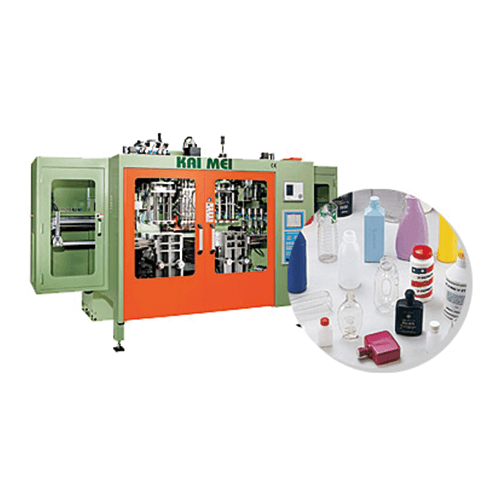

It is designed for small containers Mouth-to-Mouth design. Mouth-to-Mouth design can improve two-time production for double-station machines. It creates a unique and new mold design and auto cutting device. It can increase machine stability and decrease defective rates. This is the latest high-producion machine technology.

Powerful 4 tie-bars type mold clamping system combined with 8 die-head design. It can produce any kind of small and medium container at high speeds. Available to equip with auto deflashing device and take-out robot to achieve fully automatic and highly efficient production. Or it can equip with specialized take-out robot and conveyor to take out products from single side in order to have convenient production-line formulation.

| MODEL NO. | UNIT | PBSS-905O | PBSS-1005O |

| Prodcut max. capacity --Mouth-to-Mouth Bottle --Non Mouth-to-Mouth Bottle |

C.C. | 60-130 120-300 |

120-180 160-400 |

| Mould center distance | mm | 80*7 | 80*7 |

| Outer diameter of die mouth | mm | 35 | 35 |

| Min./Max. dia. Of product | mm | 35-55 | 35-55 |

| Screw Diameter | mm | 95 | 100 |

| Screw L/D Ratio | L/D | 24/1 | 24/1 |

| Inverter Motor | HP | 75 | 75 |

| Screw Speed | r.p.m | 15-65 | 15-65 |

| Extruding Capacity | Kg/hr | 150 | 180 |

| Clamping Force | Ton | 11 | 12 |

| Hydraulic Drive Motor | HP | 40 | 40 |

| Dry cycle | Sec. | 6.5*2 | 6.5*2 |

| Air Pressure | Kg/cm² | 8-10 | 8-10 |

| Air Consumption | L/min | 3000 | 3500 |

| Total Eletric Power | KW | 128 | 131 |

| Machine N.W. | Kg | 20000 |

22000 |

*All specifications and designs are subject to change without notice.