Shrink Sleeve Machinery

Shrink sleeve machines apply shrink labels or sleeves onto bottles, jars, and containers using heat or steam. This process ensures tight-fitting, tamper-evident packaging while enhancing branding and shelf appeal—ideal for beverages, detergents, personal care, and health products.

PRM-Taiwan features efficient shrink label & sleeve solutions with high-speed label application, synchronized cutting, and heat-shrink processing. These systems can be integrated into filling and capping lines to optimize packaging operations.

Doctoring Rewinder Machines INSPECT-l3 PLUS For Shrink Sleeve Inspection

Categories : Shrink Sleeve Machinery

INSPECT-J300 (I1)/J400 (I3)

Sleeve Rewinding and Inspection Machine - Reversible Series-FSP 250-2

Categories : Shrink Label & Sleeves

The FSP-250-2 is an ideal re-reeling machine for round roll material inspecting process such as printing, surface or the seaming quality of shrink sleeves. 2 motors driven system and memorized reve...

Seaming Machine K3 Plus

Categories : Shrink Label & Sleeves

Unwind Edge Guide System Independent Unwind, Forming and Rewind Tension Zones Frictionless Forming System Automatic Layflat Set-up Automatic Layflat Correction Direct Injection Solvent...

FP-X Turret Rewind Shrink Sleeve Seaming Machine

Categories : Shrink Label & Sleeves

HCI's new generation of FP-X high-speed turret rewind shrink sleeve seaming machines which meets the requirement of high-speed production, automatic roll-changing and online inspection. With r...

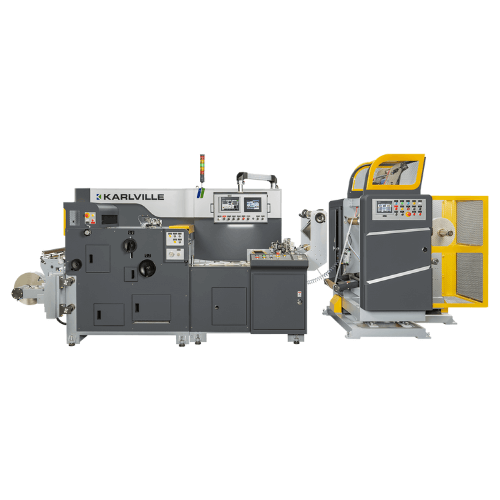

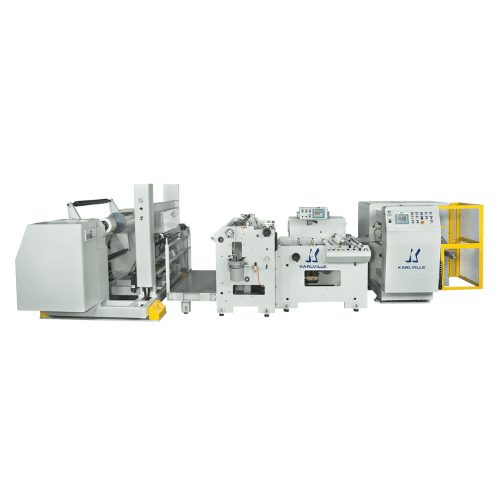

Seaming Machines SEAM-350D-UHS (K3)

Categories : Shrink Label & Sleeves

- Adjustable forming plate - Unwind perforation capability

Seaming Machines SEAM-350D-UHS-JUMBO (K5-J)

Categories : Shrink Label & Sleeves

SEAM-350D-UHS-JUMBO (K5-J)

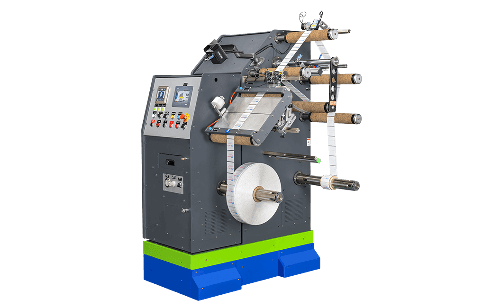

Shrink Label Re-reeling and Doctoring Machine-FSP Series

Categories : Shrink Label & Sleeves

-Efficient operation for inspect the shrink label center gluing quality. -Shrink Label printing and surface inspection. -The FSP Re-reeling and Doctoring Machine provides outstanding performance. I...

Sleeve Rewinding and Inspection Machine (Reversible) - FSP-250-2

Categories : Shrink Label & Sleeves

The FSP-250-2 is an ideal re-reeling machine for round roll material inspecting process such as printing, surface or the seaming quality of shrink sleeves. 2 motors driven system and memorized reve...

Shrink Sleeve Width Measuring -Sleeve Eye

Categories : Shrink Label & Sleeves

Sleeve Eye inspection system is designed exclusively for in line inspection of shrinkable label. It is capable of detecting lay flat width with ultrasonic system right after seaming process. Sleeve...

Seaming Machines SEAM-350D-UHS-COMPACT (K5-C)

Categories : Shrink Label & Sleeves

- Adjustable forming plate - Unwind turret cantilever - Rewind turret cantilever

Seaming Machines SEAM-350D-COMPACT (K4)

Categories : Shrink Label & Sleeves

-for Shrink sleeve. -Increase production. -Non stop Turret. Features -Increase production. -Decrease inspection time. -Reduce waste. -Decrease labor.

Seaming Machine SEAM-300/400 (K2)

Categories : Shrink Label & Sleeves

- Unwind edge guide system - Adjustable forming plate - Semi-automatic tension control - Rewind oscillation - Touchscreen control - EFD direct injection system - Proportional solvent speed control

Shrink Label Glue Sealing Machine (Sleeve Seaming Machine)-FK Series

Categories : Shrink Label & Sleeves

The most economical investment for producing center glue sealing of PVC shrink labels. Simplified design, easy to operate and maintain

Shrink Label Re-reeling and Doctoring Machine-FSP Series

Categories : Shrink Label & Sleeves

Efficient operation for inspect the shrink label center gluing quality. Shrink Label printing and surface inspection. The FSP Re-reeling and Doctoring Machine provides outstanding performance. It i...

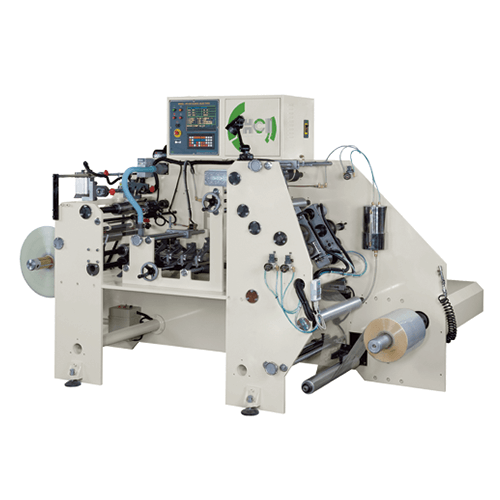

High Speed Shrink Sleeve Glue Sealing Machine (Sleeve Seaming Machine)-FP250

Categories : Shrink Label & Sleeves

Designed for the center seaming operation of shrink sleeves such as PVC, PS, PET, and POF...

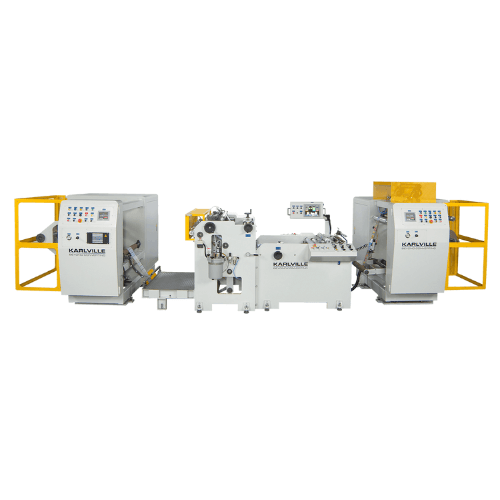

Seaming Machines K5 Plus

Categories : Shrink Label & Sleeves

The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. This new patented design makes the K5 PL...

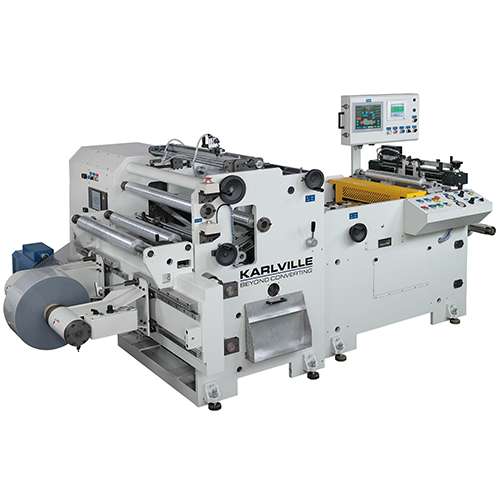

Economic Slitter with High Efficiency - Enova Series

Categories : Shrink Sleeve Machinery

Application and Materials: OPP, PET, CPP, PVC(rigid), Shrinkable PP Film, Cellophane, Paper, Silicon Coated Paper, Metalized Paper, Self-adhesive Paper, Aluminum Foil, Copper Foil, Thermal Transfer...

Doctoring Machine - REF-Q Series

Categories : Shrink Sleeve Machinery

Application and Materials: PVC shrinkable label tube

Auto Shrinkable Sleeve Machine-GSL-600

Categories : Shrink Sleeve Machinery

Suitable applications:For label insertion on containers of sundries, food,beverage, dairy products, and wine, medicines, and industrial products. Model : GSL-600

POF Heat Shrink Film

Categories : Shrink Sleeve Machinery

POF heat shrinkable film is an environmentally friendly shrink film, Multi-layer co-extrusion. It can be in direct contact with food. Benison provides single-wound and center folded materials, whic...