Classification : PVC Shrink Label Making Machine

Country: Taiwan

Phone: 886-4-2359-0632

Fax: 886-4-2359-0710

Contact Person: Mr. Alan Ho

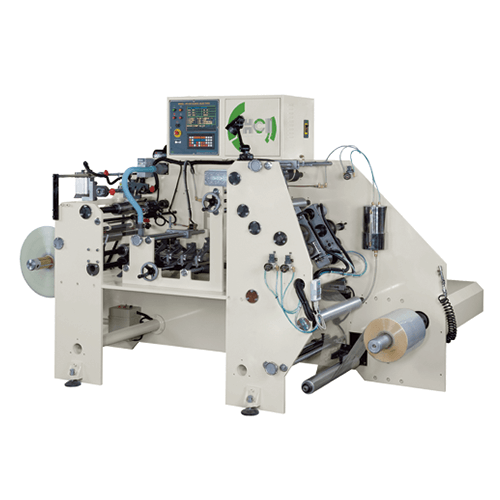

Product ID: FP-250

Designed for the center seaming operation of shrink sleeves such as PVC, PS, PET, and POF...

-

Unwinding Section

- Built with heavy-duty frame to ensure Shrink Sleeve Seaming Machine operation.

- Main drive AC motor + inverter.

- Cantilevered unwind 3" air shaft for fast roll changeover.

- Web guiding system provides the accuracy shrink sleeve seaming position.

- Equipped with magnetic powder brake for unwind tension control.

-

Shrink Sleeve Seaming Section

- Sleeve width adjusting device: forming plate unnecessary when shrink sleeve width over 50mm, bring down the production cost.

- Solvent flow adjusting system: the flow of solvent is automatically match up with the machine speed varies.

- Equipped with blower for drying the solvent faster also increasing the production speed.

-

Rewinding Section

- Cantilevered rewind 3" air shaft for fast roll changeover.

- Equipped with tension load cell assure extremely stable rewinding tension without the need to adjust it when speed and diameter varied.

- Equipped with statics eliminator.

-

Micro Computer Control System

- Adopted with industrial micro computer providing the accurate and stable control.

- Colorful LCD touch screen

- Unwind tension auto control function.

- Rewind tension auto increase function.

- Rewind length setting function.

-

Optional Accessories

- Shrink sleeve forming plate for under 50mm (Size on request)

- Hot melt coating device.

- Stroboscope with photo sensor.

- Vertical continuous perforation device.

- Twin line vertical continuous perforation device.

- Taping device.

- Rewind oscillation device

| Specifications | FP-250 Shrink Sleeve Seaming Machine |

| Material Width (mm) | 110 - 520 |

| Material Diameter (mm)(max.) | 500 |

| Unwind Core Inner Diameter (mm) | 76 / 3" |

| Tube Width (mm) | 50 - 250 |

| Rewind Diameter (mm) (max.) | 700 |

| Rewind Core Inner Diameter (mm) | 76 / 3" |

| Mechanical Speed (m/min.) | 0-200 |