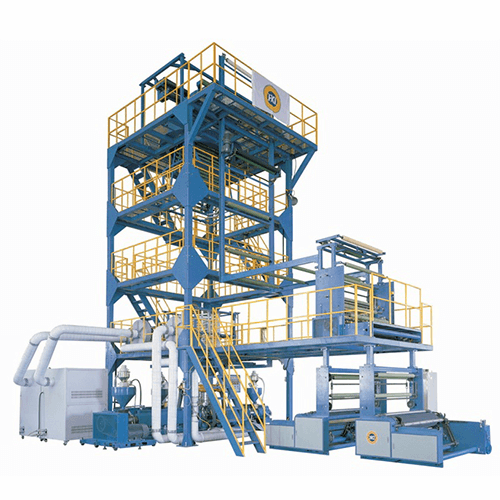

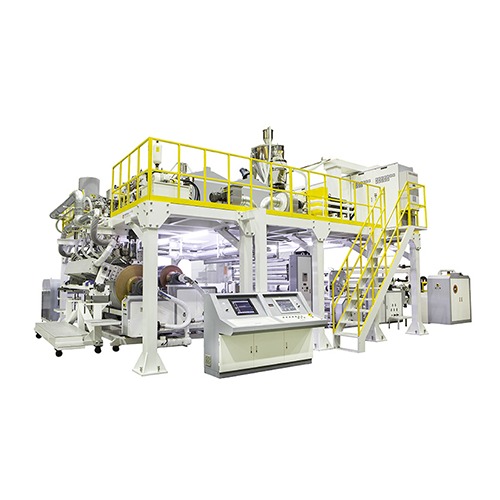

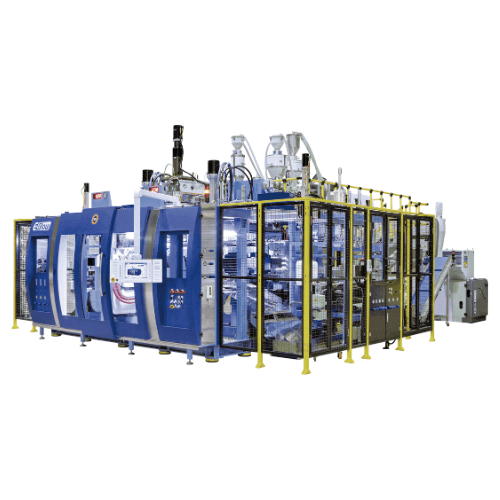

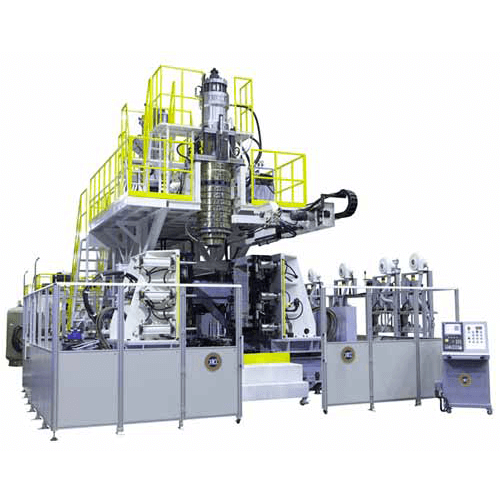

Classification : Continuous Extrusion Blow Molding Machines

Country:

Phone: 886-6-2532157

Fax: 886-6-2533079

Contact Person: Susan Wei

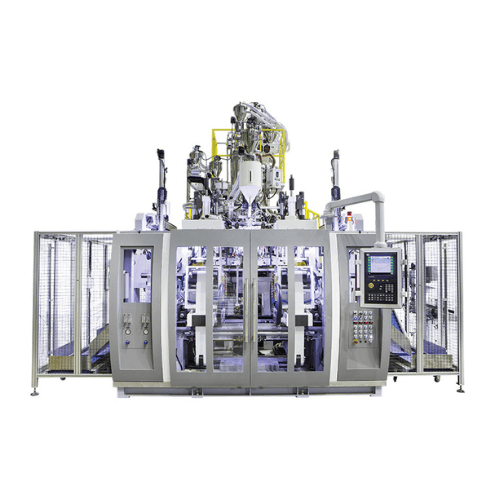

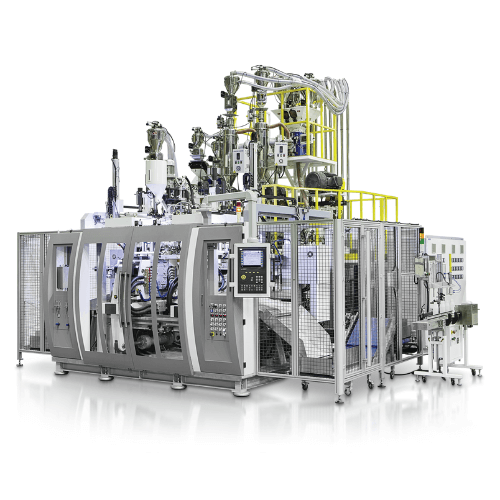

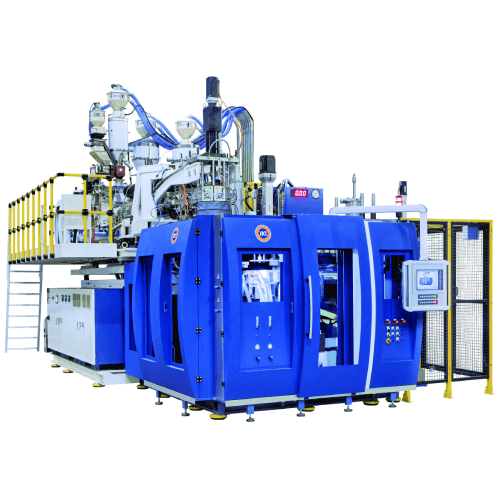

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle

Double Head, Double Station

HDPE bottle blow moulding machine

| Machine Model | FK/HBA-40/55G/30/30VT06DD |

| Product | 1-2lt bottle |

| Production | 400bph |

| Extruder | 40/55mm |

| Max. Extrusion Output | 100kg/hr |

| Head Design | 4 Layer, Double Head |

| Clamping Plate | 470x 450mm(HxW) |

| Clamp Force | 10tons |