● The narrowest injection seat design allows central distance adjustment of two injection seats according to requirement.

● The independent rotary table can accommodate all molds as long as their central distances fall within the application scope.

■ The rotary table with hidden hot and cold water paths allows neat configuration of mold water channels.

● The fixed mold platen module with movable central distance allows interchanging of different center distances.

● The maintenance personnel can perform troubleshooting through the Internet to rapidly grasp the machine status.

● Able to adapt dual-color molds in any central distances to reduce machine procurement costs.

● Full modular machine design with interchangeable plunger type and screw type injection unit.

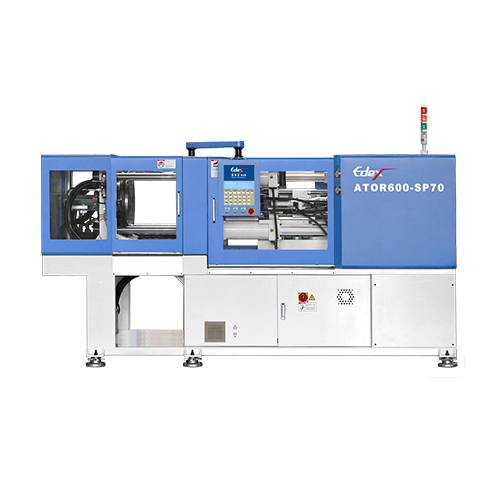

| Model | ATOR 600-SP70 | |||||||

| Injection | Screw diameter |

mm |

18 | 22 | ||||

| Plunger diameter |

mm |

12 | 16 | 16 | 20 | |||

| Injection volume |

cm3 |

13.5 | 24.1 | 24.1 | 37.6 | |||

| Injection pressure |

kgf/cm2 |

2591 | 2635 | 2635 | 2720 | |||

| Injection speed |

mm/s |

679 | 427 | 427 | 265 | |||

| Screw speed | RPM | 400 | ||||||

|

Clamping system |

Maximum clamping force |

KN / Tonf |

600 / 61.2 | |||||

| Distance between tie-bars |

mm |

410 X 360 | ||||||

|

Platen dimension |

mm |

580 X 630 | ||||||

| Max mold dimension | mm | 150 X 300 / 200 X 400 | ||||||

| Rotary table dimension | mm | 550 | ||||||

| Max. daylight |

mm |

550 | ||||||

| Minimum mold thickness |

mm |

150 | ||||||

| Bistance b/w nozzle | Tonf / mm |

150 ~ 200 |

||||||

| Ejector stroke |

Tonf / mm |

2.13 X 2 / 100 | ||||||

| Heater zone |

set |

N3 + H3 / N3 +H3 | ||||||

| Heater capacity |

KW |

4 + 4 | ||||||

| Electric power |

KW |

10 + 10 | ||||||

| Machine dimension |

m (LxWxH) |

3.75 X 1.16 X 1.54 | ||||||

| Machine weight | Ton | 4.1 | ||||||