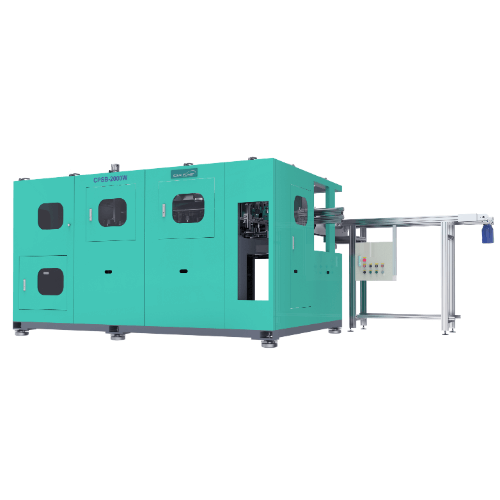

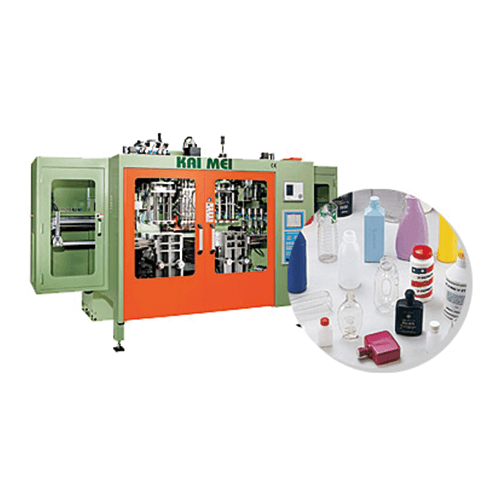

Classification : Blow Molding Machines

Applications:

Food & Beverage Related Products

All Kinds of Bottles & Containers

Lifestyle & Cosmetics

Packaging

Medical Equipments

Kettles

Juice Bottles

Milk Bottles

Lubricant Bottles

Plastic Bottles

Roll On Bottles

Cosmetic Bottles

Medical Packaging

Saline Solution Bottles

Intravenous Drip Bottles

Water / Tea Bottles

Transparent Food Containers

Yogurt Bottles

Country: Taiwan

Phone: 886-6-2795551

Fax: 886-6-2795553

Contact Person: Mr. Michael Chen

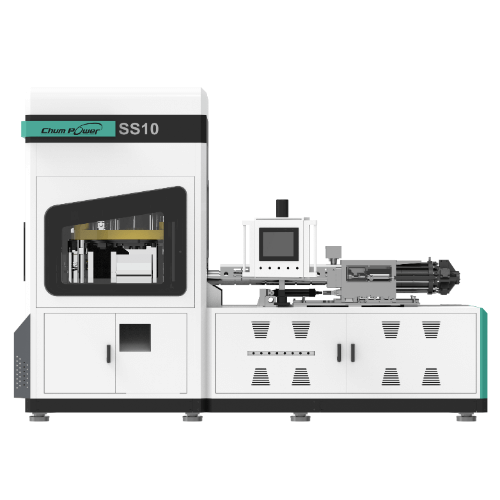

- Injection Unit: Central force in-line screw plasticizing injection unit

- Clamping Unit: Twin cylinder with pressure booster ram system enables fast clamping, low-pressure safety detection, and fast pressure boosting.

-

Core Mold: With two-station, 180-degree rotary unit.

- Precision hydraulic system makes the mold clamping motion noiseless.

- The core mold is designed with 180-degree horizontally rotating apparatus. The mold can stop at both operational side and rear side of it, which makes its maintenance and detachment works convenient.

- Hydraulic Unit: Proportional Electro-Hydraulic Relief & Flow Control System is used to control pressure and flow. It is easy to operate and very sensitive.

- PLC Programmable Control Unit: Human Machine Interface (HMI) is used as a central control unit in the Single Stage Blow Molding machine (IB Series).

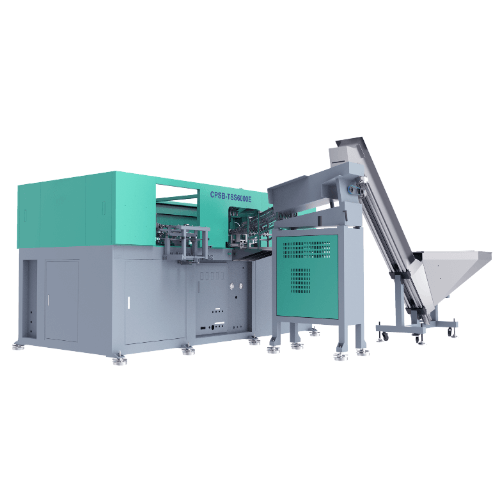

APPLICATION:

PS/PE Beverage Bottles

HIPS Yogurt bottles

PET/PS/PP/PE Cosmetic containers

PPSU/PA/PP/PC Feeding bottles

PC/PMMA Lamp shades

PC LED globes LED

PP/PE/PET Medical containers

TRITAN/PC Sports bottles

PET/PS/PP/PE Cosmetic containers

PET Others bottle

PET/PP/PE Others bottle

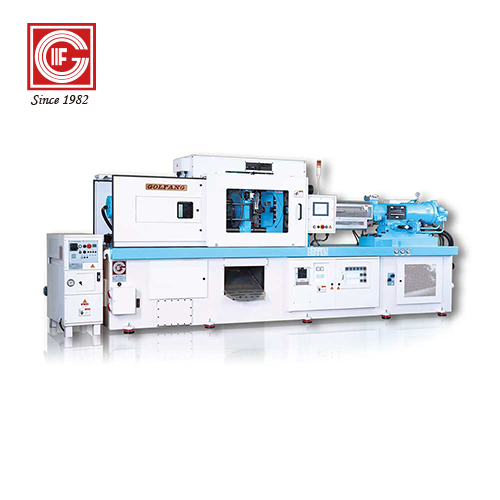

● The mechanical design is based on the blueprint of the general-purpose injection molding machine. Simply with the fundamental knowledge about injection molding machine, any technician can competently operate and maintain Golfang’s machine.

● The equipment price is reasonable, which lowers customer’s investment cost on machines and molds while increasing production and marketing competitiveness simultaneously.

● Horizontal machine makes operation and maintenance ergonomically sound, and provides great human-machine interaction.

● The mold design adopts the method of common mold base. Simply with the change of mold part, the shape, weight, or even the length of the product can be manipulated. Such mechanical feature saves producers plenty of time on mold alignment and lessens expensive hiring of great expertise on mold changeover. It reduces the mold cost and thus enhances the advantages of competitiveness on orders that meets the present marketing demands for high multiplicity yet low monotony on manufacturing applications.

● The machine is most suitable for manufacturing high quality and top standard products, such as baby feeding bottles and cosmetic containers which finished products feature smooth-even mouth, great sealing, round and smooth body and bottom, superior quality, and no seam mark.

● A great variety of resins are applicable for a comprehensive production, which including: PC PP PE PS AS PMMA PET PETG TRITAN TPR PES PPSU PA K-Resin.

● The equipment price is reasonable, which lowers customer’s investment cost on machines and molds while increasing production and marketing competitiveness simultaneously.

● Horizontal machine makes operation and maintenance ergonomically sound, and provides great human-machine interaction.

● The mold design adopts the method of common mold base. Simply with the change of mold part, the shape, weight, or even the length of the product can be manipulated. Such mechanical feature saves producers plenty of time on mold alignment and lessens expensive hiring of great expertise on mold changeover. It reduces the mold cost and thus enhances the advantages of competitiveness on orders that meets the present marketing demands for high multiplicity yet low monotony on manufacturing applications.

● The machine is most suitable for manufacturing high quality and top standard products, such as baby feeding bottles and cosmetic containers which finished products feature smooth-even mouth, great sealing, round and smooth body and bottom, superior quality, and no seam mark.

● A great variety of resins are applicable for a comprehensive production, which including: PC PP PE PS AS PMMA PET PETG TRITAN TPR PES PPSU PA K-Resin.

|

MODEL NO.

|

UNIT |

GF/IB-100

|

GF/IB-140

|

GF/IB-170

|

||||||

|

INJECTION - INLINE SCREW

|

||||||||||

|

I06

|

I08

|

I10

|

||||||||

| Screw Dia. | mm |

40

|

42

|

45

|

45

|

50

|

55

|

60

|

65

|

70

|

| Inj. Capacity | cm3 |

135

|

150

|

170

|

250

|

300

|

365

|

600

|

700

|

800

|

| Inj. Pressure | kg/cm2 |

1715

|

1555

|

1355

|

1880

|

1520

|

1260

|

1555

|

1320

|

1140

|

| Inj. Rate | cm3/sec |

115

|

125

|

145

|

132

|

165

|

200

|

185

|

220

|

250

|

| Screw Revolving Speed | R.P.M. |

25 - 200

|

20 - 190

|

20 – 160

|

||||||

| Nozzel Sealing Force | tons |

4

|

4.3

|

4.3

|

||||||

| Heater | kw |

8.5

|

17.2

|

19.2

|

||||||

|

CLAMPING-PRESSURE BOOSTER RAM SYSTEM

|

||||||||||

| Clamping Force | tons |

100

|

140

|

170

|

||||||

| Die Open Force | tons |

10

|

10

|

10

|

||||||

| Space Between Tie Bars | H.V.(mm) |

370 x 430

|

470 x 600

|

740 x 540

|

||||||

| Platen Dimension | H-V (mm) |

570 x 640

|

710 x 840

|

1030 x 830

|

||||||

| Clamping Stroke | mm |

475

|

575

|

1000

|

||||||

|

CORE UNIT

|

||||||||||

| Number of Stations | - |

2

|

2

|

2

|

||||||

|

BLOW UNIT

|

||||||||||

| Work Pressure | kg/cm2 |

210

|

210

|

210

|

||||||

| Pump Output | l/min |

105

|

135

|

150

|

||||||

| Pump Drive Motor | HP |

30

|

40

|

50

|

||||||

| Oil Tank Cap. | l |

530

|

725

|

1000

|

||||||

| Comp. Air | kg/cm2 |

8 - 35

|

8 - 35

|

8 - 35

|

||||||

|

MACHINE DIMENSION

|

||||||||||

| Overall Dimension | Meter |

5.3x1.3x2.8

|

6.2x1.42x2.9

|

8x1.8x3.4

|

||||||

| Weight of Machine | tons |

7.3

|

11

|

18.2

|

||||||

|

POWER REQUIREMENT

|

||||||||||

| Cooling Water (UNDER 25oC) | Kcal/hr |

10,000

|

15,000

|

19,000

|

||||||

| Chilled Water (UNDER 10oC) | Kcal/hr |

7,000

|

10,000

|

15,000

|

||||||

| Air Compressor | l/min |

250

|

300

|

500

|

||||||

| Power Supply | kw |

30

|

45

|

60

|

||||||

※Golfang reserves the right to change above specification according to the product requirements.