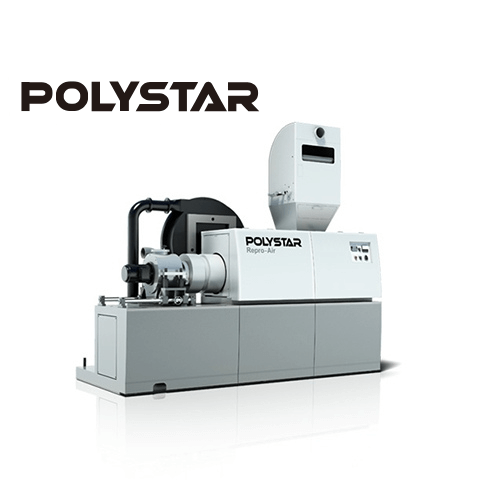

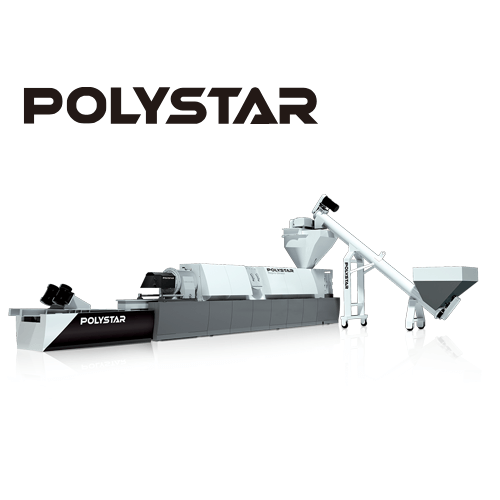

Recycling machine designed for processing up to 95% printed surface material

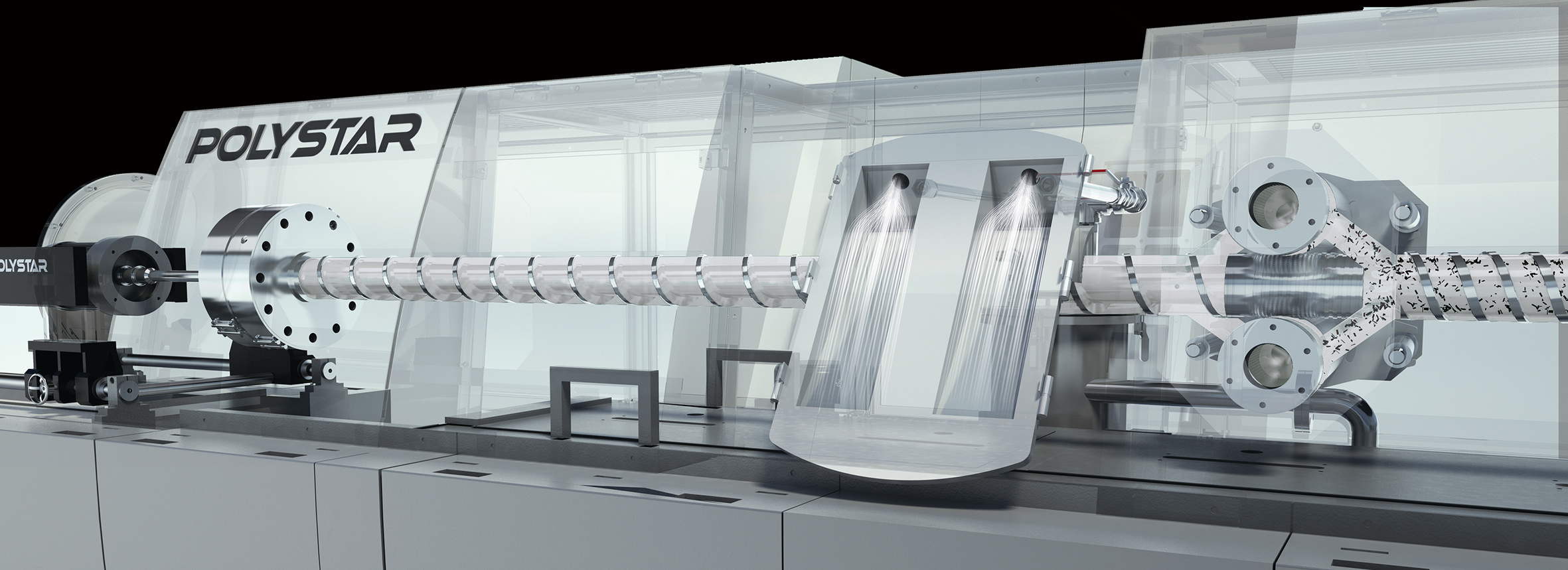

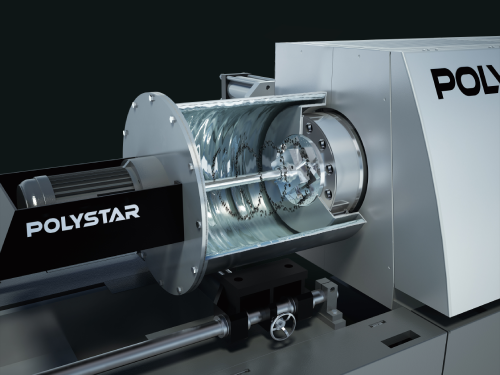

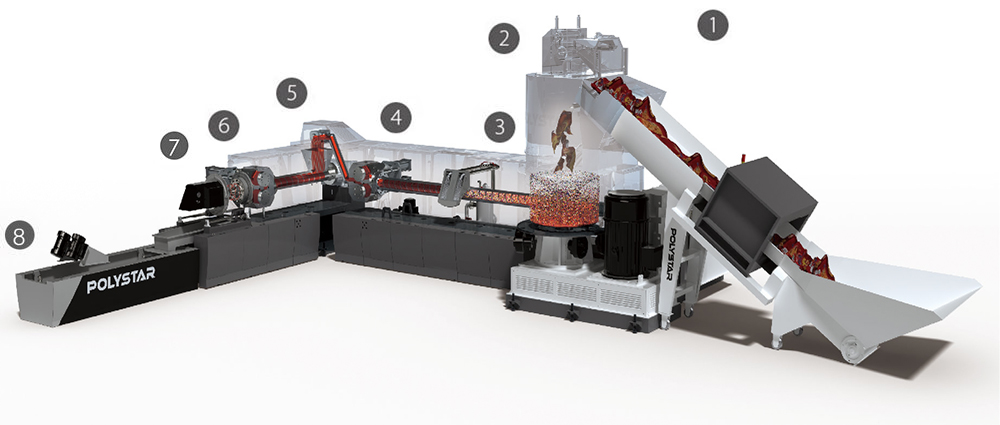

1. Filter re-positioning: before degassing.

2. Triple degassing.

In addition to the double degassing in the first extruder, the venting area (the connection between the first and second extruder) serves as a third degassing section to further remove the ink and extra humidity level from the material.

3. 10% less power consumption; 20% higher output; 100% pellets re-usability.

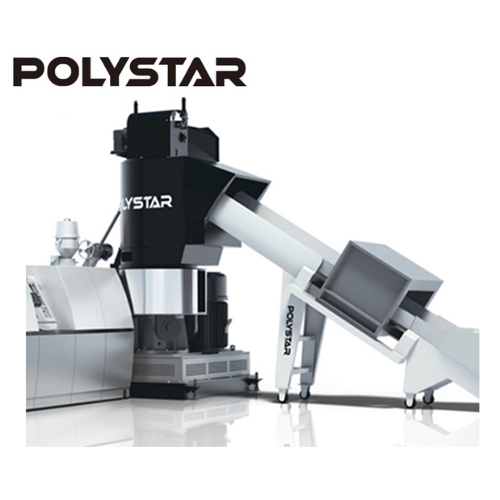

Improved cutter-compactor for faster and more stable feeding.

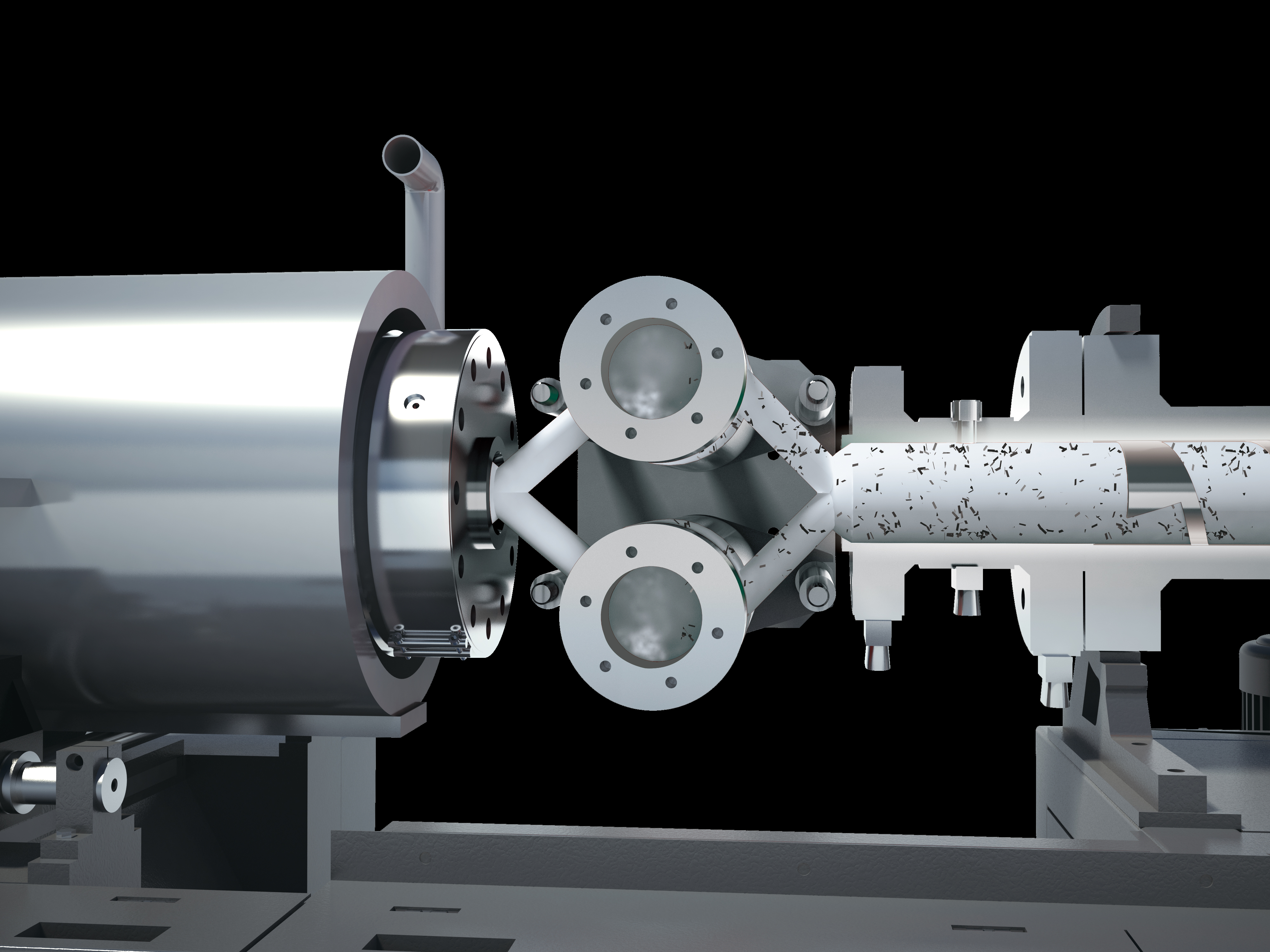

4. Non-Stop dual channel piston filtration system

- Filter with dual channel system for non-stop operation and reduces machine down time

5. Automation Die face pelletizing technology for uniform pellets producing

- Produces high quality plastic pellets for reprocessing

6. Intelligent pressure detection and alarm control system

7. Elegant industrial design

8. Polystar Machinery is able to customize each section of machinery regarding to customer's need.

- Shape: Packaging Film, bags, sheet, net, foam, tapes, PP Woven/ Raffia, Plastic, Regrind, flakes, granules, scraps, edge trimmed, wash film flakes

- Type: HDPE,LDPE,LLDPE, PP, BOPP. ABS, CPP, OPP, PA,PC,PS,PU,EPS,EPE, TPO

Foam roll

Foam sheet

Food container

Net, cover

Waste films

printed film rolls

Printed waste bags

Waste films

Printed Shrink Film

Garbage bag

Agricultural film

Humid Construction

Printed Multilayer film

Printed Bubble film

BOPP film

HDPE/PP Fabric

PE/PP printed film rolls

Humid prewashed flakes

Printed Food packaging

Humid Swimming pool covers

- 100% pellets re-usability right back into your production line

- Minimal material degradation without property change

- Reducing production cost by reprocessing your own industrial waste

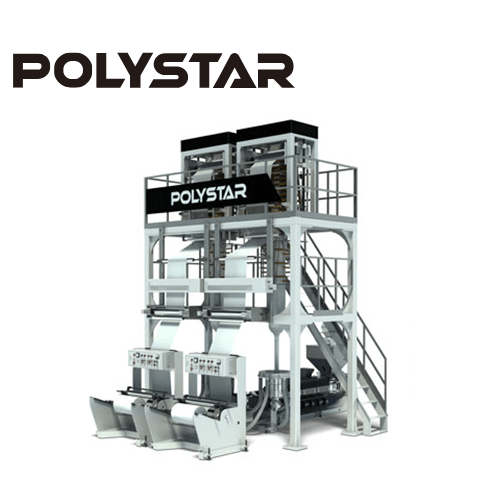

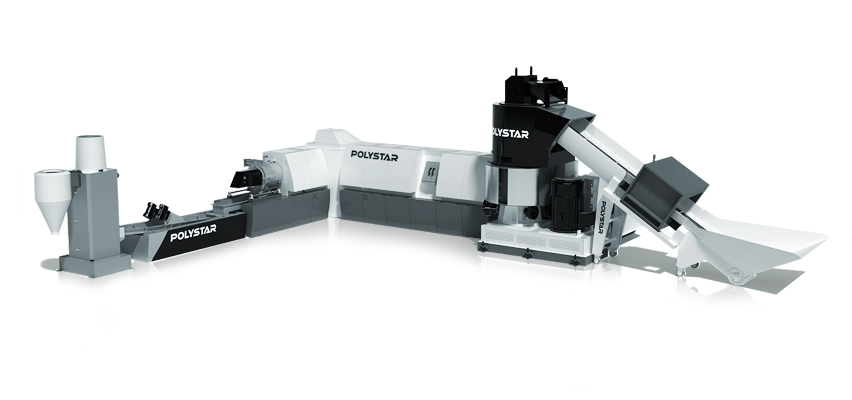

1. Belt Conveyor Feeding

- With belt conveyor: Feeding of scraps is easy and automatically controlled

1. Nip Roller Feeding

- With nip roll: film-on-rolls can be fed at the same time.

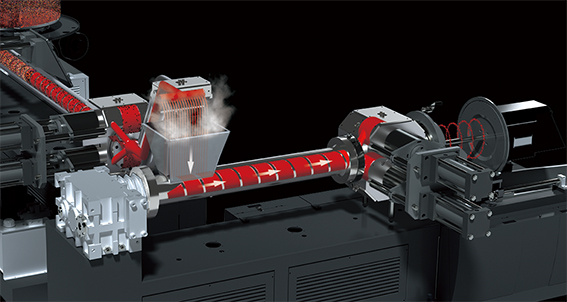

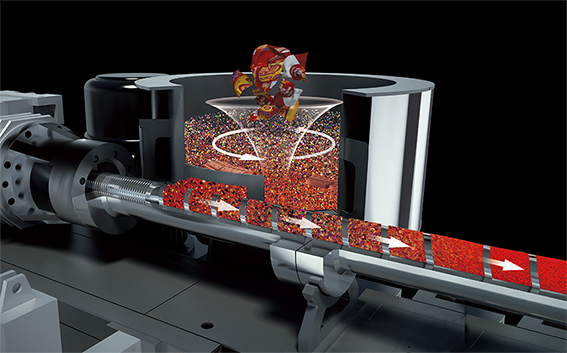

2. Cutting and Compacting

- Cutter compactor with rotary knives & direct feeding to extruder: Cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3. Degassing

- Two-zone degassing (double-vented degasification): Able to process films with larger printed area and some water content.

4. Filtration

- Screen change with dual channel system :

For non-stop operation and prevents material from leaking.

5. Third Degassing

- In addition to the double degassing in the first extruder, the venting area (the connection between the first and second extruder) serves as a third degassing section to further remove the ink and extra humidity level from the material.

6. Second Filtration

- The extra filtration on the second extruder ensures better pellet quality. Therefore, giving more stable production when re-used again in production lines.

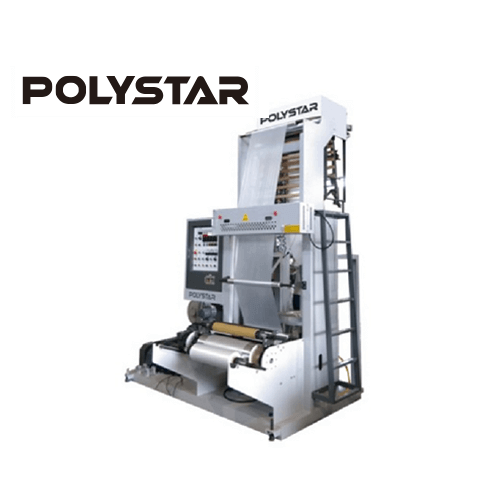

7. Die Face Pelletizing

-

Automatic pelletizing speed adjustment: Produces more uniform-sized pellets without labor intervention.

-

Automatic blade pressure adjustment: Less machine downtime, easier to change and adjust knife.

8. Recycled Pellets

- The recycled plastic pellets can be put directly back into the production line such as blown film extrusion and pipe extrusion and injection molding.

| Model Name | Repro-Flex Plus |

| Final Product | Plastic pellets/granule |

| Machine Components | Conveyor belt, cutter compactor shredder, extruder, pelletizing unit, water cooling unit, drying unit, silo tank |

| Recycling Material | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Output range | 80~1100 kgs/hr *Based on post-industrial LDPE film clean, dry |

| Feeding | Conveyor belt (Standard), Nip roll feeder (Optional) |

| Screw Diameter | 65~180mm (customized) |

| Screw L/D | 30/1,32/1,34/1,36/1 (customized) |

| Screw Material | SACM-645 |

| Degassing | Double vented or triple degassing (customized) |

| Cutting Type | Hot die face pelletizing |

| Cooling | Water cooled |

| Voltage | Customized |

| Optional Devices | Metal detector(S+S) , Nip roller for film roll feeding , Additive feeder for masterbatch, Centrifuge dryer for drying |

| Delivery Time | 75~120 days |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

Output:

80~100 kgs/hr

Screw diameter: 65mm

HNT-65VS

Output:

120~200 kgs/hr

Screw diameter: 85mm

HNT-85VS

Output:

200~300 kgs/hr

Screw diameter: 100mm

HNT-100VS

Output:

300~450 kgs/hr

Screw diameter: 120mm

HNT-120VS

Output:

450~700 kgs/hr

Screw diameter: 150mm

HNT-150VS

Output:

700~900 kgs/hr

Screw diameter: 165mm

HNT-165VS

Output:

900~1100 kgs/hr

Screw diameter: 180mm

HNT-180VS

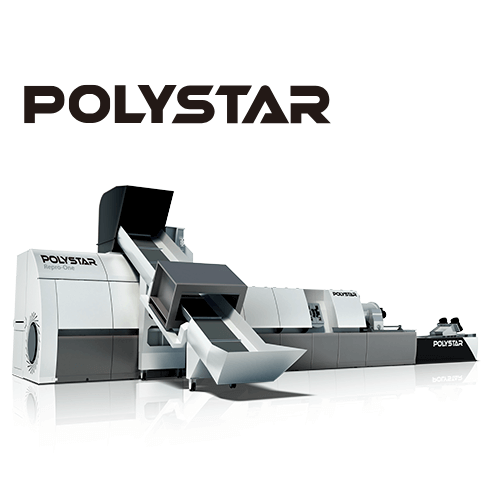

Post-consumer recycling is growing in Russia and Polystar has been supplying to this market since 2012

Post-consumer recycling requires several processing steps such as sorting (material separation), size reduction, washing, drying and pelletizing in order to achieve good quality recycled pellets as the end product.

Good degassing and filtration are probably the most important processes in pelletizing machines when it comes to post-consumer recycling. In many occasions, a two-stage recycling pelletizing machine is preferred by professional recyclers who focus on post-consumer recycling.

The washed material is fed into the compactor for a quick densifying process (which at the same time further dries the material by natural heat and friction); this helps to stabilize the material feeding into the extruder. The material then goes into the first (main) extruder for the filtration process and a two-vented degassing (installed with high efficiency vacuum system). The material then passes through an open area for the third and final degassing, and enters the second stage (short) extruder where the second filtering process is done.

The two-stage pelletizing line significantly improves the quality of the recycled pellets as the washed material goes through two filtration and three degassing steps in both extruders combined. As a result, the final pelletizing process becomes more stable and easier to operate because the material is already well prepared and pre-conditioned.

A post-consumer recycler located in Belgorod, Russia who is dedicated in the recycling of municipal waste has a complete set up: The automatic sorting lines initially separate paper, glass, metal and plastic. The plastics are then separated by groups: PET bottles; films of HDPE and LDPE; and rigid plastic and followed by two washing lines - one for PET bottle and another for plastic films. After washing and drying the process is completed in the POLYSTAR pelletizing recycling machine. The recycled pellets are mainly used for producing plastic boxes for vegetables.

To date, in Russia 68 sets of Polystar plastic pelletizing machines have been installed since 2012. Of these machines, 45 lines are dedicated specially for post-consumer recycling.

Source:Plastics News Asia

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication

Fast online trouble shooting