Productive. Flexibility.

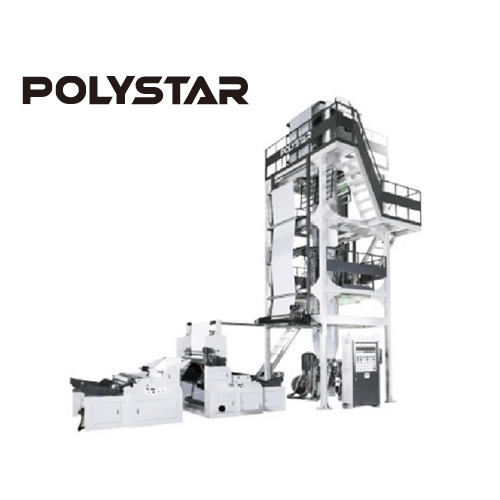

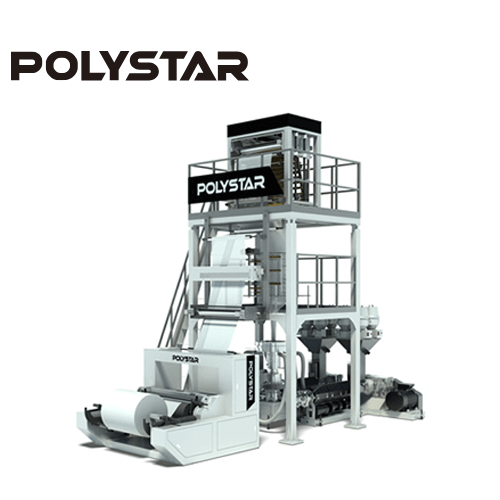

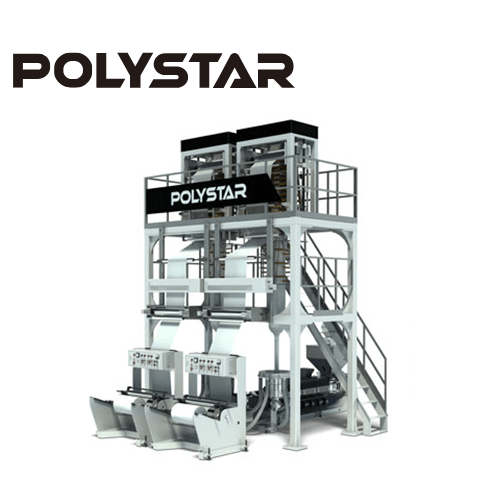

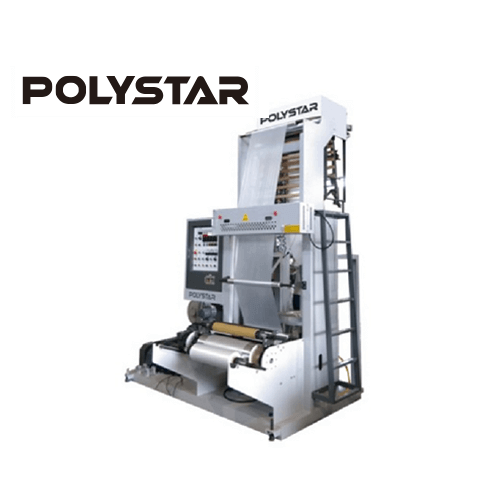

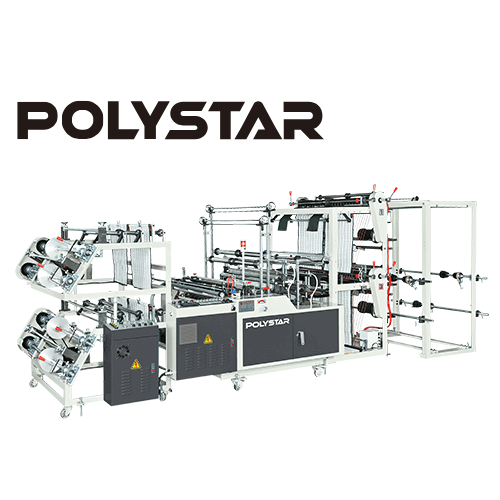

AB Two-layer blown film machines produce two-layer films by combining and co-extruding materials from two extruders through a die. The die-head design ensures good color separation on each layer. This machine is used to produce a wide variety of films, including agricultural films, food packaging films, industrial packaging films, consumer packaging films, and medical and pharmaceutical packaging films.

Advantages of Two Layer AB Blown Film Machine

More Durable

Two-layer films can be designed to block oxygen and moisture, keeping the contents of the package fresh and protected.

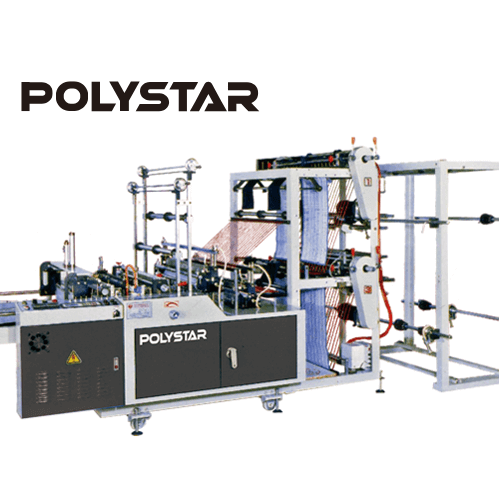

Two Sides with Different Colors

For similar reasons, producers who make bags of 2 colors or use many different formulas (mixed with recycled materials and calcium carbonate from different sources) for various product specifications find it efficient and easy to use this blown film co-extrusion.

| Model Name | Bi-X Co-extrusion |

| Final Product | HDPE, LDPE, LLDPE Plastic Film |

| Application | Mulch film, agricultural film, flexible packaging film |

| Material used | HDPE, LDPE, LLDPE virgin raw material, recycled material, CaCO3 compound, biodegradable material, masterbatch and additives |

| Output range | 45~200kg/hr (depends on extruder size) |

| Film Layer | Multilayer - Two layer |

| Screw Diameter | 45-80m (customized) |

| Screw L/D | 28/1,30/1 (customized) |

| Screw Material | SACM-645 or bimetallic |

| Width | 650~1800mm |

| Thickness | 10-100 micron |

| Optional Devices | Auto loader, masterbatch dosing system, rotary die head, bubble controller, corona treater, embossing roller, automatic winder, double winder |

| Delivery Time | 100~120 days |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

| Model | CE-AB-45/45 | CE-AB-55/55 | CE-AB-65/65 | CE-AB-80/80 |

| Screw diameter | 45mm+45mm | 55mm+55mm | 65mm+65mm | 80mm+80mm |

| Max. width | 650mm | 1000mm | 1500mm | 1800mm |

| Output | 45~55 kg/hr | 80~90 kg/hr | 130~150 kg/hr | 160~200 kg/hr |

| Thickness | 0.01~0.1mm | 0.01~0.1mm | 0.01~0.1mm | 0.01~0.1mm |