Lower moisture, higher capacity

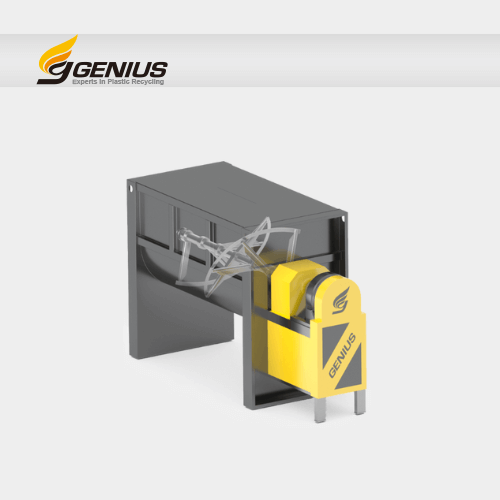

Plastic squeeze dryer is a vital part of plastic film washing line.

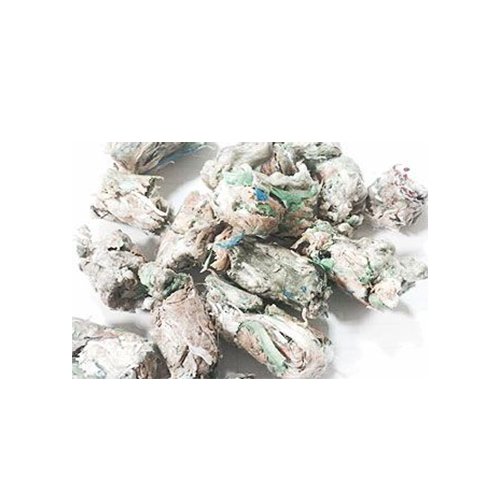

Washed films retain up to 30% wetness normally. High humidity will be affecting the efficiency and production of the following pelletizing process. Having a plastic squeeze dryer is a must to dehydrate the washed film, reduce the volume of recycled materials and further refine the essence of final plastic pellets.

Final moisture less than 1% ↓ after processed.

| Model | DW-250 | DW-300 | DW-350 | DW-380 |

| Main Drive | 56.25KW | 93.75KW | 131KW | 187.5KW |

| Screw Diameter | Φ250mm | Φ300mm | Φ350mm | Φ380mm |

| Capacity | PE : 250~350kg/hr | PE : 450~650kg/hr | PE : 700~900kg/hr | PE : 1000~1200kg/hr |

| PP : 150~250kg/hr | PP : 350~450kg/hr | PP : 500~700kg/hr | PP : 700~900kg/hr |

All of our products can be customized according to customer requirements.

Even the water-washed plastic film via procedures of spin dryer still contains over 10% moisture whose material would reduce productivity of extruder and quality of pellets. The latest development for recycling film: plastic film squeeze dryer which could make moisture to the minimum and the squeezed material only contains 3% moisture below.

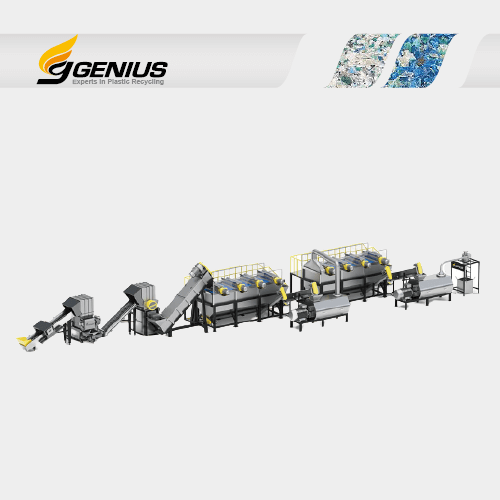

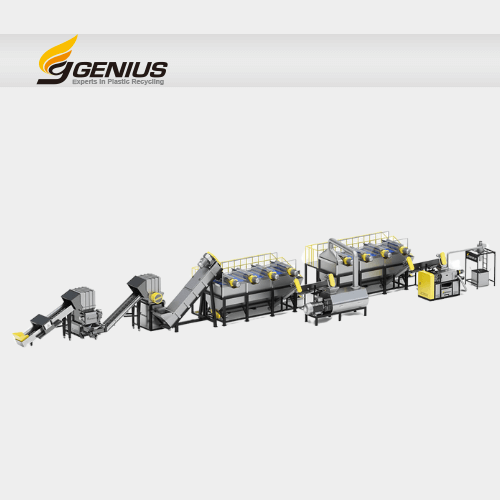

Agricultural Film Recycling Machine

Stretch Film Recycling Machine

Woven Bag Recycling Machine

Japan Subsidy Policy Assisting the Growth of Genius’ Squeeze Dryers

![]()

Japan generates about 9.03 million tons of plastic waste per year, and is the second largest plastics user in the world, second only to the United States. Faced with such a large amount of plastic waste, Japan’s waste recycling technology is quite refined (with about 80% recycling rate).

In recent years, the Ministry of the Environment of Japan has proposed a container recycling subsidy policy to encourage domestic industries to recycle plastic waste, thereby enhancing Japan’s position in the circular economy. Moreover, Genius’s squeeze dryer sales have grown significantly in the Japanese market in 2019. As of October, it had successfully sold 15 units.

Thanks to its user-friendly design, excellent performance and splendid production capacity, Genius’s smart recycling production line has been well received in 20 countries, including Japan,. Through the global sales network set up by local agents, Genius provides premium and reliable services to its clients.

Genius’s plastic recycling production line is entrusted to its Japanese agent “Pelletizing Technology Co., Ltd. (造粒技術株式會社)”. The person in charge, Bill Kobayashi (小林哲樹), has a background in machinery industry, and is familiar with Japanese manufacturing industry trends, as well as the country’s relevant regulations. He is well equipped in solving a whole variety of questions that customers may have regarding the production process and Genius’ products, thereby facilitating Genius’s sales performance in Japan.

Peter, Genius’ representative stated: “Japan places great emphasis on word-of-mouth marketing, and through the matching of local professional agents, Genius’s collaboration with customers can be accelerated. So far, Genius has worked with Mr. Bill Kobayashi for over 5 years, facilitating a win-win situation for both parties as well as their customers”.

DW-300 / PLASTIC SQUEEZE DRYER / LDPE FILM / ROMANIA

Currently, Genius Corporation has installed DW-300 squeeze dryer in Romania.

Even the water-washed plastic film via procedures of spin dryer still contains over 10% moisture whose material would reduce productivity of extruder and quality of pellets.

The latest development for recycling film: plastic film squeeze dryer which could make moisture to the minimum and the squeezed material only contains 3% moisture below.

This increases productivity of extruder and quality of recycled pellets. Hence; the biggest plastic corporation from Romania purchased the first plastic film squeeze dryer which will surely bring benefits and business.

DW-350 / PLASTIC SQUEEZE DRYER / WASHED PE FILM / SOUTH AFRICA

Plastic film screw press dryer is one of our best sellers. Squeezing process is one of the key factors in the efficiency of plastic extruders. The films produced by our plastic squeezer retain less moisture by 1% to 3%, so that with the utilization of plastic film screw press dryer will improve the quality of pellets significantly.

“The dryers where made to such a good standard .wanted to see if it's in all the machines you make. looking forward to coming to the next show so we can spend some time together” the owner of the company said.

The client’s feedback signifies the benefits of our product. High standard product quality, professional design team and advanced processing technology are essential to the success of our plastic film screw press dryer.