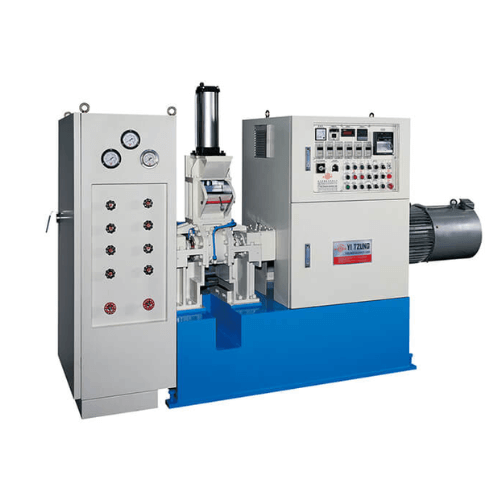

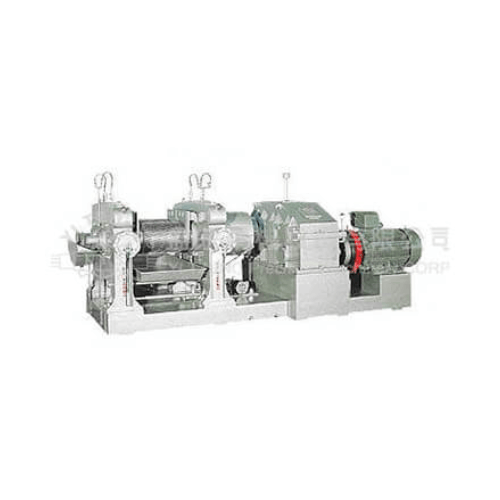

Basically,rubber material is very easy to be mixed with many impurities during mixing processes.No doubt,because of this harmful factor,it can easily cause the follow-up products to result in many defects. But now this innovative design machine can solve this annoying problem efficiently.

It not only utilizes the Twin Taper Screw Device to squeeze rubber mixing material into the Single Screw Filter Device effectively but also uses the rotation power to push the mixing material into the die heas and also through the filter net to get rid of the impurities completely. After that,the mixing material can be squeezed out from the compression die to pre-formating.

As a result,this new innovative machine can fix the quantity,and conse-quently obtain an excellent reputation in several industry fields such as Oil seal,O-ring,EVA,Tyre and so on.

- Purity degree of mixing material is keept stable at the high level.

- Saves Manpower;Saves Time;Saves Energy.

- Continued Automatic Porduction;High Volume of Desorption;High Productivity.

- Unique design of the taper screw and extrusion chamber that provide excellent conditions so rubber material can twist in one time to avoid residue and material waste.

- Excellent cooling system that can ensure keeping the substance and the quality of material stable.

- Easy and Simple to Clean and Maintain Machine to Extend machine’s life.

| Model | Applicable Dispersion Kneader | Applicable Intensive Mixer | Twin Taper Screw Device | Single Screw Device | |||

|---|---|---|---|---|---|---|---|

| Motor (DC) | R.P.M. | Motor (DC) | R.P.M. | Screw Diameter (MM) | |||

| TR150 | YK75,YK110 | IM50,IM75 | 60HP | 2.6~26 | 75~100HP | 4.5~45 | 150 |

| TR200 | YK75,YK110 | IM75 | 60HP | 2.6~26 | 125~150HP | 4.5~45 | 200 |

| TR250 | YK110,YK150 | IM75,IM100 | 60HP | 2.6~26 | 175~200HP | 4.5~45 | 250 |