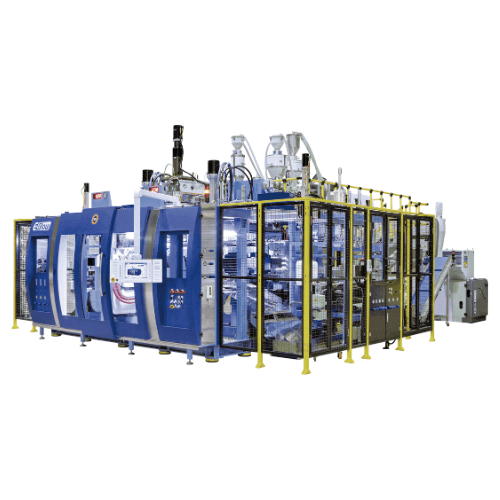

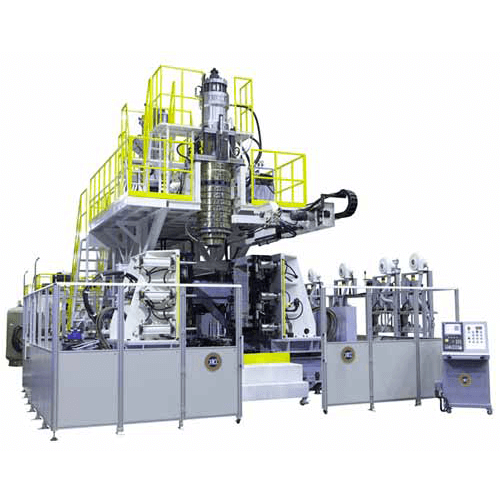

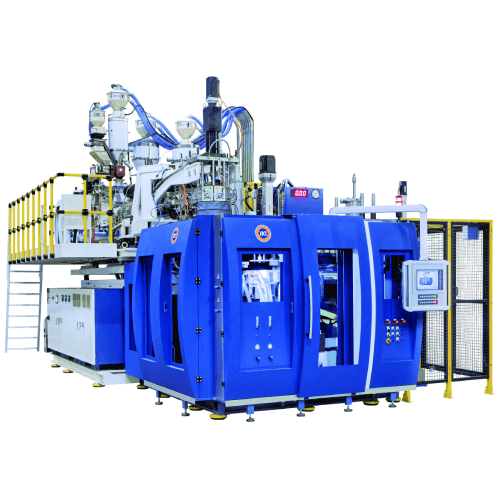

Classification : Continuous Extrusion Blow Molding Machines

Country:

Phone: 886-6-2532157

Fax: 886-6-2533079

Contact Person: Susan Wei

Mono Layer Bottom Blow Moulding Machine for 20lt~30lt jerry can

Single Head, Single Station

| Machine Model | FK/HBB-75GVT30SS |

| Product | 20/25lt Jerry Can |

| Production Rate | 120bph |

| Extruder | 75mm |

| Max. Extrusion Output | 170kg/hr |

| Head Design | Single head |

| Clamping Plate | 720x550mm( H x W ) |

| Clamp Force | 30tons |