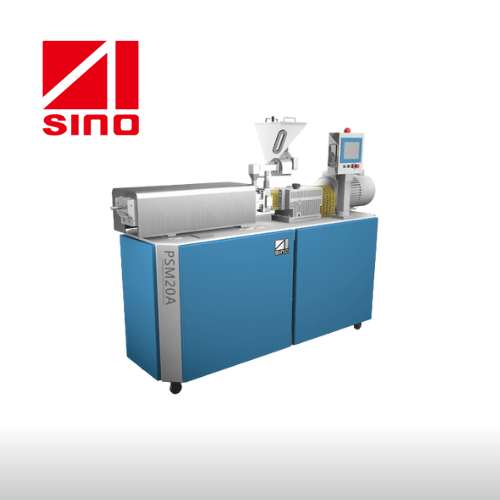

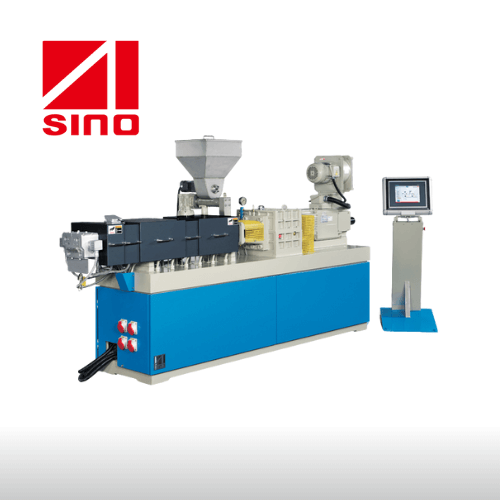

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

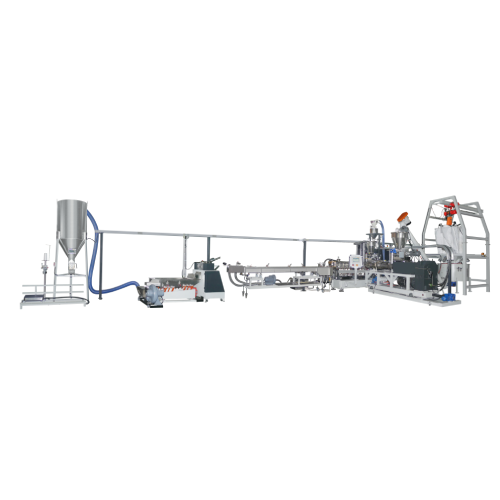

Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

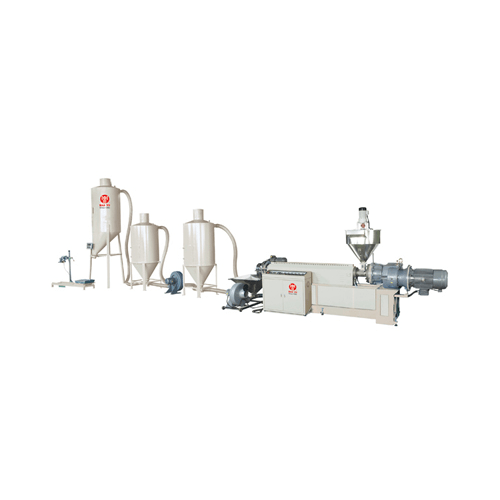

Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

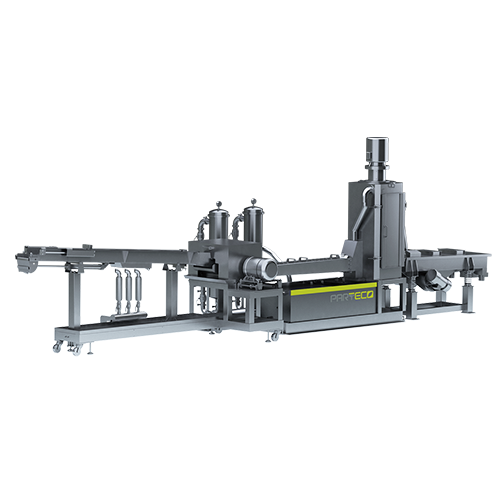

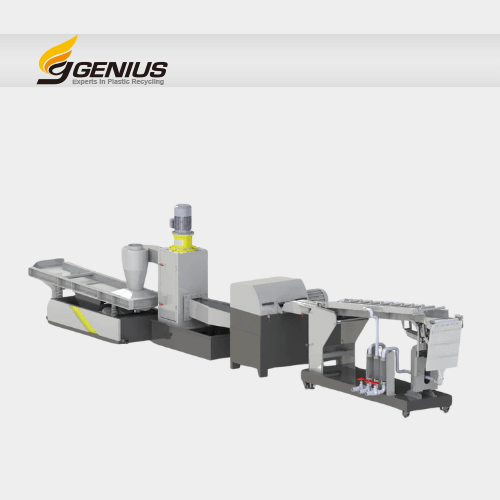

Automatic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediately while cooling at the same time. No more drawing strands before pelletizing. Minimize the lump waste during drawing the strands. GENIUS

Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Minimize The Powder Waste Suitable for higher MI or sticky materials. Production line is equipped with high-precision pellets cutter and specially designed vibrating screener.

Air Cooled Mini Plastic Recycling Machine - Piranha Series

Categories : Plastic Pelletizer Machines

Auto pellet length control via motor load to keep pellet length constant Low temperature heat soak feature - 20 minutes to soak prior to starting To build perfect granules in real-time Full access to dicer and safe access to blade changing Air cooled pelletizer Dual geometry low L/D ratio screws, manufactured from SACM-645, nitride hardened, ground and polished Barrels are manufactured from SACM-645, honed finish and nitride hardened Cold start protection No material shutdown

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

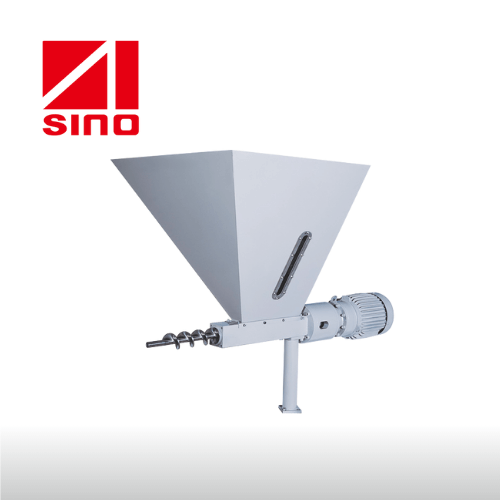

Single Screw Feeder-PSA

Categories : Feeders

The PSA series single-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSA single-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Options include standard double-flight, single-flight, T-type, and spring type screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

Water-Cooled Type PVC Pelletizer

Categories : Plastic Pelletizer Machines

Water-Cooled Type PVC Pelletizer, wpc pelletizing machine.

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Compounding Lines

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materials Knead well Die-face cutting Adequate kneading