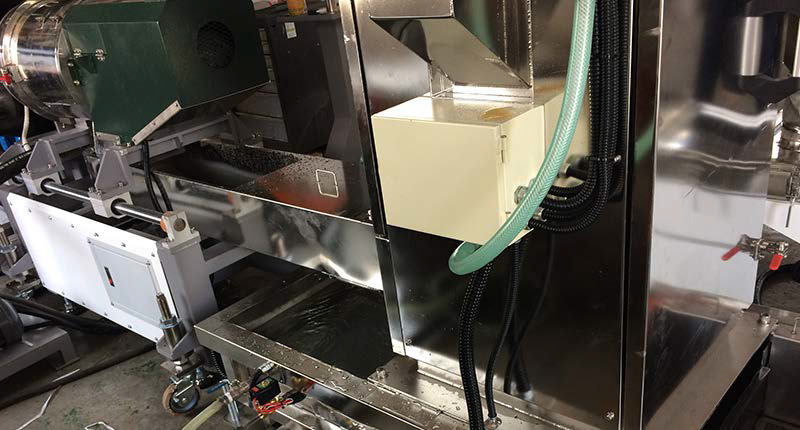

INTEGRATES SHREDDING, EXTRUDING AND PELLETIZING INTO ONE MACHINE

- The integrated cutter helps compact the material to reduce its volume and increase its density. This process aids in preheating, mixing, and drying the material, preparing it for further processing and recycling.

- High productivity, low noise.

- Preheating the raw material can enhance the production efficiency of the extruder. Compared to traditional crusher , it produces less noise and has a capacity that exceeds traditional models by more than double.

- Integrating multiple functions into one machine simplifies maintenance and upkeep by centralizing these tasks. It also saves space within the factory layout.

- Two stages extruder with ventilation holes, providing three stages of venting.This is a standard feature of GEORDING. The design of the ventilation holes helps to prevent the formation of bubbles or excessive internal pressure during the extrusion process, thereby improving product quality.

- Two stages extruder offers higher filtration efficiency.With two-stage filtering process. This effectively removes impurities from the raw material, reducing contaminants, thereby improving the quality and consistency of the final product. Additionally, it helps minimize wear and blockage in the extruder, extending the extruder lifetime.

|

Model |

GD-85TS-3IN1 |

GD-100TS-3IN1 |

GD-120TS-3IN1 |

GD-150TS-3IN1 |

GD-175TS-3IN1 |

|

Shredder |

|||||

|

Conveyor |

1HP*4000(L)*400(W) |

2HP*6000(L)*600(W) |

2HP*6000(L)*800(W) |

2HP*6000(L)*800(W) |

2HP*6000(L)*800(W) |

|

Size |

Ø760 mm |

Ø1000 mm |

Ø1000~1500 mm |

Ø1000~1800 mm |

Ø1000~2000 mm |

|

Motor |

40HP |

75HP |

100HP |

125HP |

150HP |

|

Main Extruder |

|||||

|

Screw Diameter L/D Ratio |

32 |

36 |

36 |

36 |

36 |

|

Main Power |

50~75HP |

125~150HP |

150~250HP |

200~400HP |

300~600HP |

|

Temp. Control |

6 zone |

6 zone |

7 zone |

8 zone |

8 zone |

|

Heating Capacity |

35KW |

42KW |

65KW |

90KW |

120KW |

|

Hydraulic Power |

3HP |

5HP |

5HP |

7.5HP |

7.5HP |

|

Max. Outpou/Hr |

100~250kg |

250~500kg |

400~800kg |

800~1500kg |

1000~1800kg |

|

Sub-extruder |

|||||

|

Screw Diameter L/D Ratio |

8~10 |

8~10 |

8~10 |

8~10 |

8~10 |

|

Power |

20~40HP |

40~50HP |

40~60HP |

60~100HP |

60~150HP |

|

Temp. Control |

3 zones |

4 zones |

5 zonesP |

6 zones |

6 zones |

|

Heating Capacity |

18KW |

22KW |

25KW |

37KW |

58KW |

|

Die Face Cutter |

|||||

|

Power |

2HP |

3HP |

3HP |

5HP |

7.5HP |

|

Separator |

|||||

|

Power |

10HP |

10HP |

10HP |

15HP |

20HP |

|

Vibration Motor |

|||||

|

Motor |

1/4HP*2 |

1/4HP*2 |

1/4HP*2 |

1/4HP*2 |

1/2HP*2 |

|

Blower |

|||||

|

Power |

5HP |

5HP |

7.5HP |

7.5HP |

10HP |

|

Storage Barrel |

|||||

|

Capacity |

1000L |

1000L |

1000L |

1000L |

1000L |

Manual open device for shredder tank when it comes power cut.

Sub extruder conducts second time filtering and ventilating for dirtier materials.

Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently.

High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity.

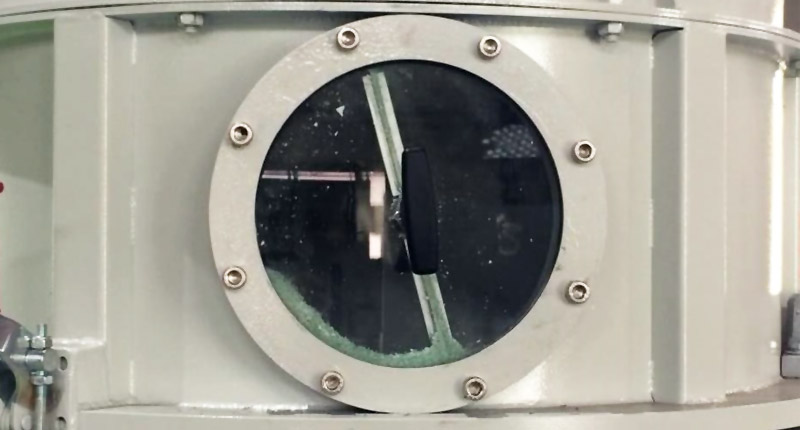

Shredder sight window with window wiper help operator to observe at anytime.

The main extruder provides the best feeding, mixing, ventilation, heating and capacity as it is designed way based on customer's raw material, capacity, compounding degree.

Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer.

The cyclone gathers the pellets and reduces the impact after high speed dryer prior to next vibrating screener.

The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole.

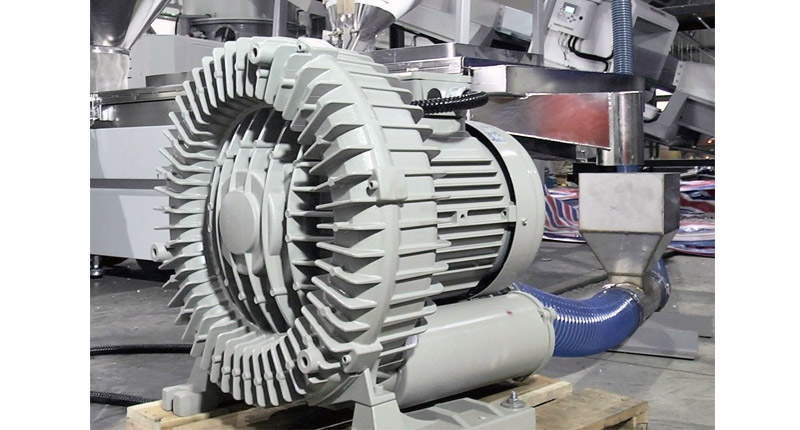

Blower with noiseless design.

|

|

| PE Agricultural Films | PE Agricultural Films |

|

|

| PE, LDPE, HDPE Film | PE, LDPE, HDPE Film |