- This liquid silicone injection molding machine is suitable for automobile parts, medical equipment, baby products, precision electronics, food containers and other products.

- Effectively reducing process times and increasing production capacity.

- PLC and HMI functional control as standard specification.

- The injection system used a three-stage pressure system and four speed transmission, proportional loop control, accurate precision injection volume with less than 0.5% difference, simple and convenient for operation.

- The acquisition loop hydraulic system with electronically controlled operation and a choice of using a servo motor for energy saving.

- Plunger feeding system, accurate AB material proportions, uniform mixing (transparency / tensile / uniform color), can improve product quality yield rate.

- Touch screen operation system, easy to setup, precise control, with 200 memory module settings.

- High-precision machining equipment make high quality liquid silicone products with a stable and high production rate.

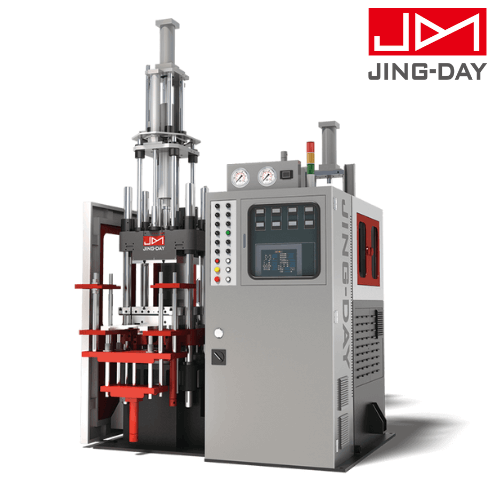

INTRODUCTION

JD-LS series liquid silicone vertical injection molding machine is a specialized type of equipment designed to mold liquid silicone rubber into desired shapes. It uses a vertical clamp and injection unit. This configuration allows for more precise control over the molding process, which involves injecting liquid silicone into a mold cavity, which then solidifies to create the desired product and enables the production of complex parts with high precision.

JD-LS series liquid silicone vertical injection molding machine consists of several essential components. The injection unit includes the barrel, screw, and nozzle, responsible for melting and injecting the liquid silicone rubber. The clamping unit comprises the mold, platens, and hydraulic system, which secures the mold and applies pressure during the injection process. Additionally, the control system manages and monitors the machine's operation, ensuring precise control over temperature, pressure, and timing.

SPECIFICATION

Factors to consider when choosing a liquid silicone vertical injection molding machine include the clamping force, injection volume, shot size, and mold size compatibility:

| MODEL | JD-LS65T | JD-LS80T | JD-LS200T | |

|---|---|---|---|---|

| Shot Volume | c.c. | 135 / 470 | 135 / 470 | 135 / 470 |

| Injection Pressure | kgf / cm² | 800 / 460 | 800 / 460 | 800 / 460 |

| Injection Cylinder Pressure | kg / cm² | 80 / 140 | 80 / 140 | 80 / 140 |

| Injection rate | c.c. / sec | 60 / 200 | 60 / 200 | 60 / 200 |

| Clamping Force | Ton | 65 | 80 | 200 |

| Plate Size | mm | 350 x 380 | 430 x 490 | 550 x 620 |

| Piston Diameter | mm | 200 | 230 | 355 |

| Piston Stroke | mm | 380 | 380 | 480 |

| Space Between Tie Bar | mm | 430 x 200 | 475 x 300 | 675 x 365 |

| Oil Hydraulic System | HP | 7.5 | 7.5 | 10 |

| Hot Oil Cycling Motor | kw | 0.5*2 | 0.5*2 | 0.5*2 |

| Platen Heating Capacity | kw | 7.6 | 9.6 | 20.8 |

| System Pressure | kg / cm² | 210 | 210 | 210 |

| Oil Tank Capacity | liters | 250 | 300 | 370 |

| Machine Dimensions | mm | 1300 x 900 x 2850 | 1680 x 980 x 1930 | 2830 x 2000 x 3940 |

| Machine Weight (Approx) | kg | 4100 | 5500 | 6500 |

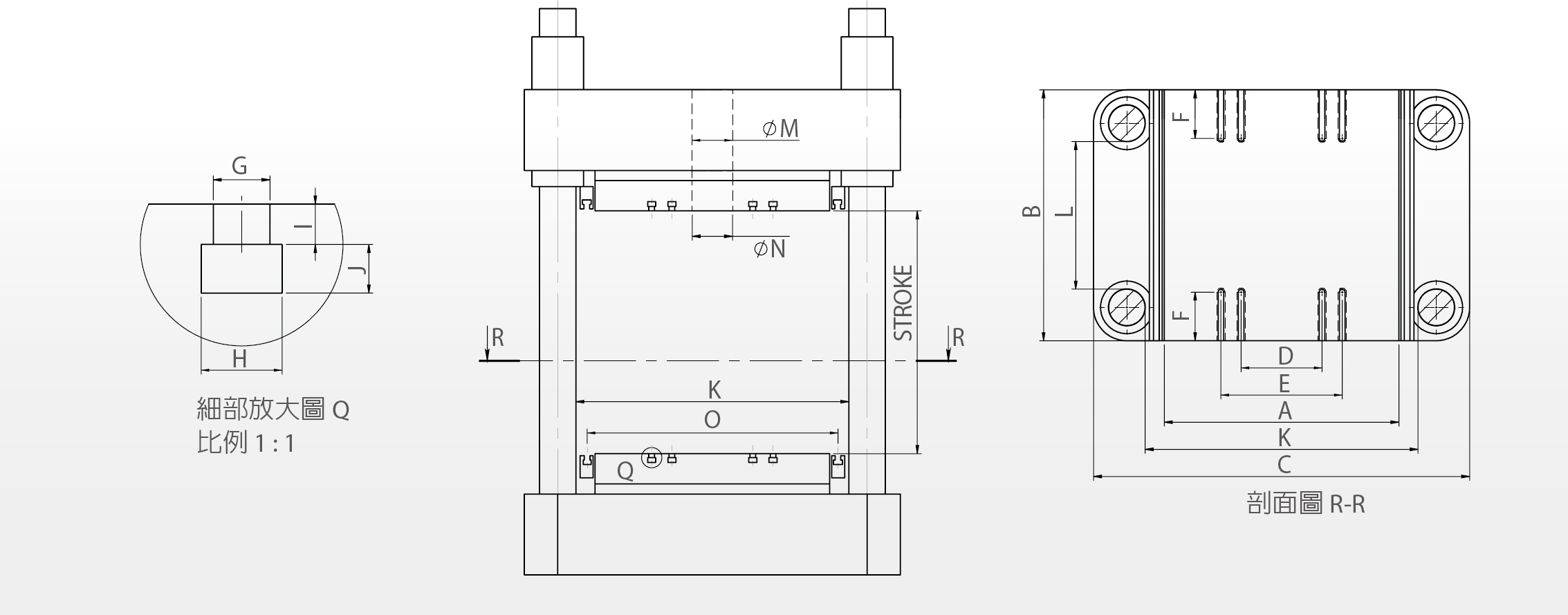

MOLD INSTALLATION & HEATING PLATE DIMENSION

| MODEL | JD-LS65T | JD-LS80T | JD-LS200T | |

|---|---|---|---|---|

| STROKE / DIMENSION | 380 | 380 | 480 | |

| A (mm) | 350 | 430 | 550 | |

| B (mm) | 380 | 490 | 620 | |

| C (mm) | 610 | 670 | 930 | |

| D (mm) | 150 | 200 | 200 | |

| E (mm) | - | - | 300 | |

| F (mm) | 90 | 135 | 120 | |

| G (mm) | 13 | 18 | 18 | |

| H (mm) | 21 | 25 | 25 | |

| I (mm) | 10 | 10 | 10 | |

| J (mm) | 11 | 12 | 12 | |

| K (mm) | 430 | 475 | 675 | |

| L (mm) | 200 | 300 | 365 | |

| M (mm) | 100 | 100 | 100 | |

| N (mm) | 70 | 80 | 86 | |

| O (mm) | 390 | - | 620 | |

It is important to select a liquid silicone vertical injection molding machine with sufficient clamping force to accommodate the size and complexity of the molds. The injection volume and shot size should align with the required material quantity for each part. Additionally, ensuring that the machine can accommodate the desired mold size is crucial for producing the desired products. If you have any needs or questions, welcome to contact us!