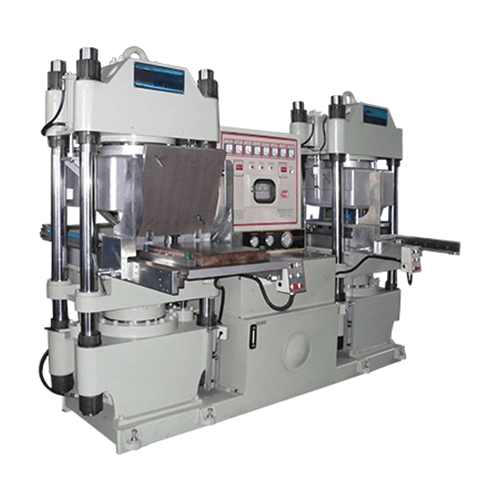

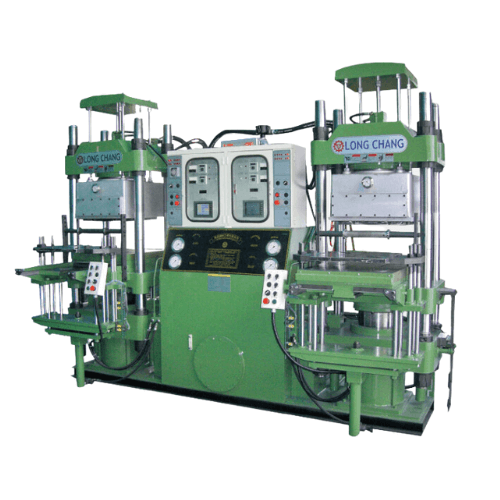

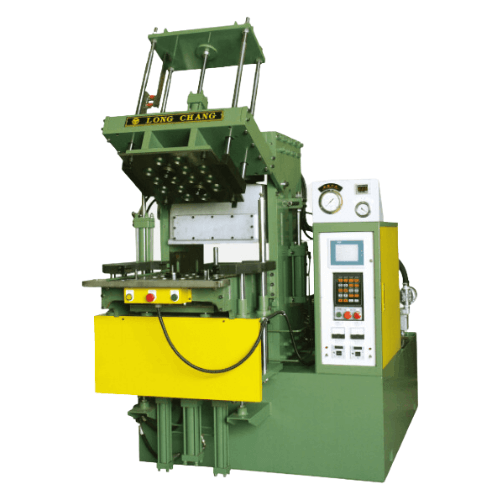

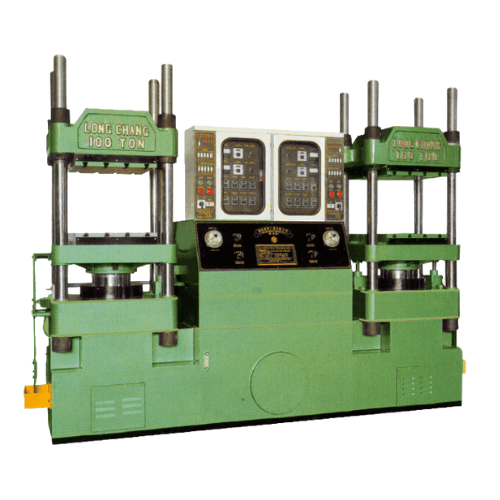

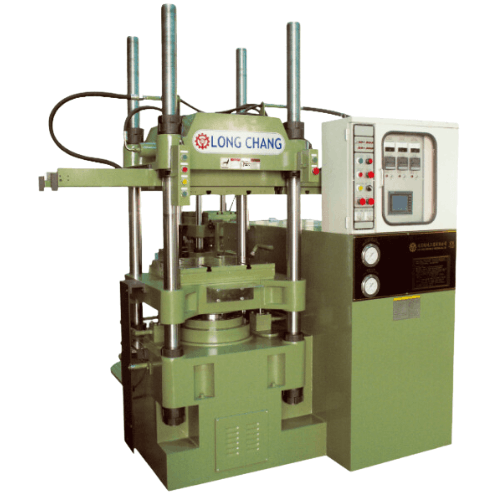

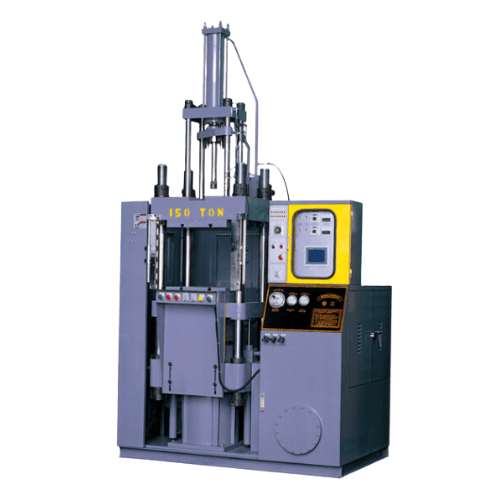

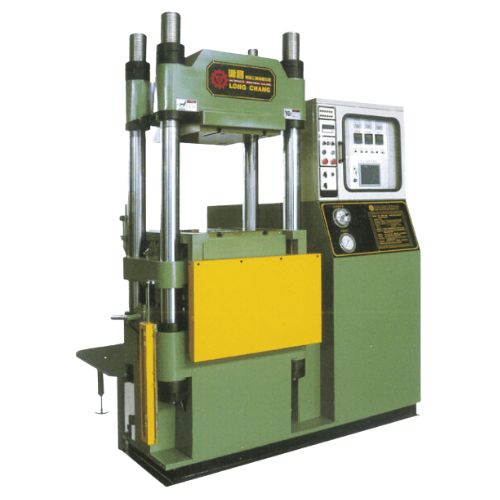

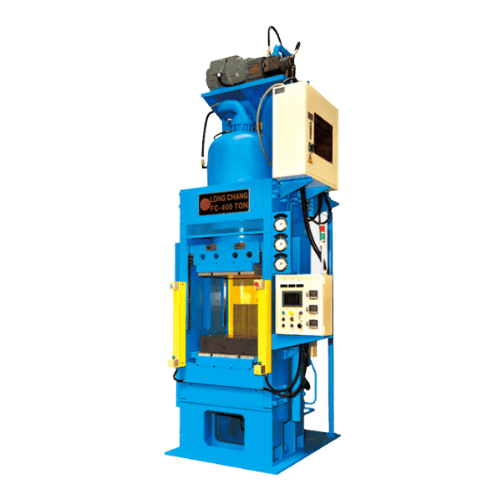

Classification : Vacuum Molding Machine

Country: Taiwan

Phone: 886-3-5372135

Fax: 886-3-5372381

Contact Person: Danny Lin

Vacuum capability

It is capable of being high percentage of vacuum. An Average vacuum method is adopted to make products steady and to promote the quality and throughput.

Mold opening design

A patent is granted for a new type rail mold opening. The opening angle is up to 90 degrees. It is very convenient for operation. Another feature of the new rail mold opening is that there is no need to remove the base of the rail mold opening while replacing molds. It promotes the work efficiency and safety.

Mold loading/unloading design

Incorporate a special design into the mechanism of mold loading/unloading. It is durable, quiet, speedy and stable.

Oil system design

Dual powers and individual oil system are adopted. Each oil system is designed respectively. It is steady, quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

Calibration

Two speeds of mold calibration are provided for users to choose from, fast and slow. It makes the calibration safer and more accurate.

It is capable of being high percentage of vacuum. An Average vacuum method is adopted to make products steady and to promote the quality and throughput.

Mold opening design

A patent is granted for a new type rail mold opening. The opening angle is up to 90 degrees. It is very convenient for operation. Another feature of the new rail mold opening is that there is no need to remove the base of the rail mold opening while replacing molds. It promotes the work efficiency and safety.

Mold loading/unloading design

Incorporate a special design into the mechanism of mold loading/unloading. It is durable, quiet, speedy and stable.

Oil system design

Dual powers and individual oil system are adopted. Each oil system is designed respectively. It is steady, quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

Calibration

Two speeds of mold calibration are provided for users to choose from, fast and slow. It makes the calibration safer and more accurate.

| Diameter of piston (mm) | 250 | 300 | 350 | 400 | 450 | 560 | 700 | 800 | 960 |

|---|---|---|---|---|---|---|---|---|---|

| Clamping force (ton) | 100 | 150 | 200 | 250 | 300 | 500 | 800 | 1000 | 1500 |

| Stroke (mm) | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 500 | 900 |

| Heating platen (mm) |

UP400*400 DN420*450 |

UP450*450 DN480*500 |

UP503*508 DN554*640 |

UP600*600 DN650*740 |

UP600*600 DN650*740 |

UP600*600 DN650*740 |

UP850*850 DN910*940 |

UP1000*1000 DN1200*1300 |

UP1500*1500 DN1800*1900 |

|

UP700*700 DN740*800 |

UP700*700 DN740*800 |

||||||||

| Horse (hp) | 7.5/10*1 | 10/15*1 | 10/15*1 | 10/15*1 | 10/10*2 | 15/15*2 | 20/20*2 | 20 | 30 |