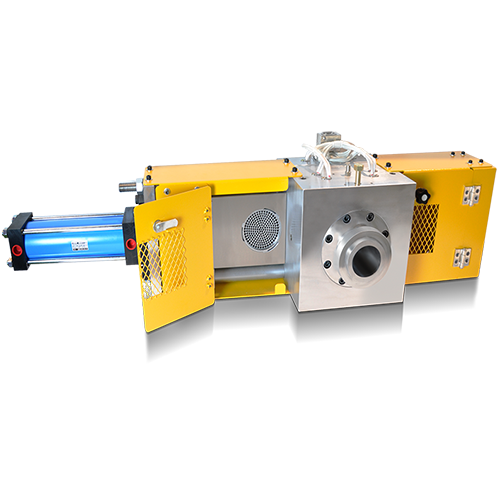

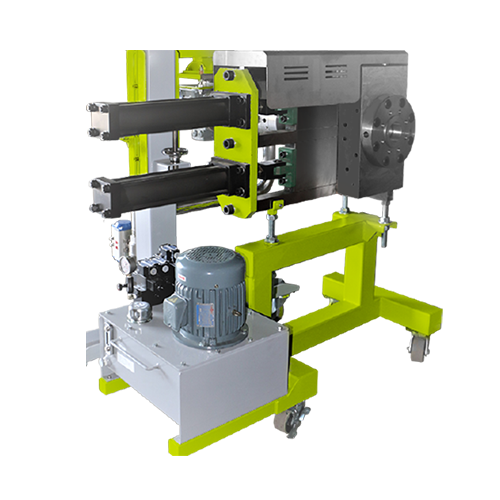

HYDRAULIC SLIDE PLATE

| Model | No 35 | No 45 | No 75 | No 100 | No 120 | No 150 |

| Inlet dia. | Ø 35 mm | Ø 45 mm | Ø 75 mm | Ø 100 mm | Ø 120 mm | Ø 150 mm |

| Filter dia. | Ø 48 mm | Ø 60 mm | Ø 113 mm | Ø 103 mm | Ø 150 mm | Ø 200 mm |

| Each hole dia. | Ø 4 mm | Ø 4 ~ 5 mm | Ø 4.5 ~ 5 mm | Ø 4 ~ 5.5 mm | Ø 4 ~ 5.5 mm | Ø 4.5 ~ 6 mm |

| Total watt |

3 heating

zone 1st zone 3600 W 2nd zone 1260 W 3rd zone 960 W |

3 heating

zone 1st zone 3600 W 2nd zone 1260 W 3rd zone 960 W |

3 heating

zone 1st zone 3600 W 2nd zone 1260 W 3rd zone 960 W |

3 heating

zone 1st zone 7600 W 2nd zone 2000 W 3rd zone 2000 W |

3 heating zone 1st zone 7600 W 2nd zone 2000 W 3rd zone 2000 W |

3 heating zone 1st zone 10150 W 2nd zone 2600 W 3rd zone 2060 W |

| Capacity | 25 ~ 70 KG | 55 ~ 135 KG | 125 ~ 310 KG | 125 ~ 310 KG | 270 ~ 650 KG | 540 ~ 1350 KG |

NON-STOP SLIDE PLATE

Model

No 35

No 45

No 75

No 100

No 120

No 150

Inlet dia.

Ø 35 mm

Ø 45 mm

Ø 75 mm

Ø 100 mm

Ø 120 mm

Ø 150 mm

Filter dia.

Ø 48 mm

Ø 60 mm

Ø 113 mm

Ø 103 mm

Ø 150 mm

Ø 200 mm

Each hole dia.

Ø 4 mm

Ø 4 ~ 5 mm

Ø 4.5 ~ 5 mm

Ø 4 ~ 5.5 mm

Ø 4 ~ 5.5 mm

Ø 4.5 ~ 6 mm

Total watt

3 heating

zone

1st zone 3600 W

2nd zone 1260 W

3rd zone 960 W

3 heating

zone

1st zone 3600 W

2nd zone 1260 W

3rd zone 960 W

3 heating

zone

1st zone 3600 W

2nd zone 1260 W

3rd zone 960 W

3 heating

zone

1st zone 7600 W

2nd zone 2000 W

3rd zone 2000 W

3 heating zone

1st zone 7600 W

2nd zone 2000 W

3rd zone 2000 W

3 heating zone

1st zone 10150 W

2nd zone 2600 W

3rd zone 2060 W

Capacity

25 ~ 70 KG

55 ~ 135

KG

125 ~ 310 KG

125 ~ 310 KG

270 ~ 650 KG

540 ~ 1350 KG

DUAL SLIDE PLATE

| Model | No 60 | No 80 | No 100 | No 120 |

| Inlet dia. | Ø 60 mm | Ø 80 mm | Ø 100 mm | Ø 150 mm |

| Filter dia. | Ø 66 mm | Ø 90 mm | Ø 110 mm | Ø 132 mm |

| Each hole dia. | Ø 4.5 mm | Ø 5 mm | Ø 5.5 mm | Ø 5.5 mm |

| Total watt |

2 heating

zone 1100W*4 pcs heaters 1100W*4 pcs heaters |

2 heating

zone 1300W*4 pcs heaters 1300W*4 pcs heaters |

2 heating

zone 1860W*4 pcs heaters 1860W*4 pcs heaters |

2 heating

zone 2100W*4 pcs heaters 2100W*4 pcs heaters |

| Capacity | 100 ~ 270 KG | 200 ~ 500 KG | 270 ~ 670 KG | 700 ~ 1200 KG |

DUAL PISTON

| Model | No 36 | No 42 | No 50 | No 65 | No 80 | No 100 |

| Inlet dia. | Ø 36 mm | Ø 42 mm | Ø 50 mm | Ø 65 mm | Ø 80 mm | Ø 100 mm |

| Filter dia. | Ø 46 mm | Ø 76 mm | Ø 96 mm | Ø 125 mm | Ø 160 mm | Ø 176 mm |

| Each hole dia. | Ø 4 mm | Ø 4 mm | Ø 5 mm | Ø 5 mm | Ø 6 mm | Ø 7 mm |

| Total watt |

1 heating

zone 180W*6 pcs heaters |

1 heating zone 1200W*6 pcs heaters |

1 heating zone 1200W*6 pcs heaters |

1 heating zone 1120W*6 pcs heaters |

1 heating zone 1200W*12 pcs heaters |

1 heating

zone 1480W*12 pcs heaters |

| Capacity | 25 ~ 60 KG | 60 ~ 250 KG | 160 ~ 350 KG | 300 ~ 700 KG | 600 ~ 1100 KG | 700 ~ 1500 KG |

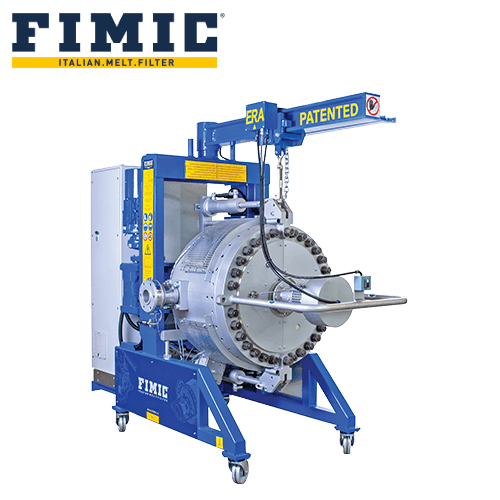

LARGE FILTRATION

| Model | No 50 | No 250 |

| Inlet dia. | 324*100 mm | 575*208 mm |

| Filter dia. | 3140*2 cm² | 11752*2 cm² |

| Total watt |

1 heating zone 1800W*6 pcs heaters |

2 heating zone 2340W*6 pcs heaters |

| Capacity | 800 ~ 1600 KG | 1000 ~ 3900 KG |

BACK-FLUSH

| Model | No 50 | No 65 |

| Inlet dia. | Ø 50 mm | Ø 65 mm |

| Filter dia. | Ø 96 mm | Ø 125 mm |

| Total watt |

2 heating zone 1200W*6 pcs heaters |

2 heating zone 2500W*6 pcs heaters |

| Capacity | 250 ~ 700 KG | 600 ~ 1300 KG |

MANUAL WITH LEVEL GEAR

Model

No 25

No 35

No 45

No 50

Inlet dia.

Ø 25 mm

Ø 35 mm

Ø 45 mm

Ø 50 mm

Filter dia.

Ø 51 mm

Ø 51 mm

Ø 51 mm

Ø 61 mm

Each hole dia.

Ø 3.5 mm

Ø 3.5 mm

Ø 4 mm

Ø 4 mm

Capacity

25 KG

40 KG

55 KG

65 KG

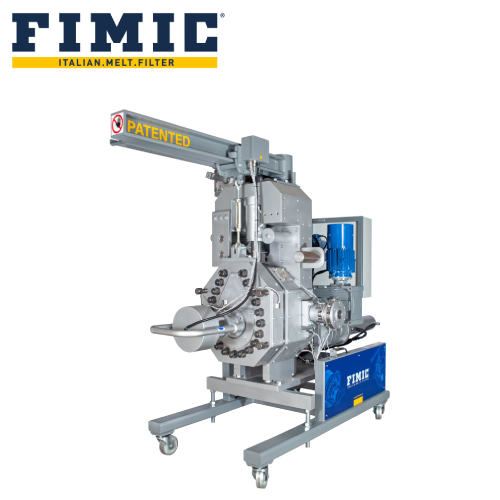

SELF-CLEANING FILTER

Model

No 38

No 70

No 80

Inlet dia.

Ø 38 mm

Ø 70 mm

Ø 80 mm

Filter dia.

173*87 mm

230*114 mm

340*145 mm

Each hole dia.

1418 cm²

2508 cm²

Total watt

2000W*2 pcs heaters

3300W*2 pcs heaters

5250W*2 pcs heaters

Capacity

50 ~ 100 KG

150 ~ 250 KG

230 ~ 500 KG

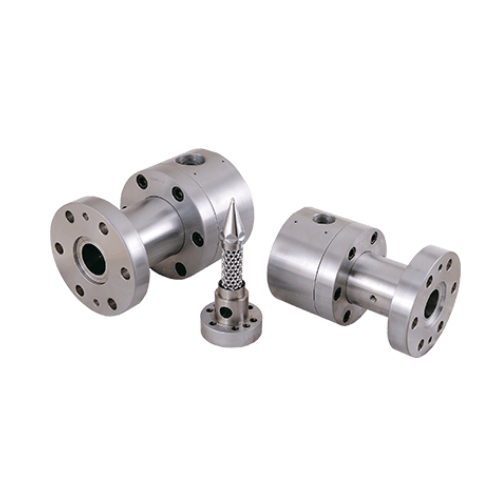

CANDLE TYPE

Filtering area: 191 ~ 231 cm²

Extrusion capacity: 100 ~ 600 kg/h

Heating method: Electric heating

- Hydraulic system, easy for operation.

- Optional guard cover to provide highest safety operation.

- Materials : most polymer.

- Application : for extrusion products such as sheet and films. Hydraulic system, easy for operation.

NON-STOP SLIDE PLATE

- Streamline and smooth channel for easy clean and little polymer stagnation.

- Interruption free and few bubbles caused by filter replacement.

- Hydraulic system with nitrogen accumulator for easy and fast operation.

- Fast slide plate movement for non-stop production.

- Materials : most polymer.

- Application : for extrusion products such as opitical, sheet and films.

- Continuous production process.

- Interruption free filter replacement.

- Hydraulic system is driven by solenoid valve for easy operation.

- Optional guard cover to provide highest safety operation.

- Materials : most polymer.

- Application : suitable for sheet products.

- Continuous production process, air does not enter the production process.

- Interruption free by filter replacement.

- Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system.

- Can be equipped with a fully automatic exhaust.

- Optional guard cover to provide highest safety operation.

- Materials : most polymer.

- Application : suitable for optical, sheet, film and other products.

- Continuous production process.

- Special venting design that no air enter the process during screen changing.

- Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system.Can be equipped with a fully automatic exhaust.

- Can be equipped with a fully automatic exhaust.

- The filter area is about 2~5 times larger than the Dual Piston.

- Optional guard cover to provide highest safety operation.

- Materials : most polymer.

- Application : suitable for granulation, sheet, film and other products.

- Interruption free filter replacement.

- Low pressure difference for stable and continuous production during filter replacement.

- Maintain 75% filtering area during filter replacement and backwash.

- Safety cover design improves operator safety.

- Automatic backwash and exhaust function for cutting filter replacement loss, operating requirements and scrap reduction.

- High wear-resistance, high pressure resistance, high-precision filter design provides effective filtering area and filter quality.

- Materials : most polymer.

- Application : suitable for recycle, granulation, packing tape and film.

- Easy operation with lever gear.

- Energy saving without driven system.

- Easy to clean when changing materials or colors frequently.

- Machine shutdown before filter replacement.

- Machine shutdown before filter replacement.

- Application : usually applied on sheet line, blow line and lab machine.

- Interruption free filter replacement.

- Large filtering area, applicable with a larger mesh count.

- Manual back wash. Energy saving without driven system.

- Materials : most polymer.

- Application : usually applied on sheet , lamination and film line.

- Compact mechanical design for higher mesh count to extend filter time.

- Manual network change, no hydraulic system.

- Adjustable pressure control during production to increase the effect of mixing in the screw.

- Application : applied on Lamination and film line.