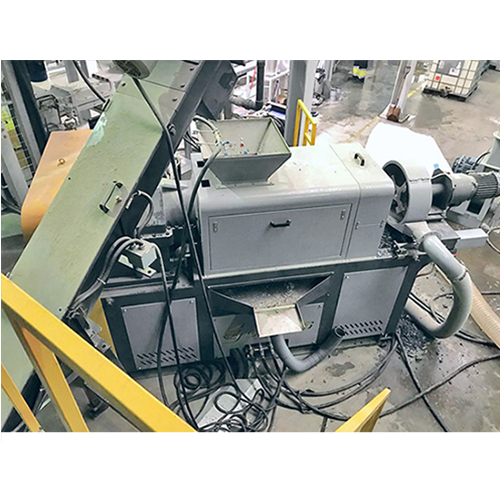

Plastic film screw press dryer is one of our best sellers. Squeezing process is one of the key factors in the efficiency of plastic extruders. The films produced by our plastic squeezer retain less moisture by 1% to 3%, so that with the utilization of plastic film screw press dryer will improve the quality of pellets significantly.

“The dryers where made to such a good standard .wanted to see if it's in all the machines you make. looking forward to coming to the next show so we can spend some time together” the owner of the company said.

The client’s feedback signifies the benefits of our product. High standard product quality, professional design team and advanced processing technology are essential to the success of our plastic film screw press dryer.

Country: South Africa

Related Machines: Plastic Squeeze Dryer

Currently, Genius Corporation has installed DW-300 squeeze dryer in Romania.

Even the water-washed plastic film via procedures of spin dryer still contains over 10% moisture whose material would reduce productivity of extruder and quality of pellets.

The latest development for recycling film: plastic film squeeze dryer which could make moisture to the minimum and the squeezed material only contains 3% moisture below.

This increases productivity of extruder and quality of recycled pellets. Hence; the biggest plastic corporation from Romania purchased the first plastic film squeeze dryer which will surely bring benefits and business.

Country: Romania

Related Machines: Plastic Squeeze Dryer

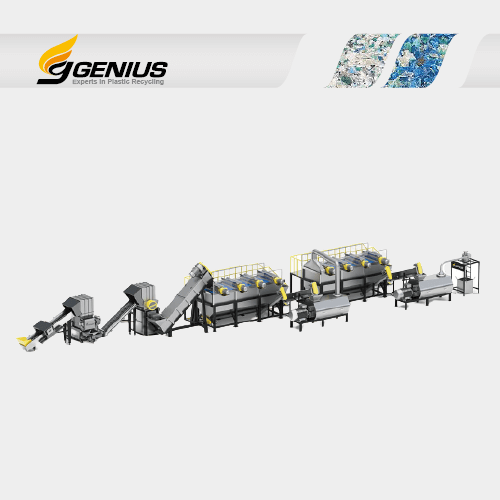

Cooperate with the clients’ washing line, install the plastic squeeze dryer in Spain.

In the late August in 2017, the plastic squeeze dryer had transported to the factory in Spain. This set of machinery is controlled by a Dual-way mix tank, two sets of DW-350 plastic squeeze dryer and SIEMENS HMI system. The output capacity can reach 1.5 ton per hour.

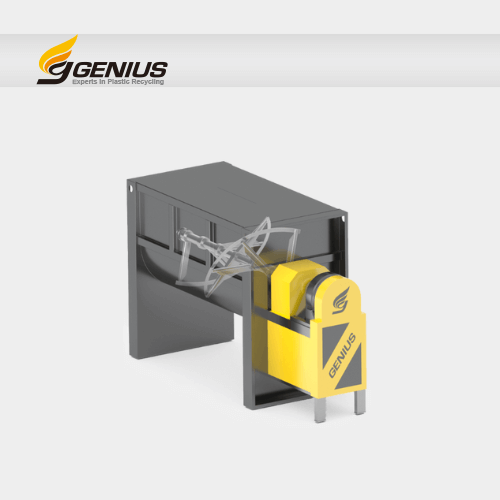

Dual-way mix tank

There are two DW-350 plastic squeeze dryer cooperate with the output of the washing line. The traditional way is to use Screw conveyor to send the washed film to the dryer. During the process, it may cause the problem of distributing material in a wrong average. In the end, the production efficiency can’t be increased. It also might happen that when the clean material is insufficient, people can’t use two dryer at the same time. The Screw conveyor might lead the inefficient cooperation.

Country: Spain

Related Machines: Plastic Squeeze Dryer

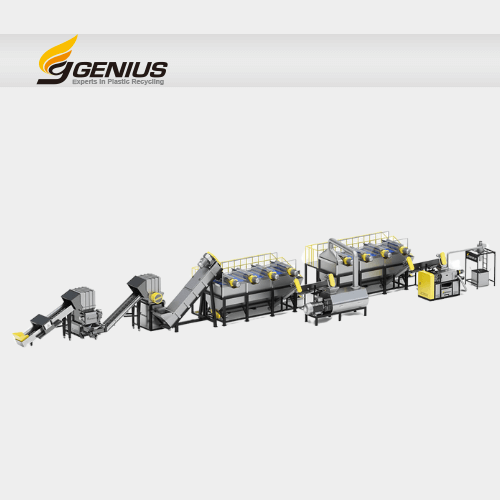

Japan generates about 9.03 million tons of plastic waste per year, and is the second largest plastics user in the world, second only to the United States. Faced with such a large amount of plastic waste, Japan’s waste recycling technology is quite refined (with about 80% recycling rate).

In recent years, the Ministry of the Environment of Japan has proposed a container recycling subsidy policy to encourage domestic industries to recycle plastic waste, thereby enhancing Japan’s position in the circular economy. Moreover, Genius’s squeeze dryer sales have grown significantly in the Japanese market in 2019. As of October, it had successfully sold 15 units.

Thanks to its user-friendly design, excellent performance and splendid production capacity, Genius’s smart recycling production line has been well received in 20 countries, including Japan,. Through the global sales network set up by local agents, Genius provides premium and reliable services to its clients.

Genius’s plastic recycling production line is entrusted to its Japanese agent “Pelletizing Technology Co., Ltd.”. The person in charge, Bill Kobayashi, has a background in machinery industry, and is familiar with Japanese manufacturing industry trends, as well as the country’s relevant regulations. He is well equipped in solving a whole variety of questions that customers may have regarding the production process and Genius’ products, thereby facilitating Genius’s sales performance in Japan.

Country: Japan

Related Machines: Plastic Squeeze Dryer