Classification : Molds and Dies

Country: Taiwan

Phone: 886-6-2795551

Fax: 886-6-2795553

Contact Person: Mr. Michael Chen

● Common mold base design makes the best use of the resources. 1, 2 ,3-cavity or 1, 2, 5-cavity can share the same mold base.

● Interchangeable insert mold design simplifies the mold changeover and repair, keeps the maintenance cost low and prolongs the lifetime of the mold.

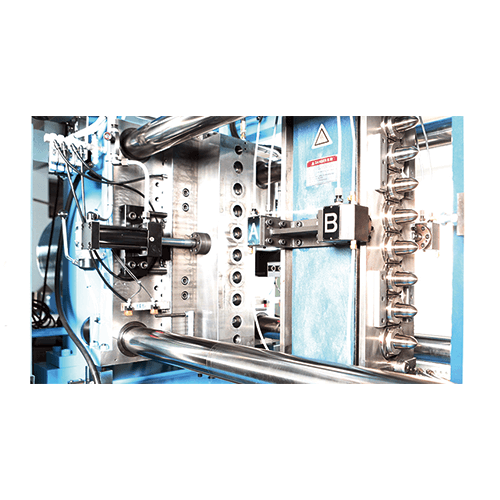

● Horizontal lock pins are highly durable, ensure precise mold parting line and enable easy mold opening and closing. (Pat. No. 92679)

● Valve gate hot runner system is designed with special anti-leaking device.

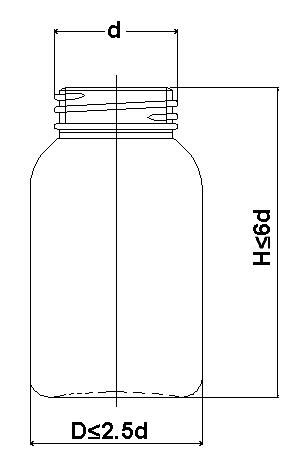

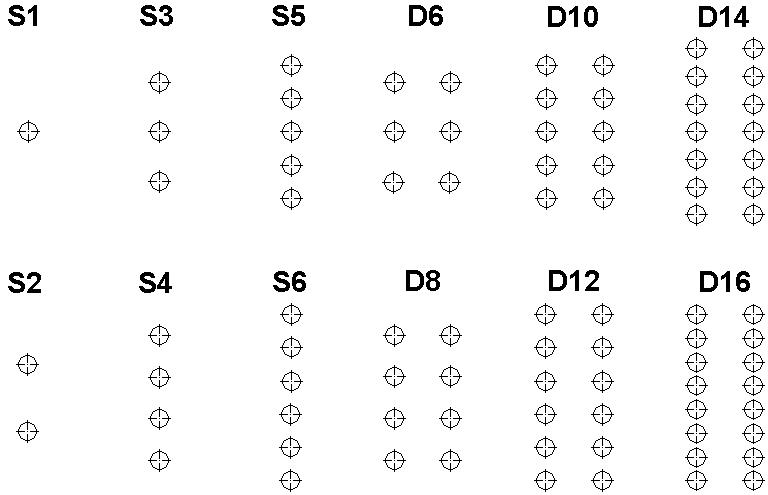

| Model No. | d Thread out Dia. /mm | D (Max.) /mm | H (Max.) /mm | Max. Cap./cc. | W.G./Gram | Cycle Timer/Sec. | Production/hour /Bottle |

| IB-100-S1 | 95 | 120 | 180 | 1600 | 120 | 22 – 40 | 90 – 160 |

| IB-100-S2 | 68 | 100 | 160 | 500 | 60 | 20 – 30 | 240 – 360 |

| IB-100-S3 | 55 | 95 | 160 | 360 | 40 | 16 – 28 | 380 – 670 |

| IB-100-S4 | 50 | 70 | 160 | 260 | 30 | 12 – 24 | 600 – 1200 |

| IB-100-S5 | 43 | 55 | 160 | 240 | 24 | 10 – 20 | 900 – 1800 |

| IB-100-S6 | 38 | 45 | 160 | 200 | 20 | 9 – 20 | 1100 – 2400 |

| IB-100-S7 | 25 | 40 | 150 | 120 | 17 | 9 – 18 | 1400 – 2800 |

| IB-100-S8 | 20 | 35 | 120 | 60 | 15 | 9 – 16 | 1800 – 3200 |

| IB-100-S10 | 17.5 | 30 | 100 | 40 | 12 | 9 – 14 | 2500 – 4000 |

| IB-100-S12 | 15 | 25 | 80 | 30 | 10 | 9 – 12 | 3600 – 4800 |

| IB-140-S1 | 125 | 200 | 200 | 3000 | 250 | 25 – 65 | 55 – 140 |

| IB-140-S2 | 100 | 180 | 175 | 1200 | 125 | 22 – 40 | 180 – 320 |

| IB-140-S3 | 80 | 150 | 175 | 700 | 80 | 20 – 30 | 360 – 540 |

| IB-140-S4 | 70 | 120 | 175 | 600 | 60 | 18 – 28 | 500 – 800 |

| IB-140-S5 | 60 | 95 | 175 | 400 | 50 | 17 – 27 | 670 – 1000 |

| IB-140-S6 | 50 | 75 | 175 | 320 | 40 | 16 – 24 | 900 – 1350 |

| IB-140-D8 | 55 | 80 | 150 | 300 | 30 | 12 – 18 | 1600 – 2400 |

| IB-140-D10 | 50 | 80 | 150 | 250 | 25 | 12 – 18 | 2000 – 3000 |

| IB-140-D12 | 40 | 75 | 150 | 200 | 20 | 12 – 18 | 2400 – 3200 |

| IB-140-D14 | 30 | 70 | 150 | 150 | 17.5 | 10 – 16 | 3100 – 5000 |

| IB-140-D16 | 25 | 50 | 150 | 80 | 15.5 | 10 – 16 | 3600 – 5700 |

| IB-140-D18 | 20 | 45 | 120 | 50 | 14 | 10 – 16 | 4000 – 6400 |

| IB-170-S1 | 150 | 300 | 300 | 12” Globe | 420 | 50 – 90 | 40 - 72 |

| IB-170-S2 | 80 | 150 | 250 | 8” Globe | 210 | 45 – 60 | 120 – 160 |

| IB-170-S3 | 70 | 120 | 250 | 6” Globe | 105 | 35 – 50 | 210 - 310 |

| IB-170-S4 / LED | 70 | 120 | 120 | 4” | 40 | 19 ~ 23 | 600 – 750 |

| IB-170-D8 / LED | 60 | 70 | 120 | 2” | 20 | 19 – 23 | 1200 – 1500 |

| IB-170-S8 / LED | 45 | 60 | 120 | 2” | 20 | 19 – 23 | 1200 – 1500 |

| IB-230-S1 | 160 | 400 | 450 | 16” Globe | 800 | 50 – 120 | 30 – 102 |

| IB-230-S2 / LED | 125 | 245 | 300 | 8” Globe | 400 | 45 – 60 | 30 – 80 |

| IB-230-S3 / LED | 95 | 160 | 300 | 6” Globe | 260 | 35 – 50 | 30 – 102 |

| IB-125Y-D14 | 35 | 53 | 110 | 180 | 9 | 7.5 – 8.5 | 5900 – 6700 |

| IB-125Y-D16 | 30 | 50 | 90 | 130 | 6.5 | 6.8 – 7.5 | 7600 – 8400 |

| IB-125Y-D18 | 24 | 40 | 80 | 60 | 5 | 6 – 6.3 | 10000 – 10800 |

※This list uses the molding shrinkage rate and specific gravity of Polystyrene (PS) as standard.

Above specifications are for reference only and may change according to the container design and overall size.