Model |

SC-550 |

SC-550-1 |

|---|---|---|

Pressing |

20-115mm |

20-115mm |

Horse Power |

5 hp |

7.5hp |

Pressure |

40 TONS |

70 TONS |

Dimensions of Machine L x W x H (mm) |

1150*1850*1730mm |

1250*2100*1730mm |

Working Area L x W (mm) |

550*650mm |

700*900mm |

Motor (HP) |

3-phase AC220V/380V |

|

Weight of Main Unit |

Approximately 2500kg |

Approximately 3000kg |

G.W. (Apr.) |

Approximately 2800kg |

|

G.W. (Approx.) |

Approximately 3300kg |

|

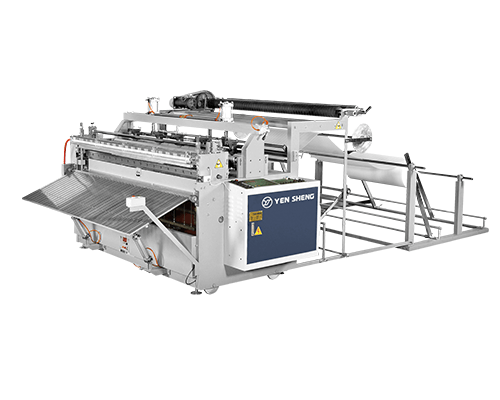

Classification : HYDRAULIC CUTTING MACHINE

Country: Taiwan

Phone: +886-4-779-5888

Fax: +886-4-779-5757

Contact Person: Sophie Lu

-

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

-

4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders.

-

The unit performs precisely, stably, quietly, nimble and powerful. lt's convenient even for the use at the upstairs of a factory.

-

Cutting depth can be precisely set up to a tolerance of 0.008 mm.

-

Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency

-

Processed items can be full or half cut-off. ltems with adhesive can be used as well. Products are free from rough edges.

-

The machine is equipped with a protecting device to ensure safety of people and the machine.

-

Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting.

-

Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks.

-

Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism.

-

Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings.

-

Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional).

-

High-precision German steel plate is used to achieve higher durability and wear free operation.

-

This machine uses advanced and durable hydraulic system and electronic control circuits.

-

The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

-

LCD(liquid crystal display), EL panel, soft print circuit boards, insulation spacers, self-adhesive labels, oil seals, membrane, thin films, PE foams, PVC, aluminum boards, polarizers, and high-precision trim presses for copper, aluminum and tin.

-

Thin film transistors: a wide range of high performance optical films.

-

Touch panels: optical adhesives, special adhesives, various printing film, ITO films, and sealants.

-

Electronics: FPC, HDI, RFPC, fiberglass, printing material, insulation, EMI material.

-

Conventional industries: Processing of foam plate, oil seal, sticker, or any material with a back adhesive.

-

This machine can be used to perform full-cut & half-cut high-precision cutting tasks for any materials (excluding metals).